Natto pigeonpea product preparation method using immobilized bacillus natto fermented pigeonpea seeds

A technology of natto bacteria and fermented beans, applied in the field of food science, can solve the problems of obvious side effects, drug resistance of the human body, and cannot be treated at the same time, and achieves the effect of good thrombolytic activity, delicious taste, and alleviating the problem of resource shortage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

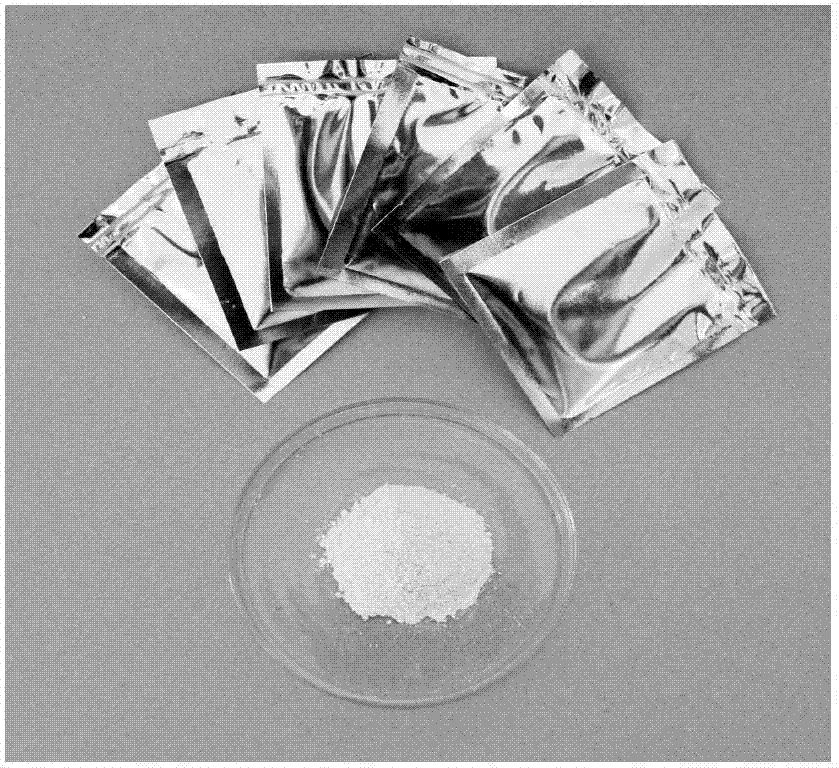

[0017] The preparation of example 1 fermented liquid and fermented soybean powder

[0018] (1) Preparation of pigeonpea seed liquid culture medium: 30g pigeonpea seeds are properly pulverized, weighed and put into a conical flask, add 300mL distilled water to soak overnight, adjust the pH of the medium to 6.5, and sterilize at 121°C for 40min at high temperature and high pressure After that, the temperature returned to room temperature for standby;

[0019] (2) Immobilized Bacillus natto fermented pigeonpea seeds: take 3.0mL of Bacillus natto bacteria solution and 6.0mL of sodium alginate solution with a concentration of 7.0% and fully mix, measure the mixed solution with a syringe and drop in chlorine with a concentration of 3.0%. In the calcium chloride solution, stir rapidly while dripping to form a well-shaped bacterium ball and let it stand for 2.0h, rinse it with distilled water to obtain a bacterium ball with an average diameter of 5.0mm and an average weight of 0.025g,...

example 2

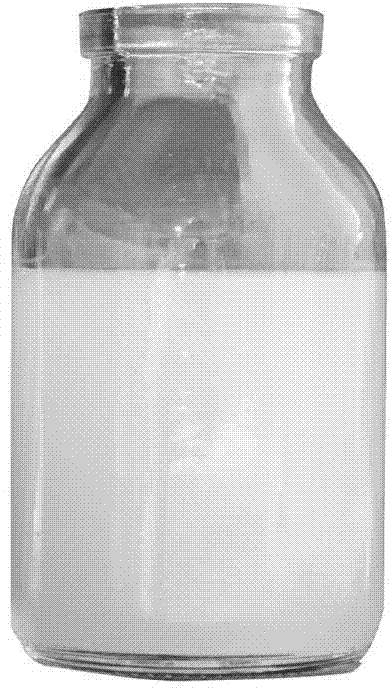

[0021] Example two liquid formulations—preparation of solution

[0022] 95 mL of fermented liquid was taken for seasoning, and the ingredients added included: 2.5 μL of edible essence, 25 mg of acesulfame potassium, 100 mg of xylitol, 20 mg of sorbitol and 15 mg of potassium sorbate. Then, different excipients were added to the seasoned fermented liquid, mainly including: 5.0 mL of propylene glycol (solvent), 4.0 g of gum arabic (emulsifier) and 0.1 g of sodium sulfite (antioxidant). After adding the excipients, stir well and evenly to obtain 100 mL of oral solution rich in nattokinase.

example 3

[0023] Example three solid preparations—preparation of granules

[0024] Take 5.0 g of fermented soybean powder for seasoning, and the added ingredients include: 7.0 mg of aspartame, 50 mg of xylitol, 25 mg of edible salt and 4.0 mg of protein sugar. Add 1.0 g of excipient maltodextrin (thickener) to the fermented soybean powder after seasoning, and stir thoroughly to obtain 6.1 g of meal replacement granules rich in nattokinase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com