Rubber composition for tire insulations and tire using same

一种橡胶组合物、隔离层的技术,应用在充气轮胎的增强层、特殊轮胎、轮胎零部件等方向,能够解决没有考虑到改善滚动阻力特性等问题,达到耐久性优异、滚动阻力特性优异、成本下降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

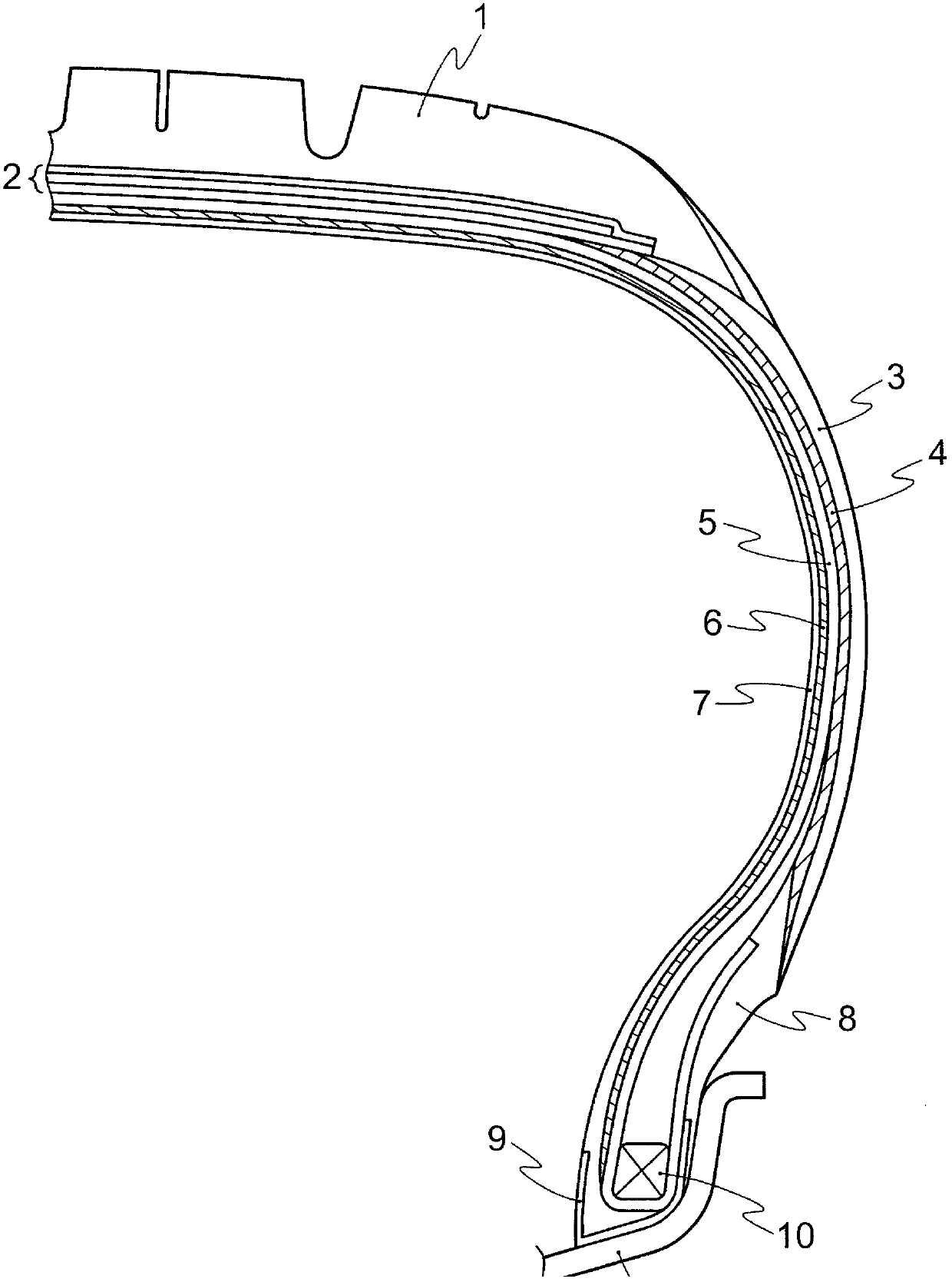

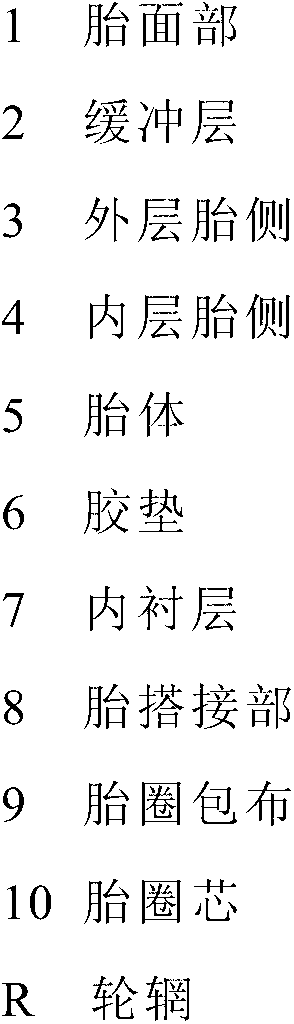

Image

Examples

Embodiment 1~36 and comparative example 1~11

[0132] In the formulations shown in Tables 1 to 4, various chemicals (excluding the alkylphenol-sulfur chloride condensate, insoluble sulfur and vulcanization accelerator TBBS) were kneaded in a Banbury internal mixer to obtain kneaded products. Next, using an open mill, the alkylphenol-sulfur chloride condensate, insoluble sulfur, and vulcanization accelerator TBBS were added to the obtained kneaded product and kneaded to obtain an unvulcanized rubber composition. The obtained unvulcanized rubber compositions were vulcanized under pressure at 170° C. for 12 minutes to prepare vulcanized rubber compositions of Examples 1 to 36 and Comparative Examples 1 to 11, and the following viscoelasticity tests and tensile tests were performed.

[0133] (viscoelasticity test)

[0134] The prepared test piece was cut to a width of 4 mm, a length of 40 mm, and a thickness of 2 mm. Using a viscoelastic spectrophotometer VES (viscoelastic spectrometer VES) manufactured by Iwamoto Seisakusho C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com