Method for comprehensively recovering scandium and titanium by leaching red mud with titanium white waste acid

A titanium white waste acid and leaching technology, which is applied in the field of hydrometallurgy, can solve problems that cannot be put into industrial practice, and achieve the effect of cost reduction, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

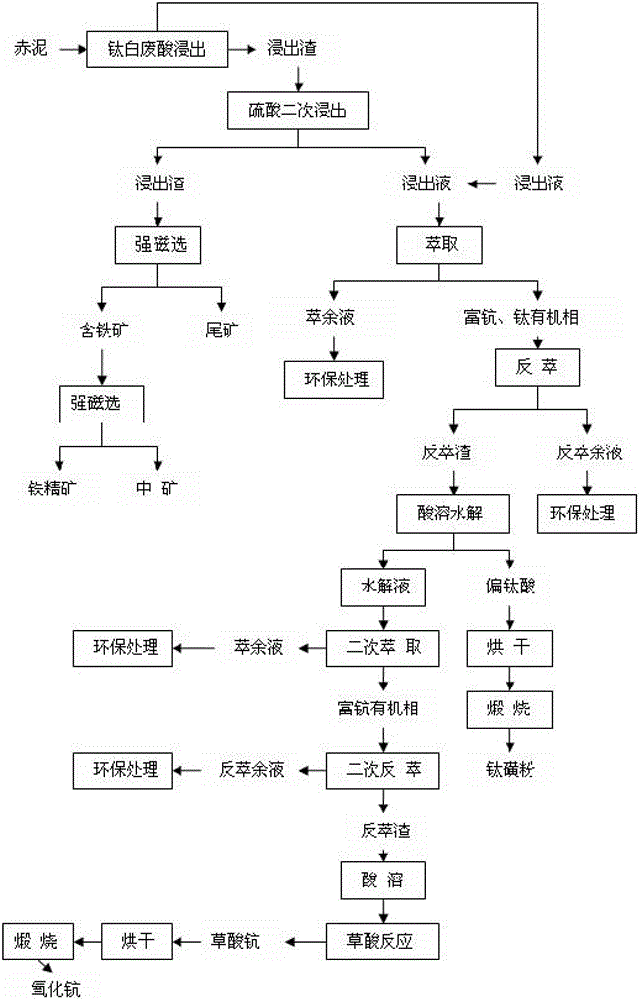

Image

Examples

Embodiment 1

[0029] The method for comprehensively recovering scandium and titanium by leaching red mud with titanium dioxide waste acid according to the present invention comprises the following steps:

[0030] The red mud was obtained from Guangxi Pingguo Aluminum Industry Co., Ltd., and the waste titanium dioxide acid was obtained from Guangxi Jinmao Titanium Industry Co., Ltd.

[0031] Add 60L of titanium white waste acid solution with a concentration of 1.0mol / L into a 100L reaction tank, gradually add 13kg of red mud under stirring, the reaction temperature is 75°C, and the reaction time is 30 minutes. The leached slurry is filtered and washed by a filter press to obtain primary leaching residue and leaching liquid. Sc in leachate 2 o 3 Content 29mg / L, TiO 2 The content is 6.8g / L.

[0032] The leaching residue was leached twice with waste acid with a concentration of 3.5mol / L, and the primary leaching residue was gradually added under stirring, the reaction temperature was contro...

Embodiment 2

[0041] The method for comprehensively recovering scandium and titanium by leaching red mud with titanium dioxide waste acid according to the present invention comprises the following steps:

[0042] The red mud was obtained from Guangxi Pingguo Aluminum Industry Co., Ltd., and the waste titanium dioxide acid was obtained from Guangxi Jinmao Titanium Industry Co., Ltd.

[0043]Add 60L of titanium white waste acid solution with a concentration of 1.5mol / L into a 100L reaction tank, gradually add 13kg of red mud under stirring, the reaction temperature is 50°C, and the reaction time is 60 minutes. The leached slurry is filtered and washed by a filter press to obtain primary leaching residue and leaching liquid. Sc in leachate 2 o 3 Content 35mg / L, TiO 2 The content is 9g / L.

[0044] The leaching residue was leached twice with waste acid with a concentration of 4.0mol / L, and the primary leaching residue was gradually added under stirring, the reaction temperature was controlle...

Embodiment 3

[0053] The method for comprehensively recovering scandium and titanium by leaching red mud with titanium dioxide waste acid according to the present invention comprises the following steps:

[0054] The red mud was obtained from Guangxi Pingguo Aluminum Industry Co., Ltd., and the waste titanium dioxide acid was obtained from Guangxi Jinmao Titanium Industry Co., Ltd.

[0055] Add 60L of titanium white waste acid solution with a concentration of 1.8mol / L into a 100L reaction tank, gradually add 13kg of red mud under stirring, the reaction temperature is 100°C, and the reaction time is 60 minutes. The leached slurry is filtered and washed by a filter press to obtain primary leaching residue and leaching liquid. Sc in leachate 2 o 3 Content 40mg / L, TiO 2 The content is 9g / L.

[0056] The leaching residue was leached twice with waste acid with a concentration of 5.0mol / L, and the primary leaching residue was gradually added under stirring, the reaction temperature was control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com