Processing technology and exclusive welding tool for annular cooler special-shaped beam

A technology for welding tooling and processing technology, which is applied to the processing technology of special-shaped beams of annular coolers and the field of special welding tooling, can solve problems such as difficulty in grasping the fluctuation of result errors and dimensional reliability, difficulty in inspection operations, labor-consuming, time-consuming and low-efficiency, etc. problems, to achieve the effect of convenient assembly and fixation before welding, eliminating unqualified and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

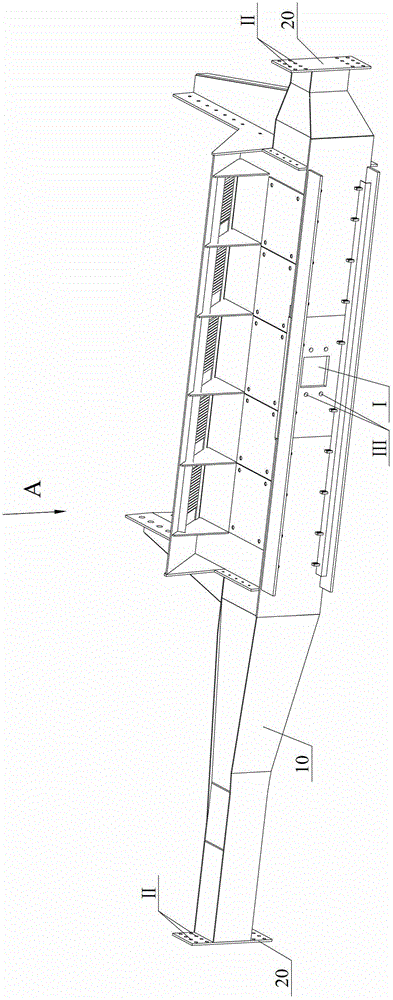

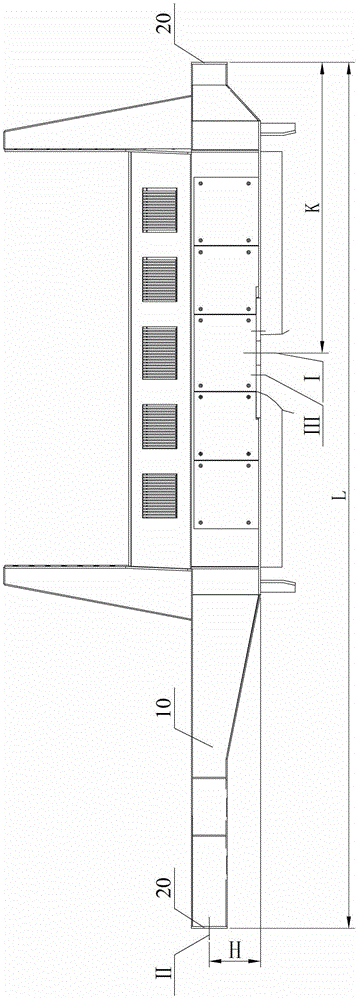

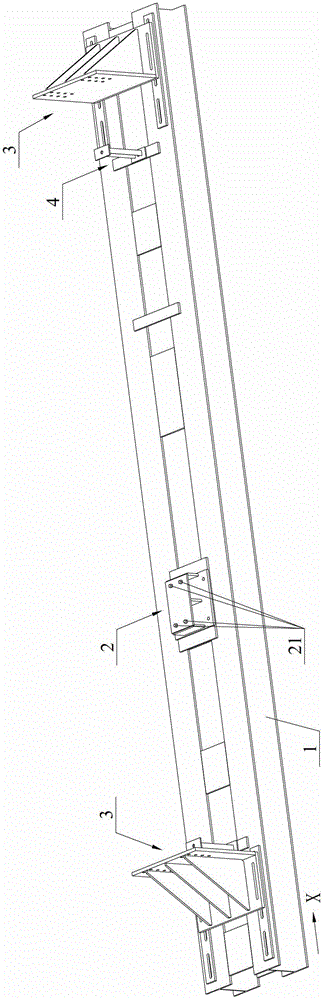

[0037] The core of the present invention is to provide a special welding tool for the processing of special-shaped beams of the ring cooler, which can greatly improve the working efficiency while ensuring the processing accuracy of the special-shaped beams.

[0038] Without loss of generality, this embodiment will be described in detail below in conjunction with the accompanying drawings.

[0039]First of all, it needs to be clarified that the basic functional components of the annular cooler involved in this article and their mutual position and connection relationship are the same as those of the prior art. The annular cooler is roughly divided into high temperature zone, medium temperature zone, low temperature zone and non-cooling mere. During the working process, the trolley and the support beam rotate around the center of the ring cooler in real time at a constant speed, and the middle of the front end of each trolley body is equipped with a hinged seat for connection wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com