Closed ammonia-resistant motor with ammonia-resistant insulation system

An insulation system and closed technology, which is applied in the field of closed ammonia-resistant motors, can solve the problems of unsatisfactory cooling conditions, poor heat dissipation conditions, and no one cares about refrigeration compressors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

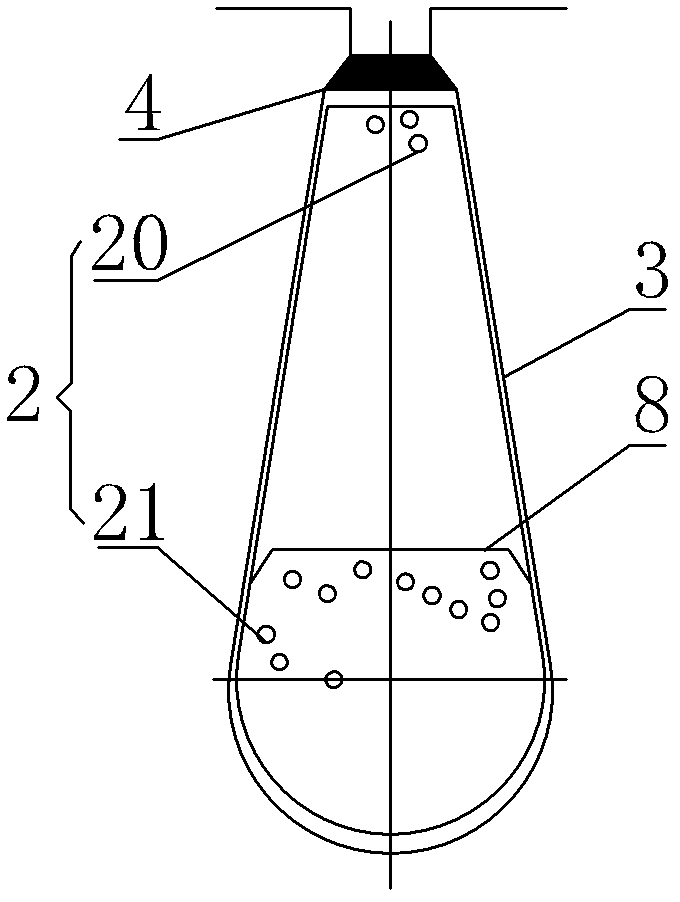

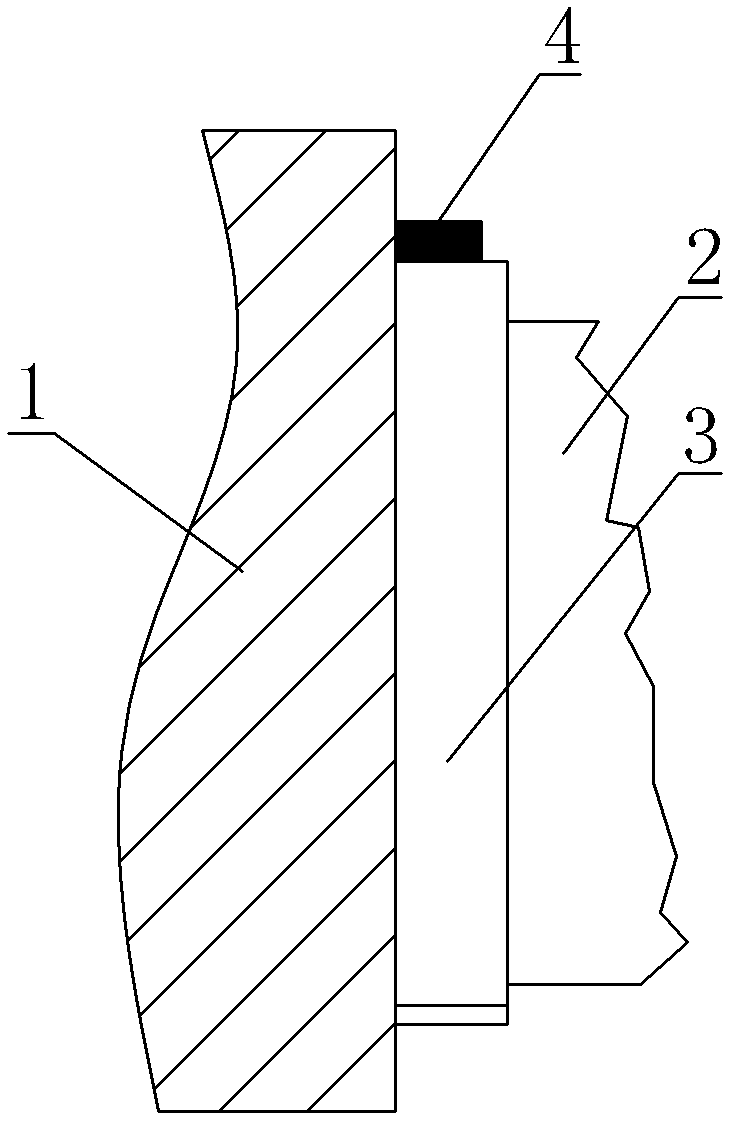

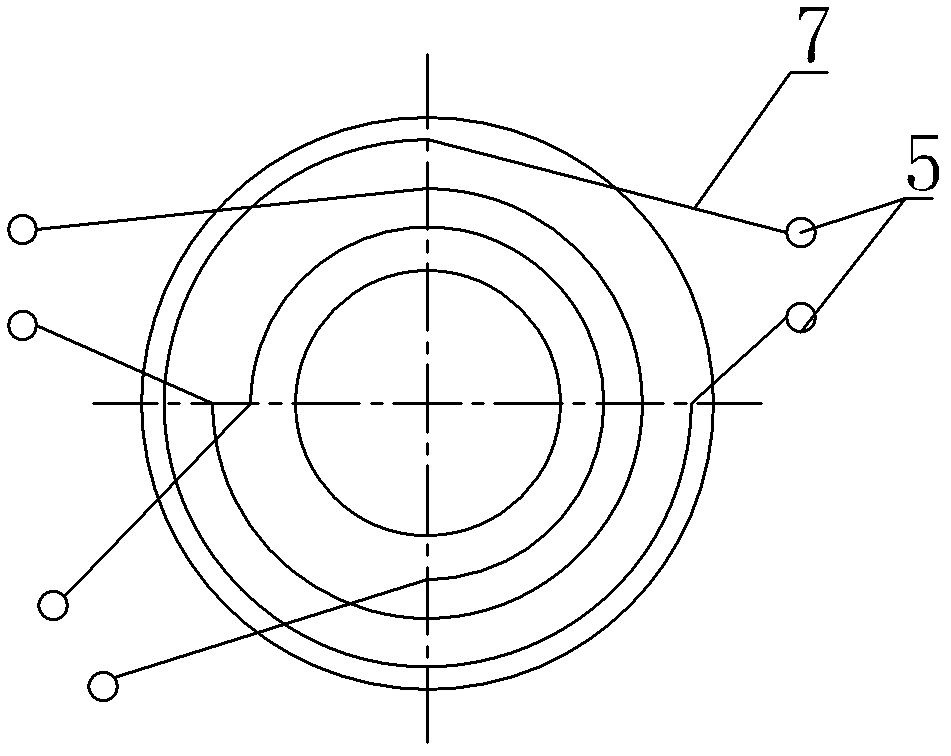

[0031] A closed ammonia-resistant motor using an ammonia-resistant insulation system: the same as the traditional motor, including a stator core 1, a stator winding 2 wound in the stator core slot, a slot insulation 3 for insulating the stator winding 2, and a fixed stator Slot wedge 4 for winding 2. The stator winding 2 has an inter-pole connection lead wire 7, and the end of the inter-pole connection lead wire 7 has a connection terminal 6, and the number of groups of the lead connection terminal 6 corresponds to the number of phases. The stator winding 2 includes an upper layer winding 20 and a lower layer winding 21 , and the upper layer winding 20 and the lower layer winding 21 are separated by an interlayer insulation 8 .

[0032] The conditions and materials for the selection of insulation systems for manufacturing ammonia-resistant refrigeratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com