Mixing cap

A technology for bottle caps and mixtures, which is applied to caps with auxiliary devices, caps, containers with multiple items, etc. It can solve the problems of structural damage, easy deterioration, affecting taste and hygiene, etc., and achieves simple and safe use. Structure, convenient production and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

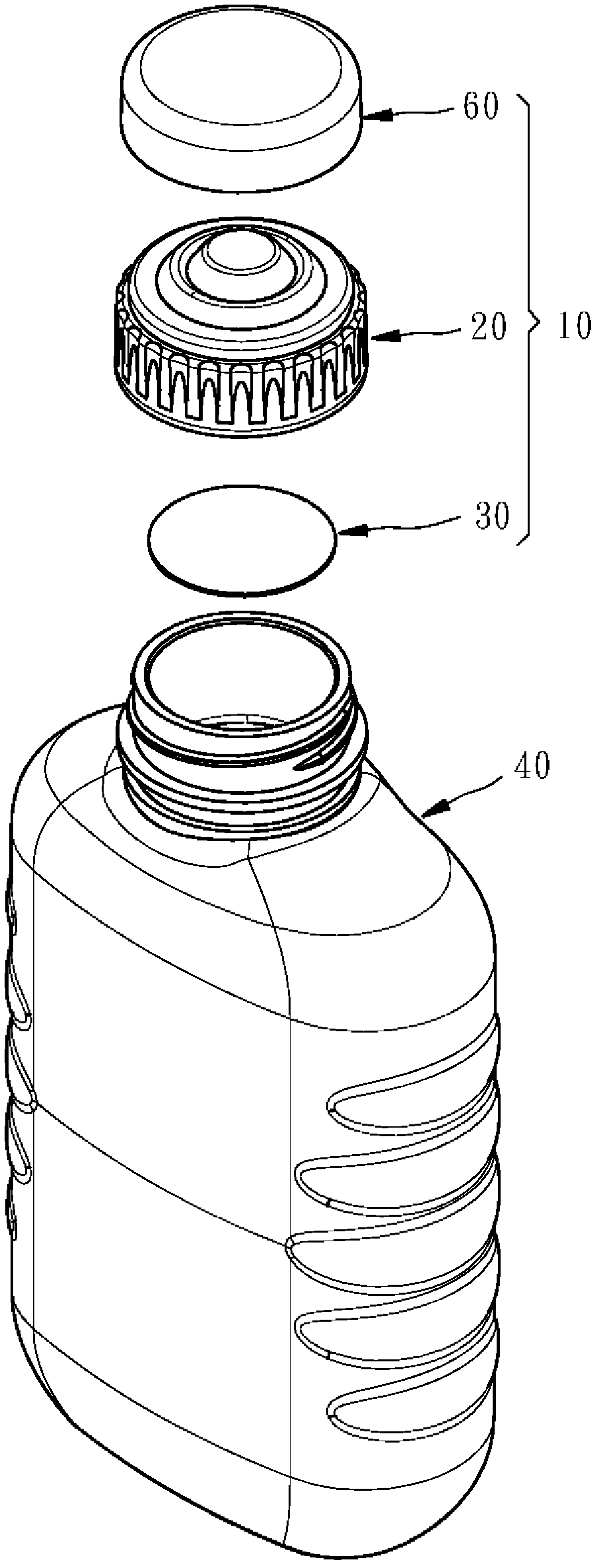

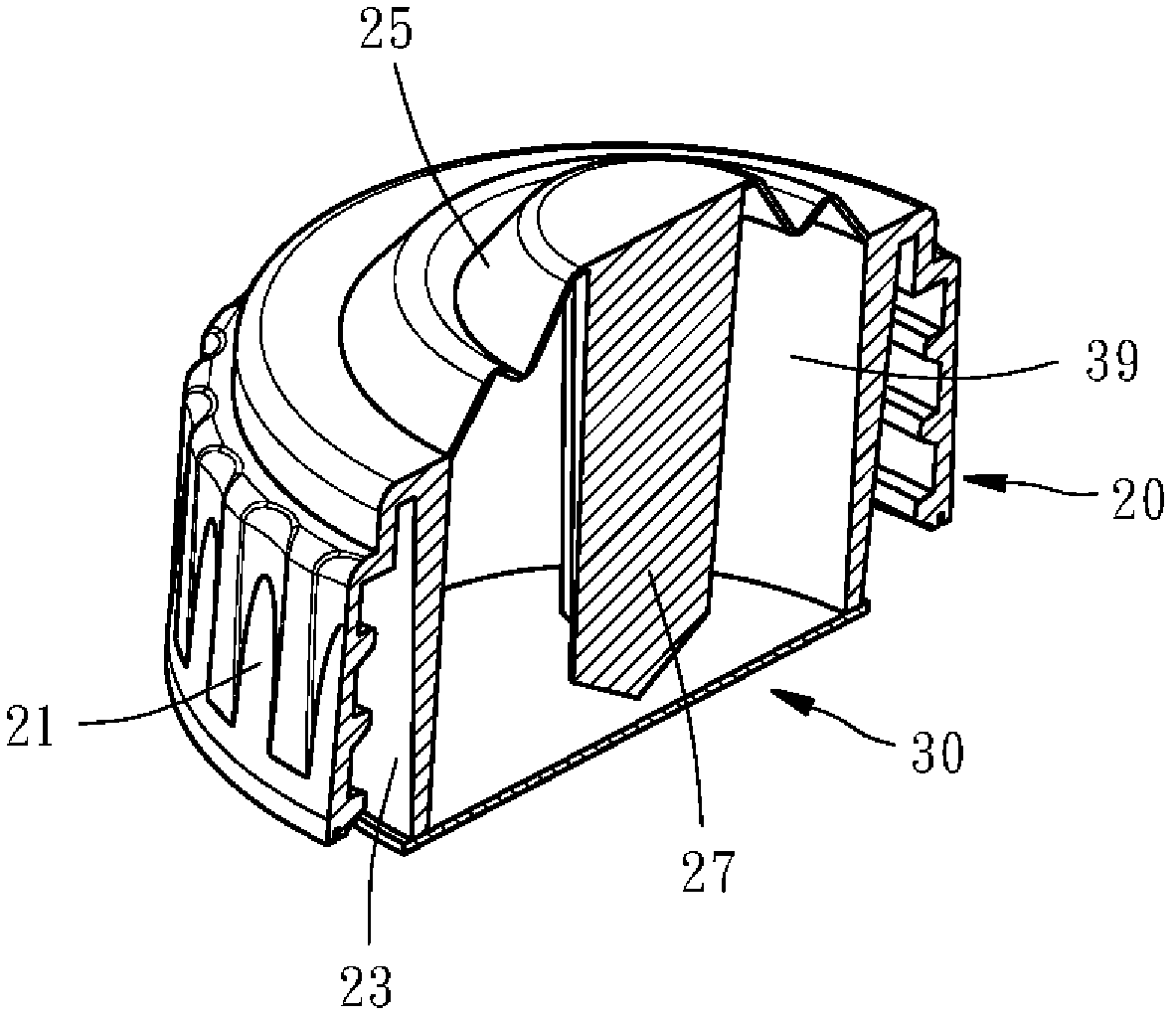

[0032] The bottle cap that can be used for mixing provided by the present invention comprises a cap body, has a bottle joint connected to a bottle mouth of a bottle body, and a mixture tube is connected to the bottle joint and corresponds to the bottle of the bottle body. The mouth, a pressing membrane can be elastically deformed under pressure, and a sealing piece is connected to the mixture container to form an accommodating space for accommodating the materials to be mixed; wherein, the pressing membrane can be elastically deformed under force to directly or Indirect abutment against the closure forms an opening allowing the material to be mixed to enter the bottle.

