Light-emitting/transmitting plastic lampshade and manufacture method thereof

A technology of luminescent pigments and lampshades, which is applied in the directions of luminescent materials, lampshades, chemical instruments and methods, can solve the problems of opacity and reduced light transmittance of luminescent pigments, and achieve the effect of high luminous brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

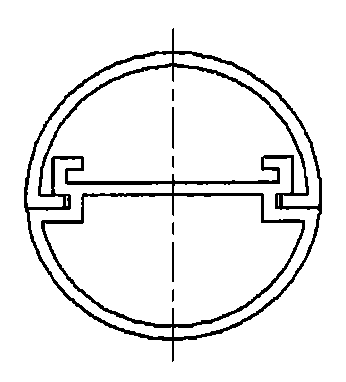

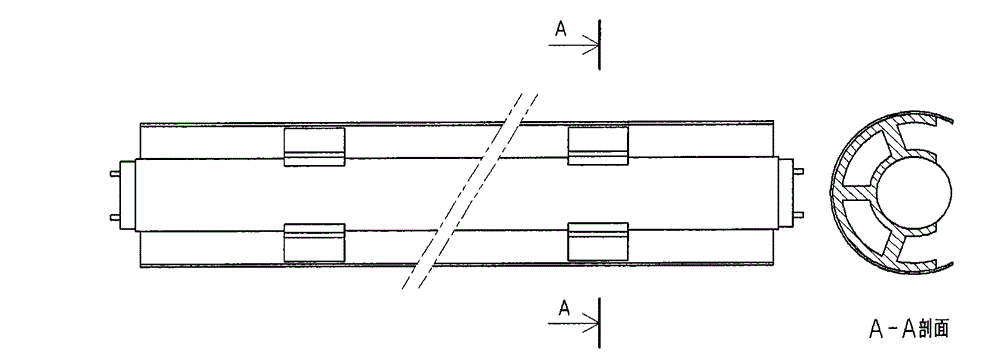

Image

Examples

example 1

[0072] Example 1: This example is the application of extrusion molding to manufacture light-emitting lampshades.

[0073]

[0074] Among them, PC-30 luminescent plastic masterbatch contains 30% SrAl 2 o 4 :Eu 2+ , Dy 3+ Luminescent pigment, the average particle size of luminescent pigment is 30μm, and the brightness is 340mcd / m2 in 10 minutes.

[0075] Take 10kg of luminescent plastic masterbatch PC-30 and 8.34kg of PC2805 resin and dry at 80 degrees for 8 hours. Add the resin and other materials into a high-speed mixer and stir for 8 minutes at a speed of 860 rpm to distribute evenly at high speed. The mixed raw materials are extruded at 240-270° C. to make a luminescent lampshade with a thickness of 1.35 mm.

[0076] The processing temperature is as follows:

[0077] Location

Feeding section

compressed section

Plasticizing section

Die

temperature / ℃

240~270

250~270

260~270

260~270

250~270

[0078] ...

example 2

[0082] Example 2: This example is the application of extrusion molding to manufacture luminescent and transparent lampshades.

[0083]

[0084]

[0085] Among them, the average particle size of the luminescent pigment is 90 μm, and the brightness is 600 mcd / m2 in 10 minutes.

[0086] Put other materials except luminescent pigments into a high-speed mixer and stir for 10 minutes at a speed of 860 rpm to distribute evenly at high speed. Then, the mixed material and the luminous pigment were stirred for 1.5 hours in a drum type plastic mixer at a speed of 30 rpm. The mixed raw materials are extruded into 1.8mm thick luminescent lampshade profiles according to the processing temperature of the following sections.

[0087] Processing temperature of each section:

[0088] Location

Feeding section

compressed section

Plasticizing section

Die

temperature / ℃

150~160

180~190

195~205

195~205

205~210

[0089] Trac...

example 3

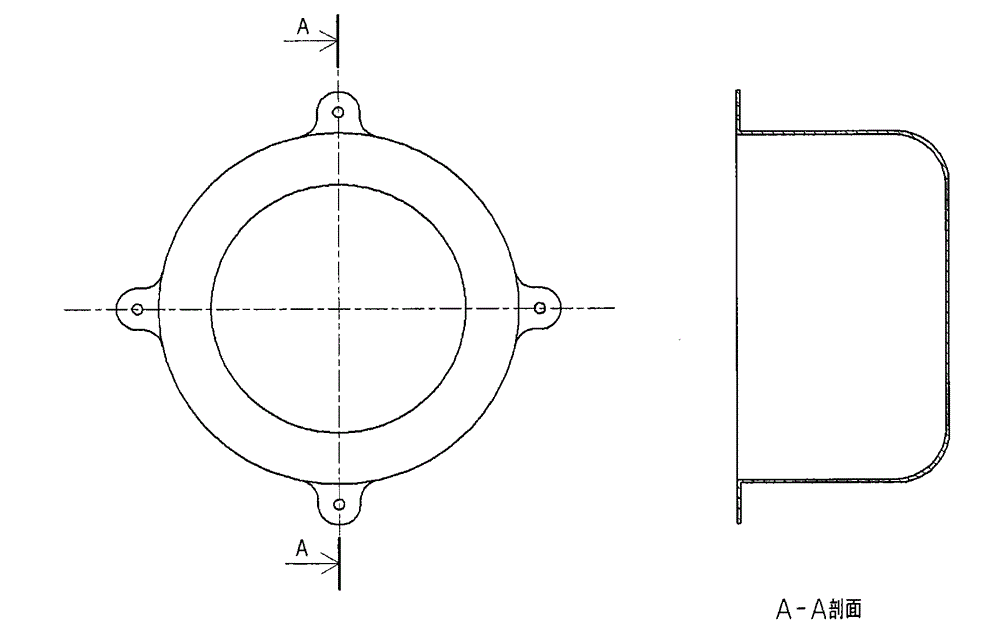

[0092] Example 3: This example is the application of injection molding to manufacture luminescent and transparent lampshades.

[0093]

[0094] Among them, the average particle size of the luminescent pigment is 90 μm, and the brightness is 660 mcd / m2 in 10 minutes.

[0095] Dry the PMMA resin at 85°C for 6 hours. Add other materials into a high-speed mixer (without luminescent pigments), and disperse evenly at high speed, then add luminescent materials and stir evenly, and the dispersion time should be short. The mixed raw materials are made into a luminous lampshade with a thickness of 3mm through injection molding process, such as image 3. The lampshade is also heat treated at 80°C for 6 hours to eliminate internal stress.

[0096] The injection processing parameters are as follows:

[0097]

[0098] Its luminous properties and light transmission properties are as follows:

[0099]

[0100] The lampshade can be in accordance with Figure 3 shown, bolted to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com