Cutting device

A technology of cutting device and placing groove, applied in sampling device and other directions, can solve the problems of easily changing the shape and position of sediment, slow manual cutting speed, affecting the efficiency of research progress, etc., to achieve no debris pollution, ensure safety, and ensure cutting accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

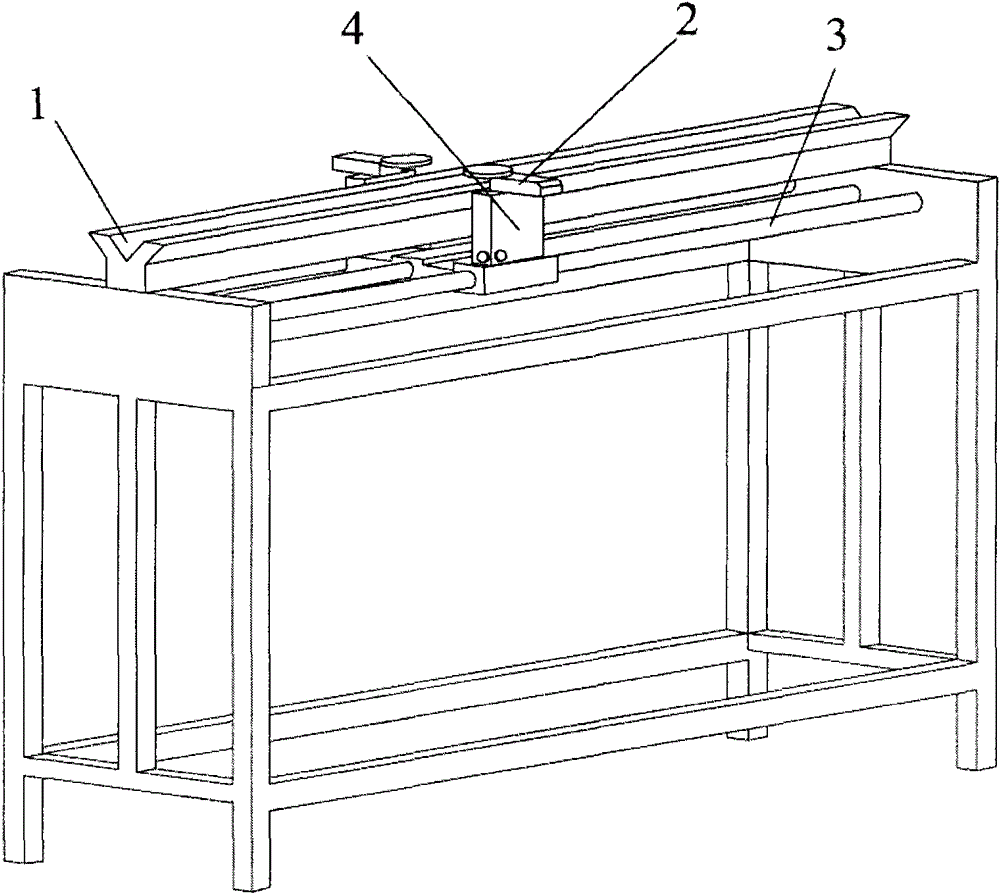

[0017] see figure 1 Describe the cutting device of the present invention, which includes: a bracket provided with a sample placement groove 1; a lead screw 3 that is rotatably supported on the bracket and parallel to the placement groove 1, and the lead screw is driven to rotate by a stepping motor; installed on the lead screw 3 The workbench 4 on the top, wherein a spiral connection is formed between the workbench 4 and the lead screw 3, so that the workbench 4 slides reciprocally along the lead screw 3; the vibration cutting probe 2 installed on the workbench 4 for cutting samples; the control terminal , which is electrically connected with the vibrating cutting probe and the motor driving the lead screw, where the cutting position (that is, the cutting displacement of the cutting probe, including the cutting start point, cutting end point, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com