Cooling method of square and round billet continuous casting billet during tundish replacement

A cooling method, a billet continuous casting technology, applied in the cooling field of square and round billet continuous casting billets, can solve the problems such as inapplicable secondary cooling, achieve good promotion and application prospects, slow down the cooling intensity, and reduce the casting billet cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

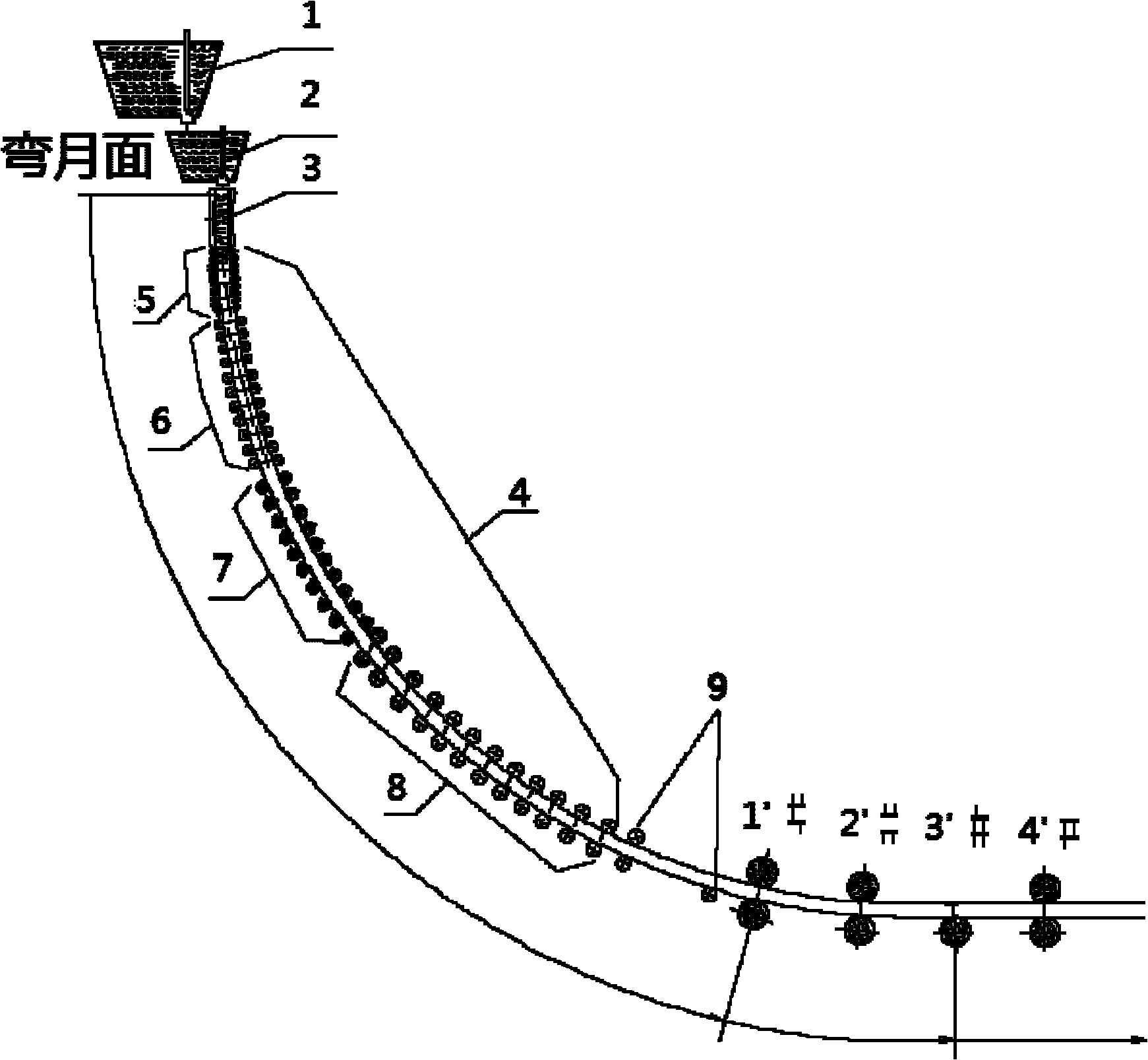

Method used

Image

Examples

Embodiment 1

[0037] This embodiment is used to illustrate the cooling method of the billet continuous casting cast slab in the tundish change process provided by the present invention.

