Sealing cutter for thermal shrinkage film yardage roll packaging machine

A packaging machine and heat shrinkable film technology, applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of high cost, difficult assembly, and influence of sealing effect, achieve high temperature accuracy, and ensure cutting quality , The effect of saving the cost of mold opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

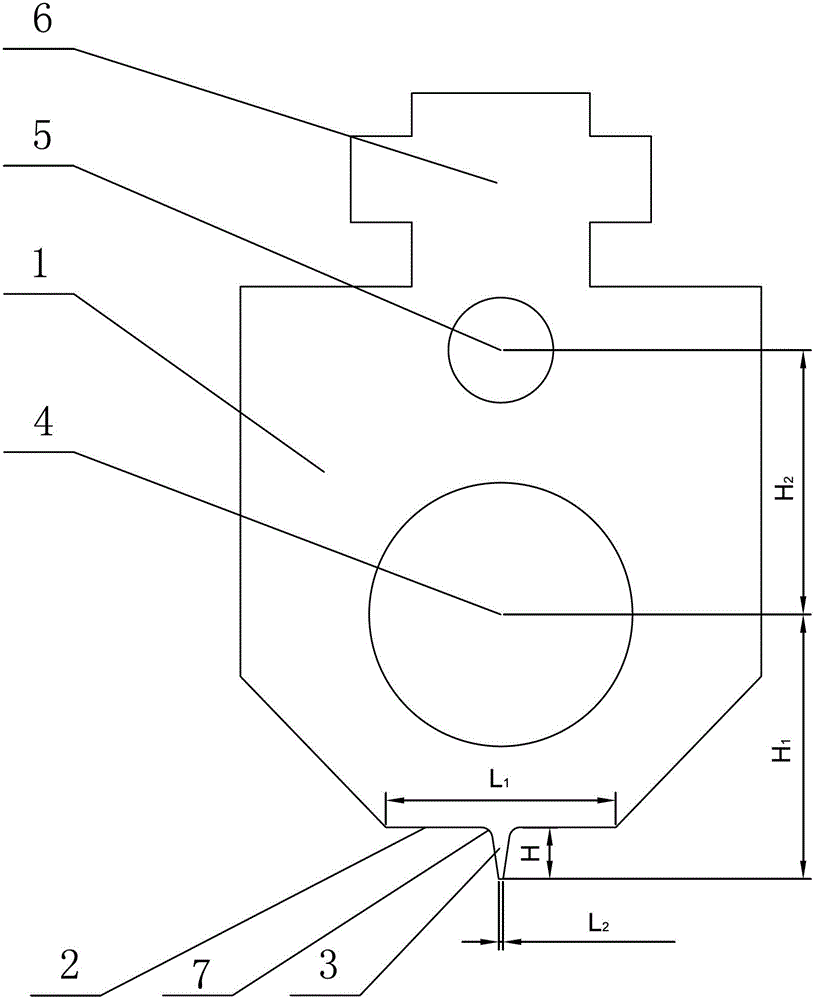

[0020] Embodiment one: if figure 1 As shown, a sealing and cutting knife for heat-shrinkable film cloth roll packaging machine includes a base 1, the lower end surface of the base 1 is a sealing surface 2, the sealing surface 2 is a plane, and a convex surface is integrally arranged on the sealing surface 2. The ribs 3 and the protruding ribs 3 are equal in length to the sealing surface 2 and divide the sealing surface 2 into two parts with the same width; The line connecting the center and the center of the thermocouple mounting hole 5 coincides with the central axis of the rib 3, and the vertical distance H between the center of the heating pipe mounting hole 4 and the top of the rib 3 1 The vertical distance H from the center of the thermocouple installation hole 5 to the center of the heat pipe installation hole 4 2 equal.

[0021] In this specific embodiment, the vertical distance H from the top of the rib 3 to the sealing surface 2 is 0.2 mm.

[0022] In this specific...

Embodiment 2

[0028] Embodiment 2: Other parts are the same as Embodiment 1, the difference is that the vertical distance H from the top of the rib 3 to the sealing surface 2 is 3 mm.

Embodiment 3

[0029] Embodiment 3: Other parts are the same as Embodiment 1 and Embodiment 2, except that the width L of the sealing surface 2 1 10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com