A kind of aluminum induced crystallization polycrystalline silicon thin film solar cell and preparation method

A polysilicon film and polysilicon technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to crystallize silicon films, low efficiency, low production efficiency and low battery efficiency, and achieve cost savings of raw materials, good application prospects, The effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

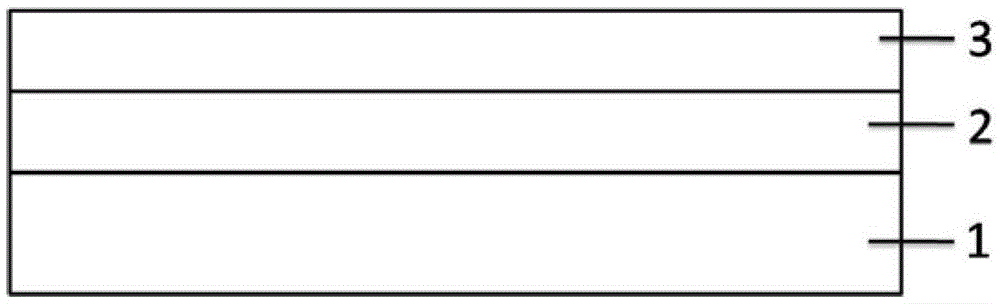

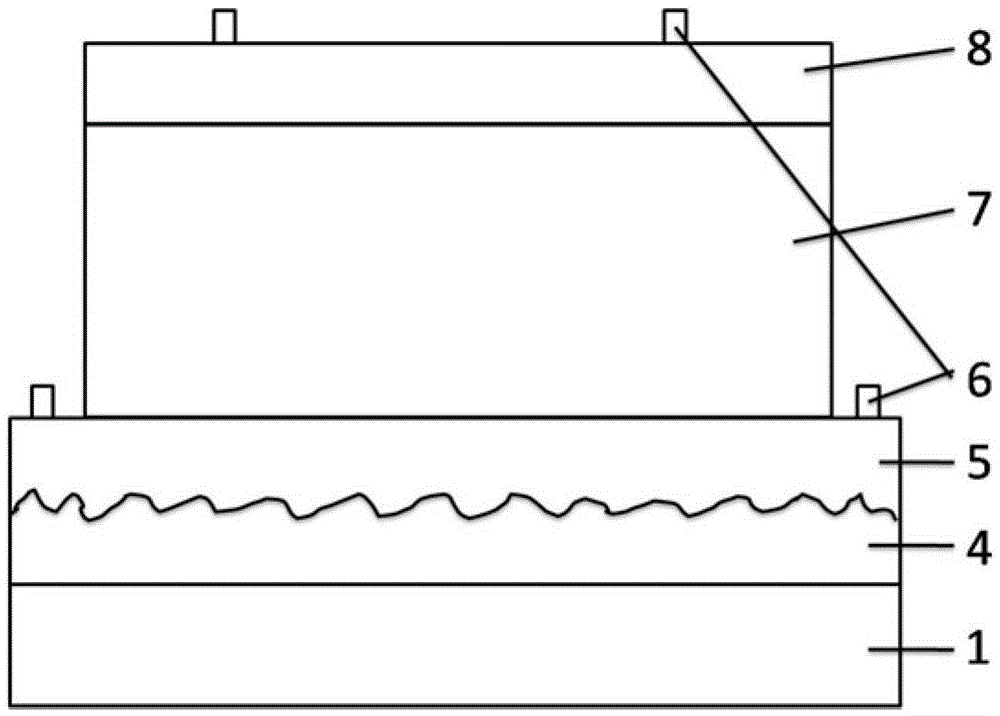

[0026] (1) if figure 1 As shown, a piece of ultra-clear float glass with a size of 150×150×3 mm is selected as the substrate 1 of a polysilicon thin film battery, and an amorphous silicon thin film 2 is grown by PECVD. PECVD process conditions: background vacuum higher than 10 -7 Torr, substrate temperature 150-180°C, pressure 0.36-0.5Torr, RF power 2.5-20W, frequency 13.56MHz, gas SiH 4 The flow rate is 4-10 sccm, and the thickness of the amorphous silicon thin film 2 is 100-150 nm.

[0027] (2) Aluminum thin film 3 is subsequently deposited by magnetron sputtering. Sputtering process conditions: the background vacuum is higher than 10 -7 Torr, the substrate temperature is room temperature, the pressure is 0.005-0.01Torr, the radio frequency power is 100-200W, the frequency is 13.56MHz, the gas Ar flow rate is 10-20sccm, and the thickness of the aluminum film 3 is 100-120nm.

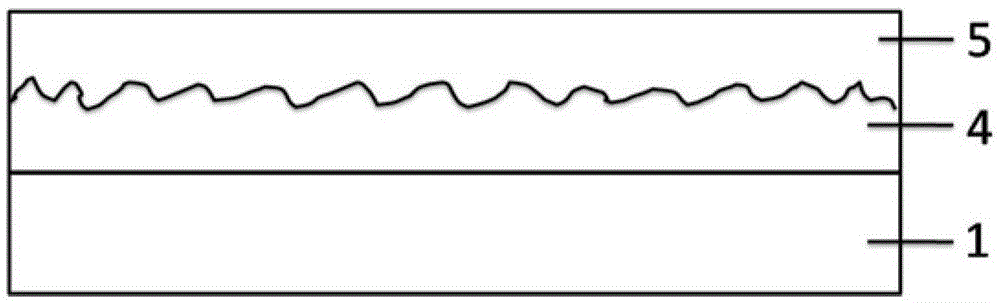

[0028] (3) Anneal the double-layer film in a vacuum annealing furnace, and after annealing at 45...

Embodiment 2

[0031] (1) if figure 1 As shown, a piece of ultra-clear float glass with a size of 150×150×3 mm is selected as the substrate 1 of a polysilicon thin film battery, and an amorphous silicon thin film 2 is grown by PECVD. PECVD process conditions: background vacuum higher than 10 -7 Torr, substrate temperature 150-180°C, pressure 0.36-0.5Torr, RF power 2.5-20W, frequency 13.56MHz, gas SiH 4 The flow rate is 4-10 sccm, and the thickness of the amorphous silicon thin film 2 is 100-150 nm.

[0032] (2) Aluminum thin film 3 is subsequently deposited by magnetron sputtering. Sputtering process conditions: the background vacuum is higher than 10 -7 Torr, the substrate temperature is room temperature, the pressure is 0.005-0.01Torr, the radio frequency power is 100-200W, the frequency is 13.56MHz, the gas Ar flow rate is 10-20sccm, and the thickness of the aluminum film 3 is 100-120nm.

[0033] (3) Anneal the obtained double-layer film in a vacuum annealing furnace. After annealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com