Centrifugal steel mould hub repairing process

A kind of repair technology and technology of wheel hub, which is applied in the field of repair of circular workpieces to achieve the effect of convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

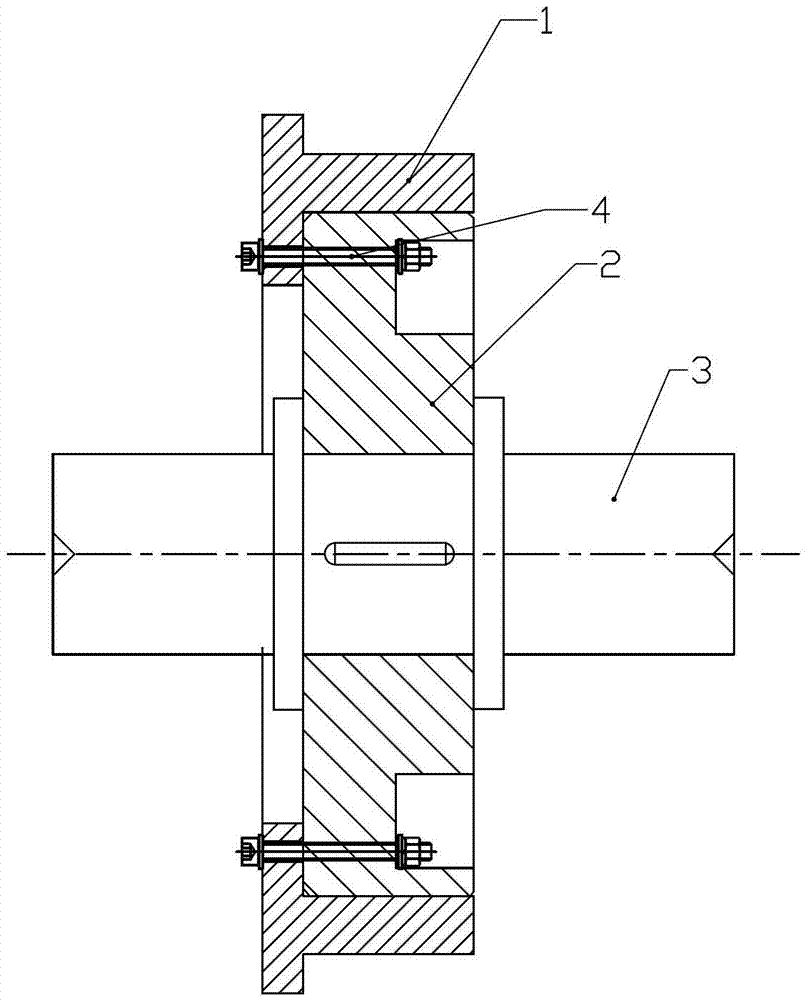

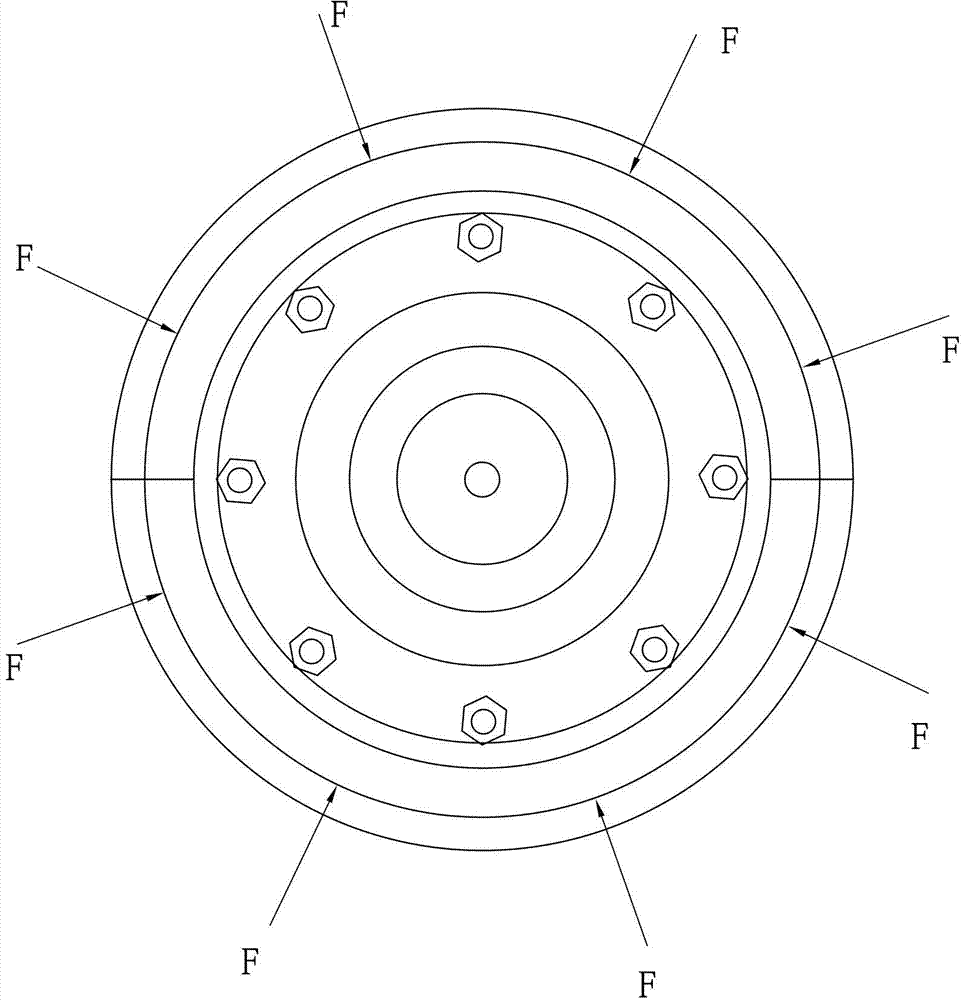

[0055] Such as figure 1 with figure 2 As shown,

[0056] The present invention aims to provide a freely foldable, centrifugal steel mold hub repair process. This method is to make a positioning mold 2 with a spindle 3 ( figure 1 ), the mold fixing disc is the same as the base flange of the fixed hub on the centrifugal steel mold. Simulating the base flange, fixing the hub on it is equivalent to moving the running wheel to the lathe for processing. The hub is usually formed by a combination of two semi-circular rings. First, we analyze the reason for the stress on the outer surface of the hub. During the long-term contact between the hub and the power wheel, the outer surface of the hub will generate tension or compressive stress. The role of the fastening bolts, the wheel hub fits on the centrifugal steel mold is not reflected in appearance, but in fact the wheel hub and the base flange of the centrifugal steel mold are tightly bonded together. When the centrifugal steel mold i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com