Cunninghamia lanceolata cultivation compound substrate and preparation method for same

A technology of composite matrix and Chinese fir, which is applied in the direction of fertilizer mixture, preparation of organic fertilizer, organic fertilizer, etc., can solve the problems of waste of resources, etc., and achieve the effect of benefiting growth, strong cushioning, and resisting damage to plant roots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

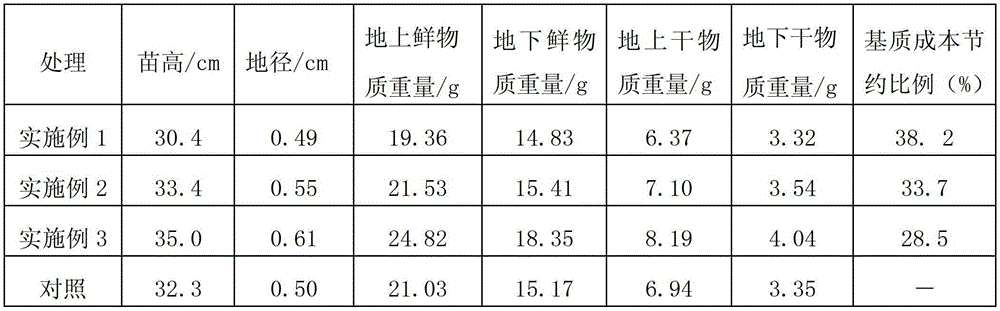

Examples

Embodiment 1

[0024] Mix 100 parts by weight of 3 mesh cedar bark powder, 200 parts by weight of tung bran, 10 parts by weight of calcium magnesium phosphate fertilizer, 0.05 parts by weight of slaked lime powder, 0.04 parts by weight of enzyme bacteria, and 0.1 parts by weight of corn flour, mix well, add moisture and cover The plastic film is piled for 15 days to obtain fermented fir bark powder for later use.

[0025] Mix 100 parts by weight of 8 mesh cedar bark powder, 2 parts by weight of urea, 0.02 parts by weight of hydrated lime powder, and 0.01 parts by weight of 95% dixone wettable powder, mix well, add water, and cover the plastic film for 20 days to obtain adsorption Chinese fir bark powder is reserved.

[0026] Mix 10 parts by weight of rice bran, 0.01 parts by weight of boletus edulis and 0.01 parts by weight of boletus edulis, mix well, add water, and cultivate for 10 days to obtain amplified ectomycorrhizal fungi for later use.

[0027] 2 parts by weight of fermented cedar bark po...

Embodiment 2

[0029] Mix 100 parts by weight of 5 mesh cedar bark powder, 200 parts by weight of tung bran, 10 parts by weight of calcium magnesium phosphate fertilizer, 0.05 parts by weight of slaked lime powder, 0.04 parts by weight of enzyme bacteria, and 0.1 parts by weight of corn flour, mix well, add moisture and cover The plastic film is piled for 18 days to obtain fermented fir bark powder for later use.

[0030] Mix 100 parts by weight of 10 mesh cedar bark powder, 2 parts by weight of urea, 0.02 parts by weight of hydrated lime powder, and 0.01 parts by weight of 95% dixon wettable powder, mix well, add water, cover the plastic film and pile for 25 days to obtain adsorption Chinese fir bark powder is reserved.

[0031] Mix 10 parts by weight of rice bran, 0.01 parts by weight of boletus edulis and 0.01 parts by weight of boletus edulis, mix well, add water, and cultivate for 13 days to obtain amplified ectomycorrhizal fungi for later use.

[0032] 3 parts by weight of fermented cedar ba...

Embodiment 3

[0034] Mix 100 parts by weight of 4 mesh cedar bark powder, 200 parts by weight of tung bran, 11 parts by weight of calcium-magnesium phosphate fertilizer, 0.06 parts by weight of slaked lime powder, 0.05 parts by weight of enzyme bacteria, and 0.2 parts by weight of corn flour, mix well, add moisture, and cover The plastic film is piled for 20 days to obtain fermented fir bark powder for use.

[0035] Mix 100 parts by weight of 9-mesh cedar bark powder, 2.5 parts by weight of urea, 0.02 parts by weight of hydrated lime powder, and 0.01 parts by weight of 95% dixone wettable powder, mix well, add water, cover plastic film and pile for 30 days to obtain adsorption Chinese fir bark powder is reserved.

[0036] Mix 10 parts by weight of rice bran, 0.01 parts by weight of boletus edulis and 0.01 parts by weight of boletus edulis, mix well, add water, and cultivate for 15 days to obtain amplified ectomycorrhizal fungi for later use.

[0037] 4 parts by weight of fermented cedar bark powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com