[0038] The continuous casting section is 200mm×200mm, the steel material is 20CrMnTi gear steel before the package change, and the steel material is 45# steel after the package change. The chemical composition is shown in Table 1.

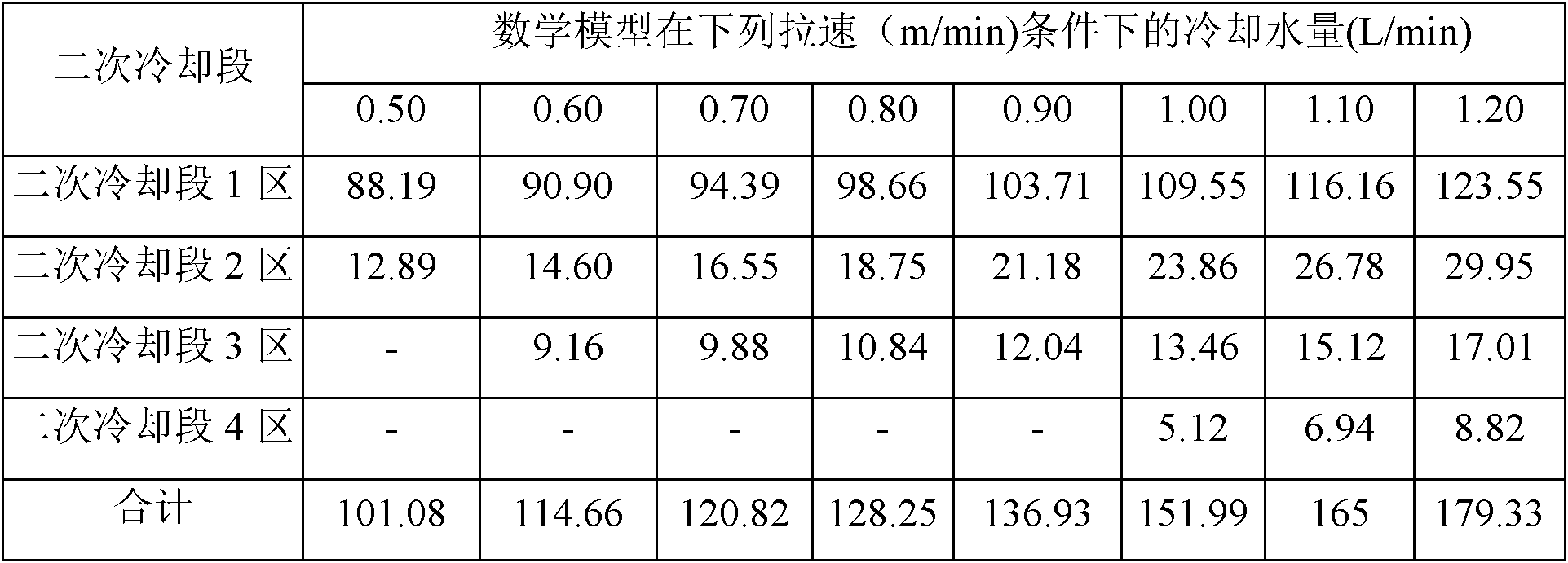

[0039] At the beginning of the tundish change, that is, after the crystallizer is shut down, the cooling water meter of the cooling system is switched to 1.2m / min before the shutdown of the 20CrMnTi steel, which corresponds to 80% of the cooling water volume of each zone in the secondary cooling section. Cooling for 1 minute (the amount of cooling water in each section of 20CrMnTi steel is determined by the pulling speed at the time. Depending on the pulling speed, the amount of cooling water in each zone also changes correspondingly. The specific cooling water amount in each zone co...

Embodiment 2

[0050] This embodiment is used to illustrate the cooling method of the billet continuous casting cast slab in the tundish change process provided by the present invention.

