Hydrocarbon catalytic conversion method for producing low carbon olefin and light aromatic hydrocarbon

A catalytic conversion method and low-carbon olefin technology, applied in the treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of complex process, different catalysts and regeneration devices, etc., to reduce production rate, reduce overall energy consumption, high and low carbon The effect of olefin selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] The examples illustrate the effects of using the method for catalytic conversion of hydrocarbon feedstock provided by the present invention.

[0073] The catalyst MMC-2 was aged at 800° C. with 100% steam for 10 hours, using a medium-sized test device, and the catalyst loading in the composite reactor was 60 kg.

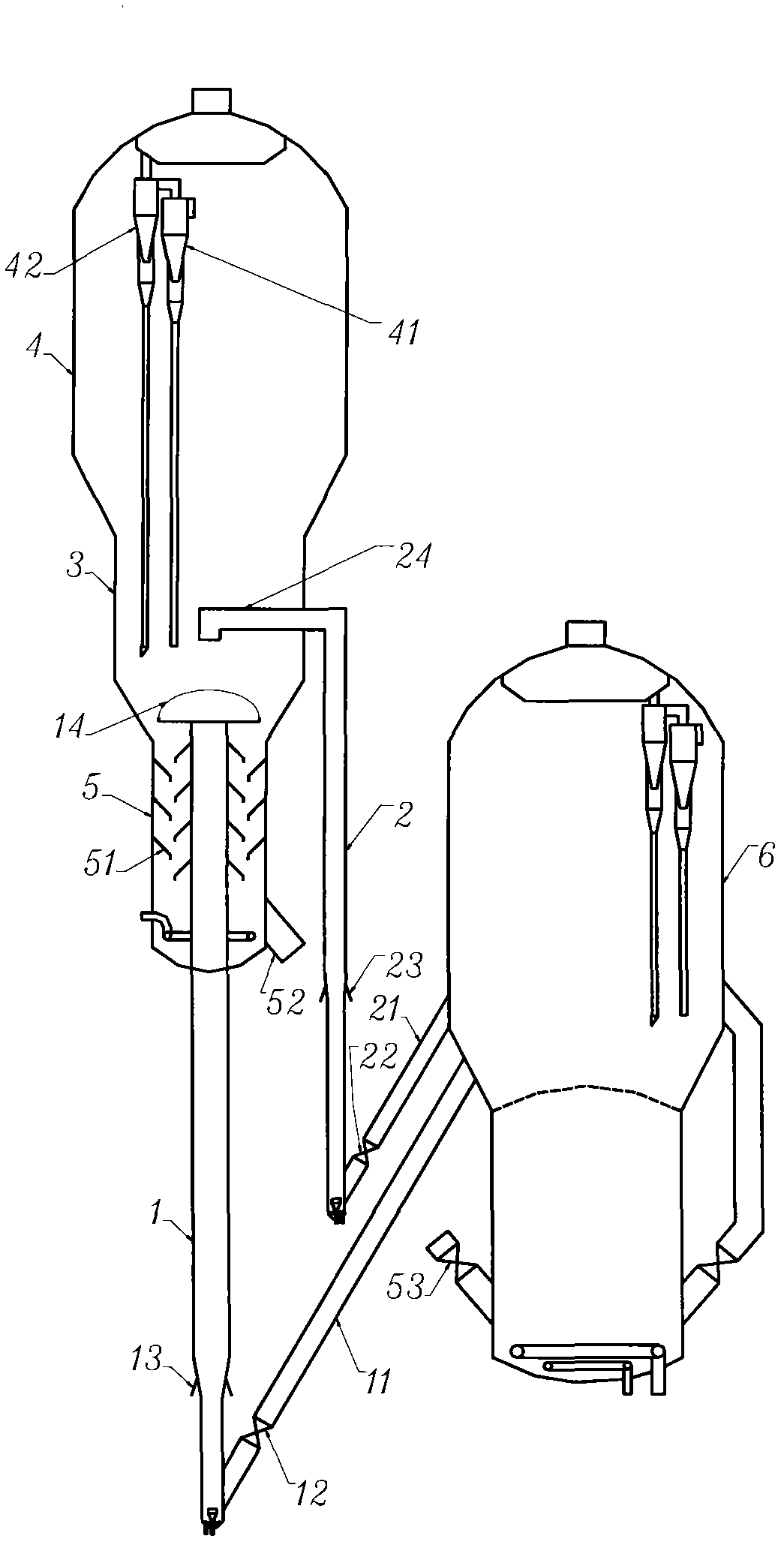

[0074] In the embodiment, the heavy petroleum hydrocarbon raw material enters the riser reactor 1; the catalytic cracking heavy diesel oil of the modifier enters the riser reactor 2 through the nozzle 23.

[0075] The catalyst-to-oil ratio in the examples refers to the weight ratio of catalyst to fresh feed.

[0076] The operating conditions and test results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com