[0033] Give following preferred embodiment and cooperate accompanying drawing to describe in detail as follows:

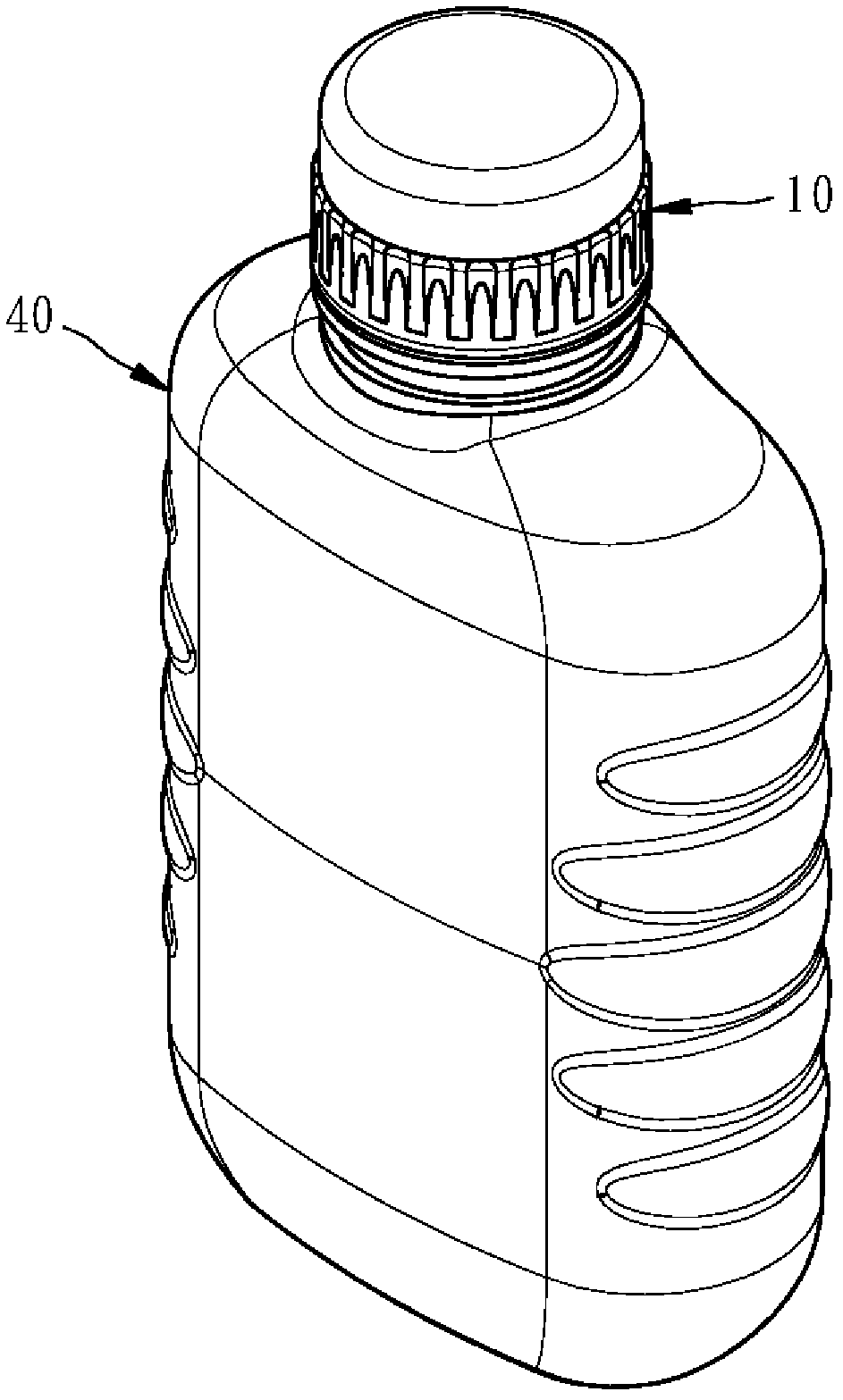

[0034] Such as Figure 1 to Figure 7 As shown, a kind of bottle cap 10 that can be used for mixing provided by a preferred embodiment of the present invention can be installed to a bottle body 40,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com