[0051] According to the method of Example 1, the billet continuous casting slab is cooled during the tundish change process. The difference is that the cooling water meter of the cooling system is switched to 20CrMnTi steel when the tundish change starts, that is, after the mold stops. The first 1.2m / min corresponds to 78% of the cooling water volume of each zone in the secondary cooling section of the drawing speed. Cool each zone in the secondary cooling section for 1.2 minutes. At this time, the water volume distribution of each spray cooling zone of the billet in the secondary cooling section is: The cooling water volume in the spray cooling zone is 89.82L / min, the cooling water volume in the second spray cooling zone is 22.86L / min, the cooling water volume in the third spray cooling zone is 12.76L / min, an...

Embodiment 3

[0054] This embodiment is used to illustrate the cooling method of the round billet continuous casting cast slab in the tundish replacement process provided by the present invention.

[0055] The continuous casting section is ¢200mm (the diameter of the section is 200mm), the pipe made of B steel before the change, and the pipe made of 37Mn2 steel after the change, the chemical composition is shown in Table 4.

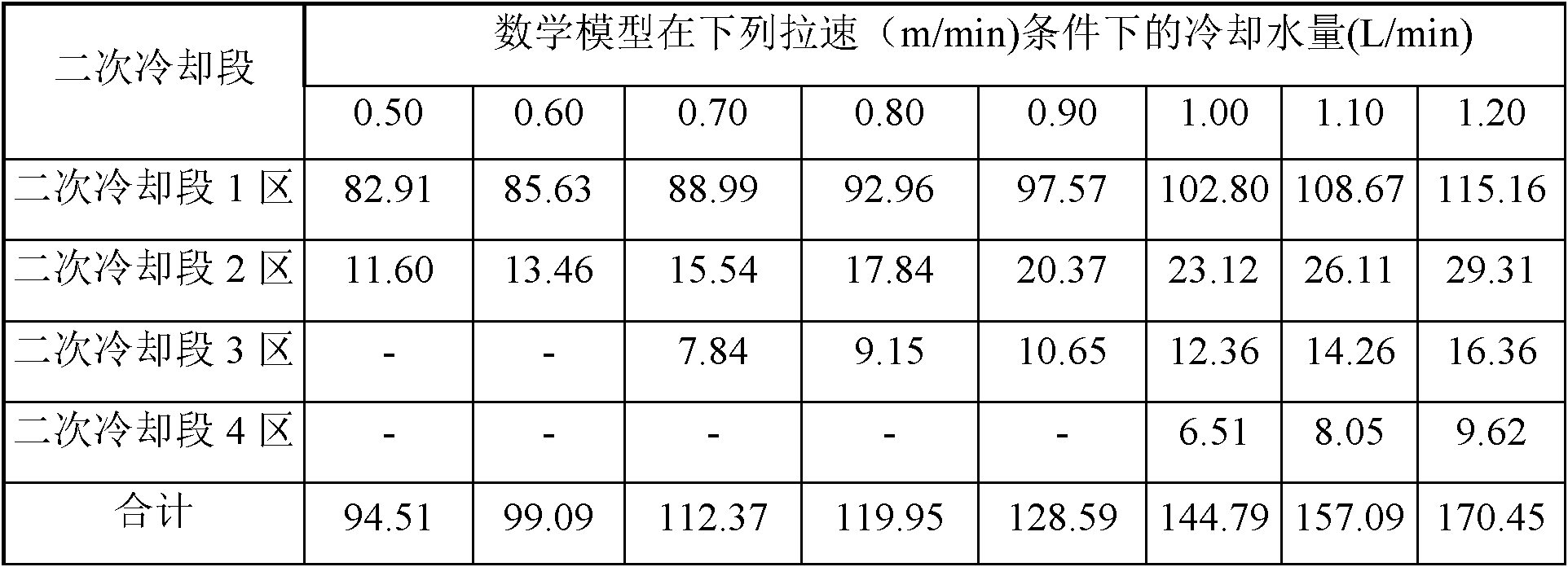

[0056] At the beginning of the tundish change, that is, after the crystallizer is shut down, the cooling water meter of the cooling system is switched to 1.2m / min before the shutdown of the B steel, which corresponds to 82% of the cooling water volume of each zone in the secondary cooling section. Cooling for 0.8 minutes (the amount of cooling water in each section of B steel is determined by the pulling speed at the time. According to the different pulling speed, the cooling water amount in each zone also changes correspondingly. The specific cooling water amount in each zo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com