Middle exhausting gas prevention oil-well pump and oil pumping technology thereof

A kind of oil pump, gas prevention technology, applied in the direction of pump, pump components, variable displacement pump components, etc., can solve the problems of reducing the fullness of the pump cavity, shortening the pump inspection period, and the valve ball opening lag of the oil pump, etc. The effect of environmental pollution, reduction of workover costs, and improvement of oil intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

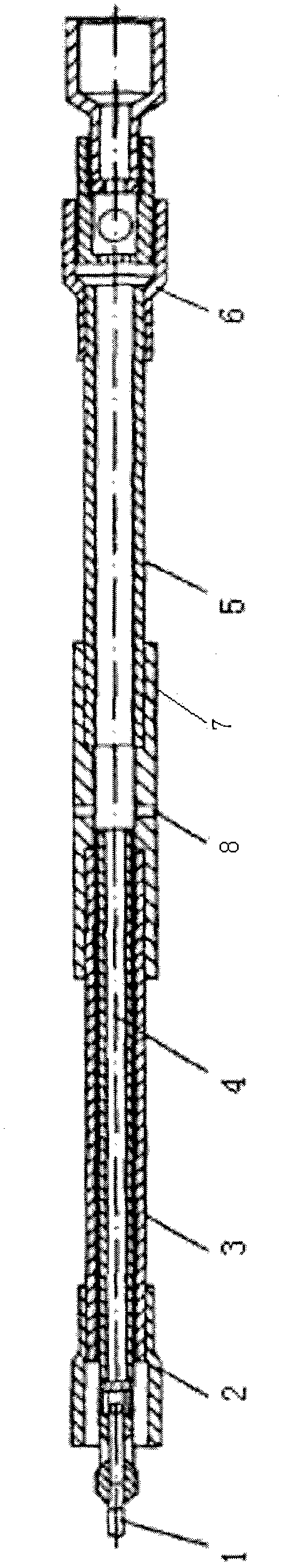

[0029] The middle exhaust air-proof oil well pump that the present invention relates to is as figure 1 As shown, it is mainly composed of an upper pump barrel 3 and a lower pump barrel 5 connected to each other, a plunger 4 arranged inside the upper pump barrel 2, and a plunger connecting rod 1 connected to the plunger 4. The upper pump barrel 3 It is connected in series with the lower pump barrel 5 through the connecting barrel 7, and at least one exhaust hole 8 is arranged on the side wall of the connecting barrel 7.

[0030] The number of the exhaust holes 8 is two, and they are symmetrically arranged on the side wall of the connecting cylinder 7 .

[0031] An upper pump connector 2 is provided on the port of the upper pump barrel 3 away from the lower pump barrel 5 .

[0032] A fixed valve assembly 6 is provided on the end port of the lower pump barrel 5 away from the upper pump barrel 3 .

[0033] The oil pumping process based on the above-mentioned mid-exhaust air-proo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com