Spray shadowing for stress relief and mechanical locking in thick protective coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

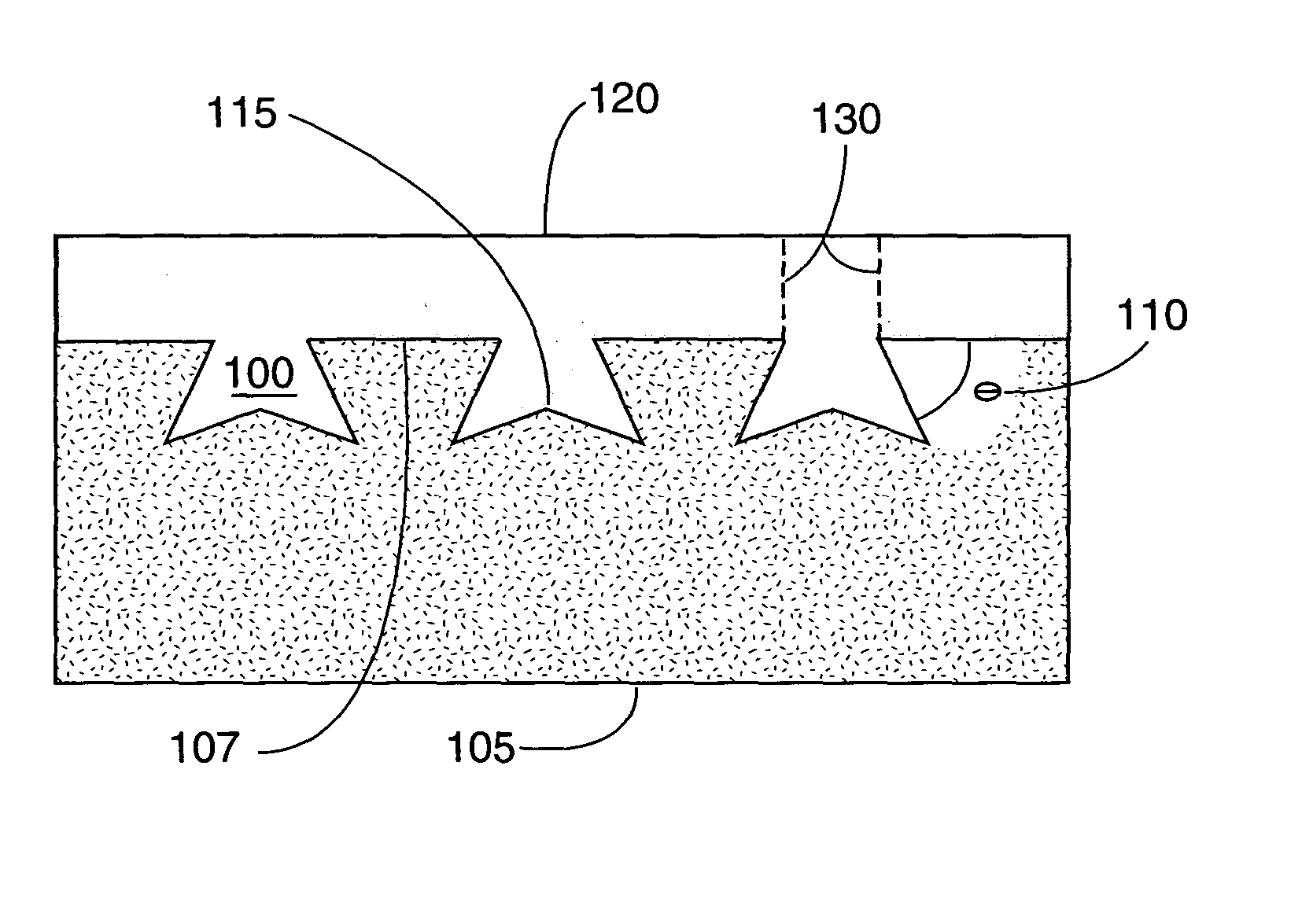

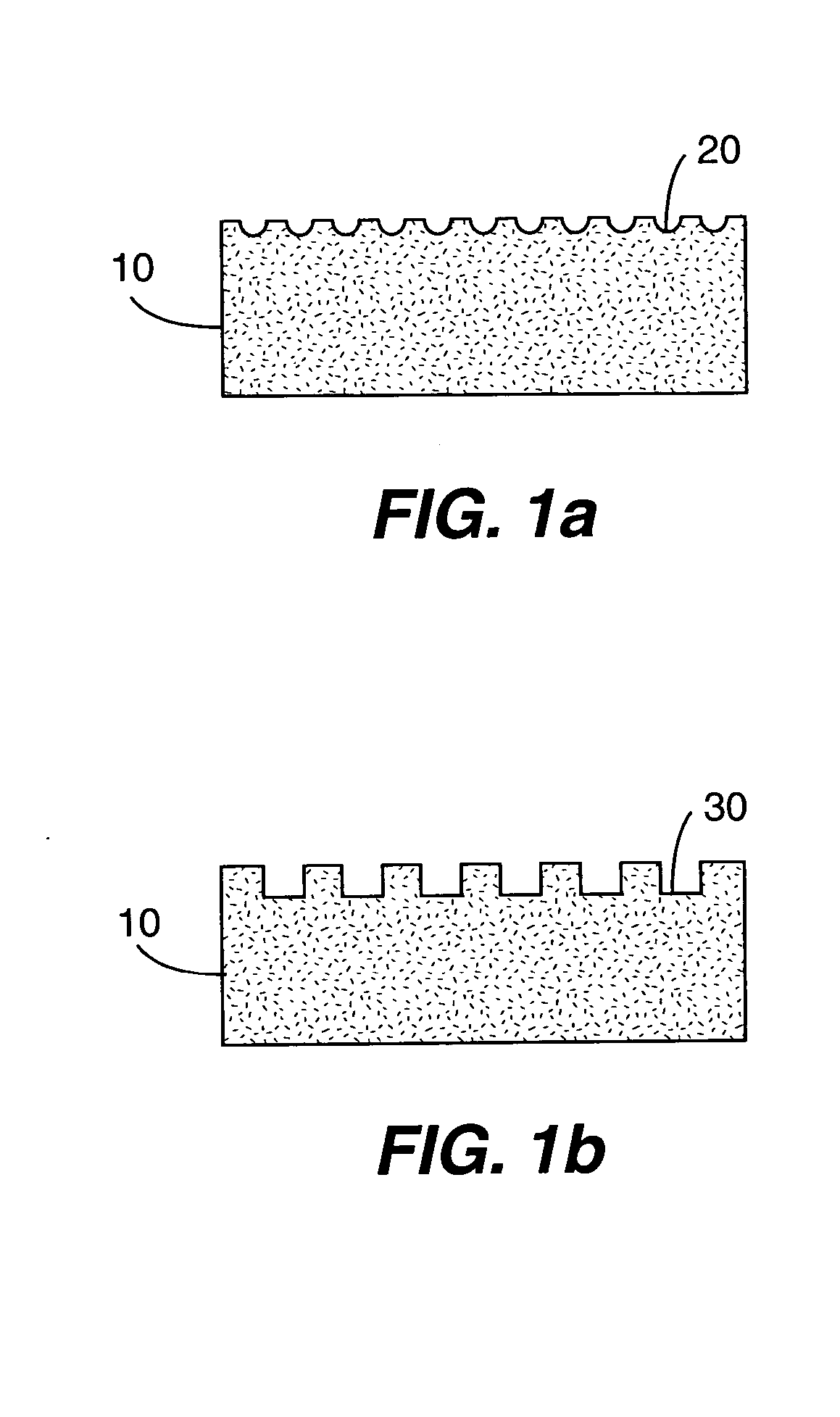

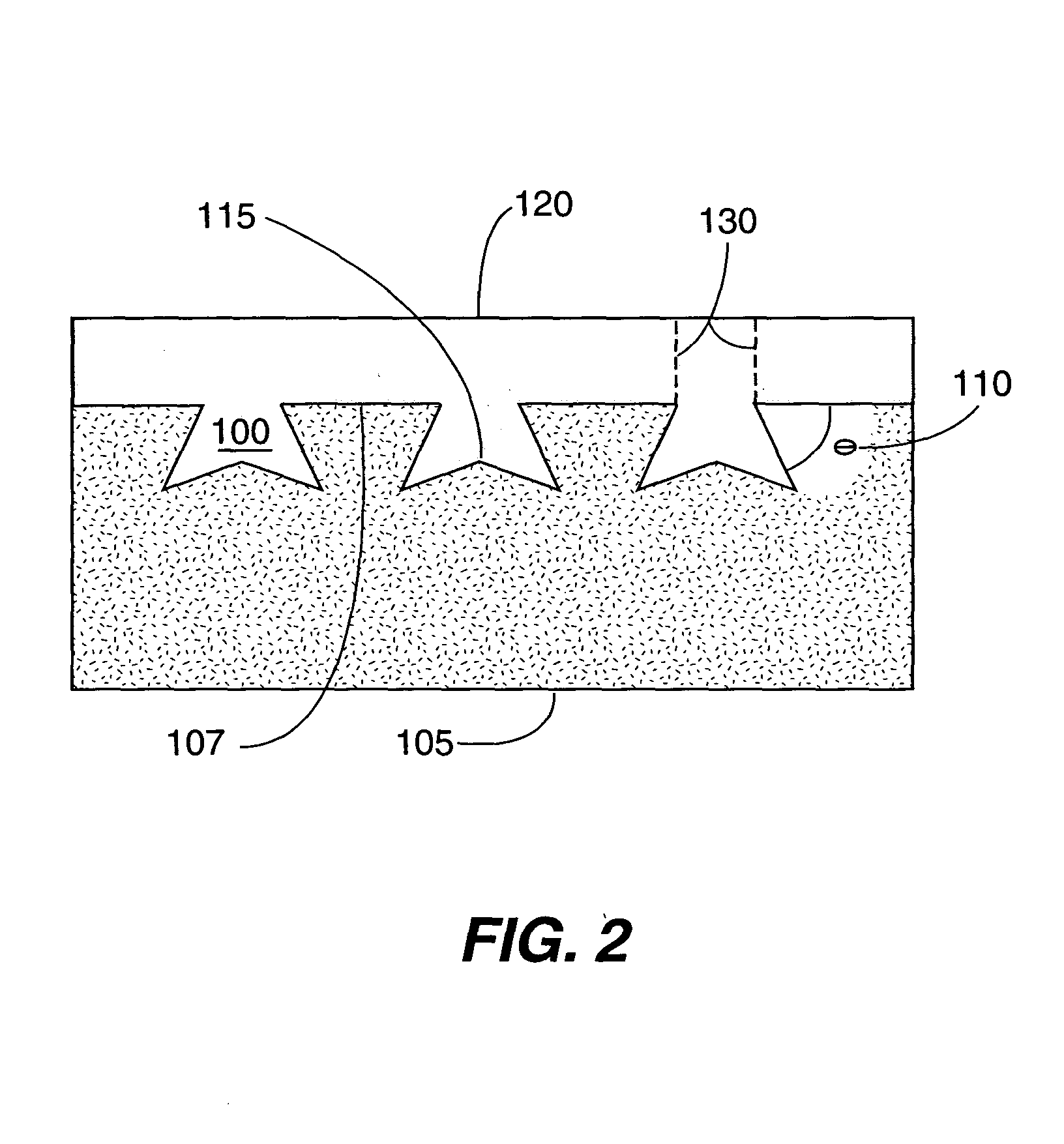

[0016] This present invention is a method, and corresponding article, that allows the buildup of thick, protective coatings by mechanically locking the coating to the underlying material, and avoids the debonding and spallation problems that normally limit the coating thickness that can be applied. Debonding is defined as a separation between the substrate and coating. Spallation is defined as removal of part of or all of the coating from the substrate, as a result of external thermal and physical forces. Furthermore, the present invention includes a beneficial feature, the formation of weak paths, which relieve stresses and strains experienced by a protective coating without experiencing full or partial debonding.

[0017] The existing technology for preparing substrates is to grit blast, chemically etch, laser roughen, or arc roughen the substrate prior to depositing a coating. These micro-roughening techniques are on the scale of 1 to 50 microns in feature dimension (height). Where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com