Bacillus subtilis and method for fermentation production of D- ribose

A technology of Bacillus subtilis and ribose, applied in the field of microbial fermentation, can solve the problems of high residual sugar, easy to produce spores, long fermentation cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Cultivate Bacillus subtilis ATCC21360 on a slant medium at 35-38°C for 2 days, scrape the bacterial cells into sterile saline, and make a bacterial suspension with a cell concentration of 1×10 8 ~10 9 individual / mL. According to conventional mutagenesis methods, physical and chemical mutagens such as ultraviolet lamps and nitrosoguanidine are used for alternate phase or continuous treatment. Take the above-mentioned bacterial suspension in a Petri dish, place it under a 15W ultraviolet lamp at a distance of 20cm, and irradiate it for 0.5-5 minutes; take the above-mentioned bacterial suspension and treat it with 1 mg / mL nitrosoguanidine solution, and incubate and shake at 35-38°C for 30 minutes. For ~60 minutes, centrifuge the cells treated with nitrosoguanidine and wash them with normal saline several times to remove residual nitrosoguanidine. Spread the bacterial solution treated with ultraviolet light, nitrosoguanidine alternately or continuously on the plate medium...

Embodiment 2

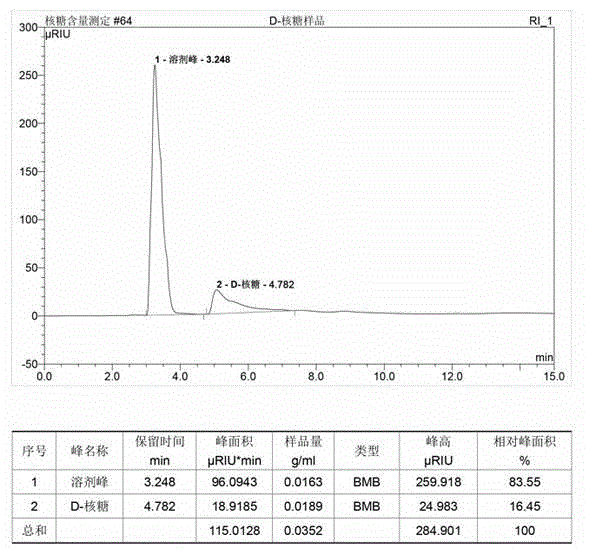

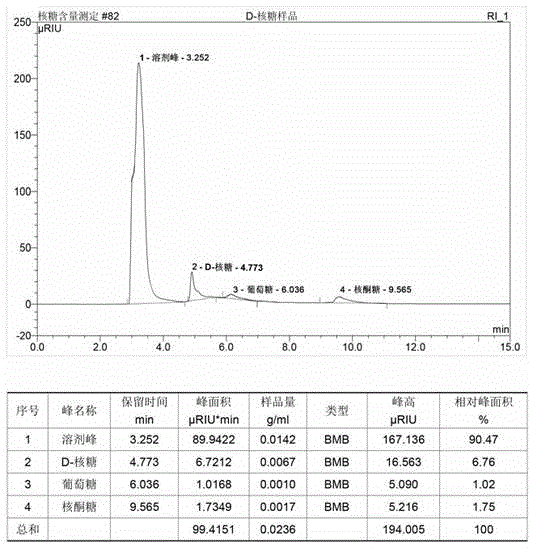

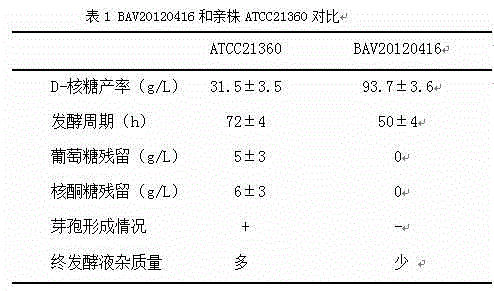

[0049] The Bacillus subtilis transketolase-deficient mutant strain BAV20120416 obtained by mutagenesis was inoculated on a slant medium, and cultured at 36° C. for 2 days to obtain a slant strain. Take a ring of slant bacteria and inoculate it into a 500mL Erlenmeyer flask containing 50mL of seed medium, culture it on a shaker at 36°C and 150 r / min for 14 hours, and insert 10% of the inoculum into the pre-prepared 500mL fermentation medium In a 5L shake flask, at 36°C, with a speed of 150r / min, the shaker fermentation culture was carried out. After 48 hours of fermentation, the glucose content in the fermentation broth dropped to 0, and the D-ribose content reached 90.2g / L; while its parent strain Under the same conditions, ATCC21360 needs to be cultured for 72 hours, and the glucose content in the fermentation broth will not drop after it drops to 4 g / L, and the D-ribose content in the fermentation broth is only 29.7g / L.

[0050] The above slant medium composition (%): pepton...

Embodiment 3

[0054] The Bacillus subtilis transketolase-deficient mutant strain BAV20120416 obtained by the above mutagenesis was inoculated on the slant medium of eggplant bottles, and cultured at 37° C. for 2 days to obtain a large slant strain. Add sterile water to the eggplant bottle to wash the strains to make a bacterial suspension, inoculate the bacterial suspension into a 5L shaker flask with 800mL of seed medium, and culture it on a shaker at 37°C with a speed of 150r / min for 16 hours , put 10% of the inoculum into the pre-prepared fermentation medium, the 50L fermentation tank has a liquid volume of 30L, and carry out ventilation and stirring culture at 37°C, wherein the stirring speed is 200~300r / min, and the ventilation volume is 1~2Nm 3 / h, the pressure in the tank is 0.05Mpa, the initial pH of the fermentation broth is 6.5~7.2, the pH of the fermentation broth is controlled at 5.4~7.0 by adding acid and alkali during the fermentation process, and the glucose and D-ribose in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com