Photostable antimicrobial polypropylene material product and preparation method thereof

An antibacterial polypropylene and antibacterial material technology, applied in the field of light-stable antibacterial polypropylene modified material products and their preparation, can solve problems such as inability to overcome light stability, human health hazards, and difficulty in dispersion, and prevent crystal nucleation. , Guarantee the effect of effective utilization and uniform and dense film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

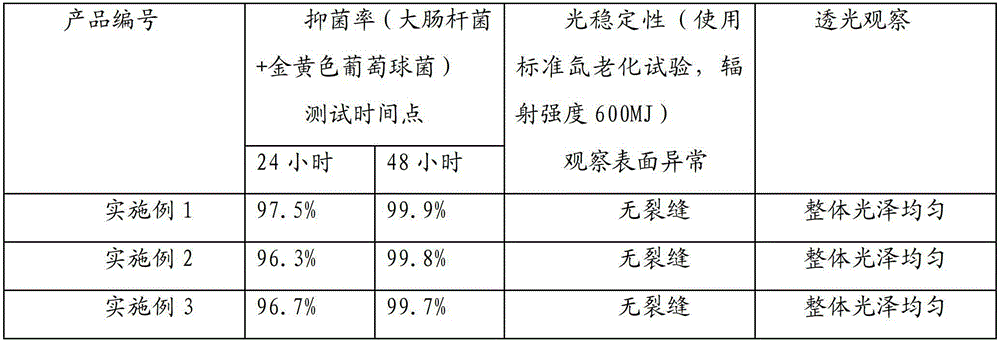

Examples

Embodiment 1

[0027] 85% of PP, 2% of nano-titanium dioxide particles, 3% of nano-silver particles, 6% of ethylene-propylene copolymer, 0.1% of antioxidant BHT and 3.9% of stearic acid by weight by melt blending method Zinc mixed well.

[0028] The above components are melt-mixed by twin-screw extrusion to prepare polypropylene modified material.

[0029] The above materials are injection molded into plates by an injection molding machine, placed overnight under natural conditions, and then the plates are placed in an oxygen-containing gas atmosphere, pure titanium is used as a target material, and the plasma sputtering process is performed using an existing plasma coating machine. In the plasma sputtering process, the radio frequency power is 40w, the bias voltage is 50V, and the sputtering time is 5 minutes.

[0030] After sputtering, the thickness of the titanium dioxide film on the surface of the plate is 100nm.

Embodiment 2

[0032] 87% of PP, 1% of nano-titanium dioxide particles, 1% of nano-silver particles, 6% of α-olefin oligomers, 0.1% of antioxidant 168 and 4.9% of polysilicon were mixed by weight by melt blending method. The ketones are mixed well.

[0033] The above-mentioned components were melt-mixed with twin-rotor continuous mixing equipment to prepare polypropylene modified materials.

[0034] The above materials are blown into containers by a blow molding machine, placed overnight under natural conditions, and then the container is placed in an oxygen-containing gas atmosphere, pure titanium is used as a target, and plasma sputtering is performed using an existing plasma coating machine process, in the plasma sputtering process, the radio frequency power is 100w, the bias voltage is 65V, and the sputtering time is 10 minutes.

[0035] After sputtering, the thickness of the titanium dioxide film on the surface of the plate is 325nm.

Embodiment 3

[0037] 92% of PP, 1% of nano-titanium dioxide particles, 0.5% of nano-silver particles, 4% of ethylene-propylene copolymer, 1% of antioxidant PS802 and 1.5% of white mineral oil were mixed by weight by melt blending method. well mixed.

[0038] The above-mentioned components were melt-mixed with an internal mixer to prepare a polypropylene modified material.

[0039] The above materials are injection molded into pipes with an injection molding machine, placed overnight under natural conditions, and then the pipes are placed in an oxygen-containing gas atmosphere, pure titanium is used as the target material, and the plasma sputtering process is performed using an existing plasma coating machine. In the plasma sputtering process, the radio frequency power is 150w, the bias voltage is 80V, and the sputtering time is 20 minutes.

[0040] After sputtering, the thickness of the titanium dioxide film on the surface of the plate is 500nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com