Anti-corrosion treatment method for exotic metal structures of maglev steel rails

A technology for anti-corrosion treatment and dissimilar metals, applied in tracks, roads, buildings, etc., can solve the problems of high cost of insulating glue, complicated construction process, colloid aging, etc., and achieve the effect of prolonging service life, simple process and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

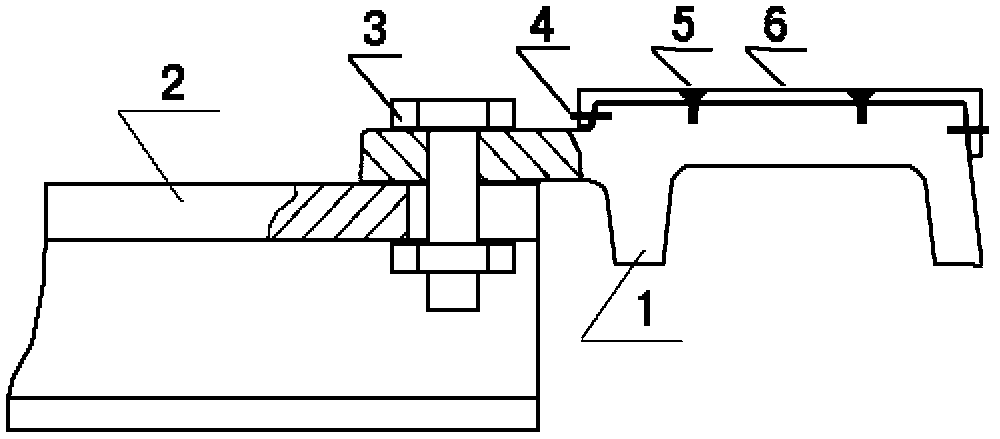

[0035] Embodiment 1. A method for anti-corrosion treatment of a magnetic levitation rail heterogeneous structure, the method comprising the following steps:

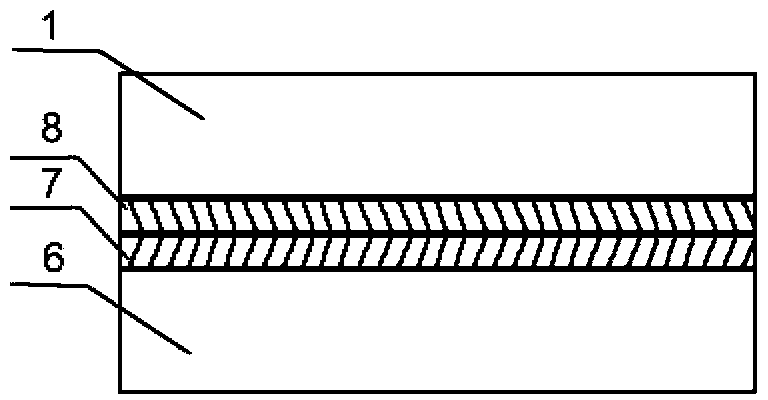

[0036] (1) Clean the surface of the aluminum alloy profile 6 and the surface of the F-shaped steel guide rail 1 to remove the attachments, rust and oxide layer on the surface;

[0037] Use a high-pressure gas spray gun to spray and clean the surface of the aluminum alloy profile 6 to remove the attachments on the surface of the aluminum alloy profile 6. The pressure of the spray gun is controlled at 0.6-0.9MPa; the surface treatment quality of the aluminum alloy profile 6 is dry, dust-free, grease-free, No dirt, no attachments; the compressed air from the high-pressure gas spray gun is dry and clean, and the relative humidity is less than 20%;

[0038] Perform sandblasting treatment on the F-shaped steel guide rail 1 to remove the rust, scale and other attachments on the surface of the F-shaped steel guide rail 1; the su...

Embodiment 2

[0045] A method for anti-corrosion treatment of magnetic levitation rail heterogeneous metal structures, as in Example 1, the difference is that the coating method of the surface of the aluminum alloy profile 6 and the surface of the F-shaped steel guide rail 1 adopts a roller coating method, which is at 5 to 10 ° C, 45 The surface of the aluminum alloy profile 6 and the surface of the F-shaped steel guide rail 1 are coated in a coating environment with a relative humidity of ~60%.

Embodiment 3

[0047] A method for anticorrosion treatment of a magnetic levitation rail dissimilar metal structure, as in Example 1, except that the dry film thickness of the HD4001 aluminum-rich paint coating on the surface of the aluminum alloy profile 6 is controlled at 90-100 μm. After the two coatings, the dry film thickness of the HDX6000 zinc-based coating on the surface of the F-shaped steel guide rail 1 is controlled at 140-160 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com