Automatic material replacing and receiving crusher

A pulverizer and automatic technology, applied in grain processing and other directions, can solve the problems of inability to adapt to the scale and requirements of modern industries, high production costs, and unfavorable economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

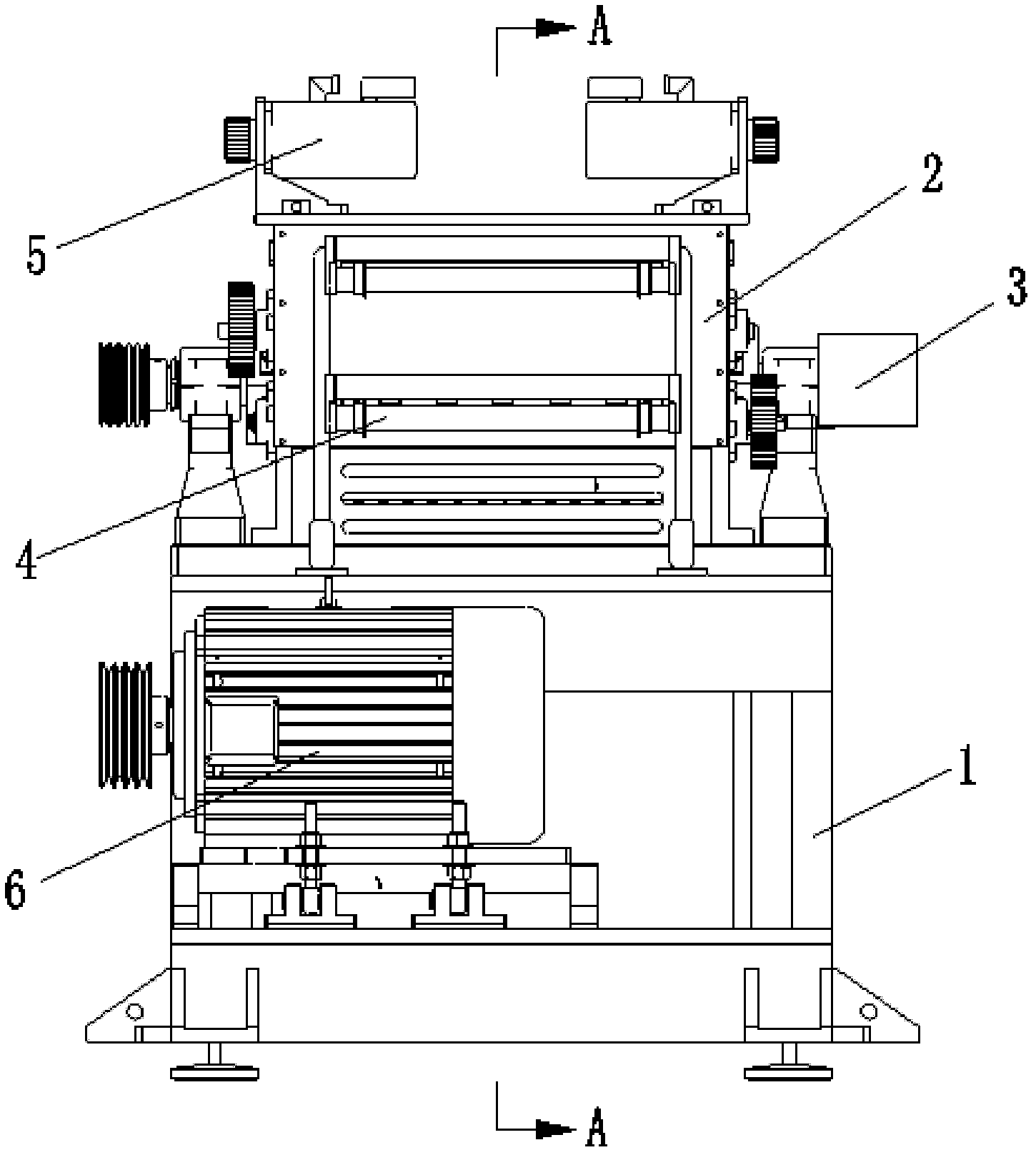

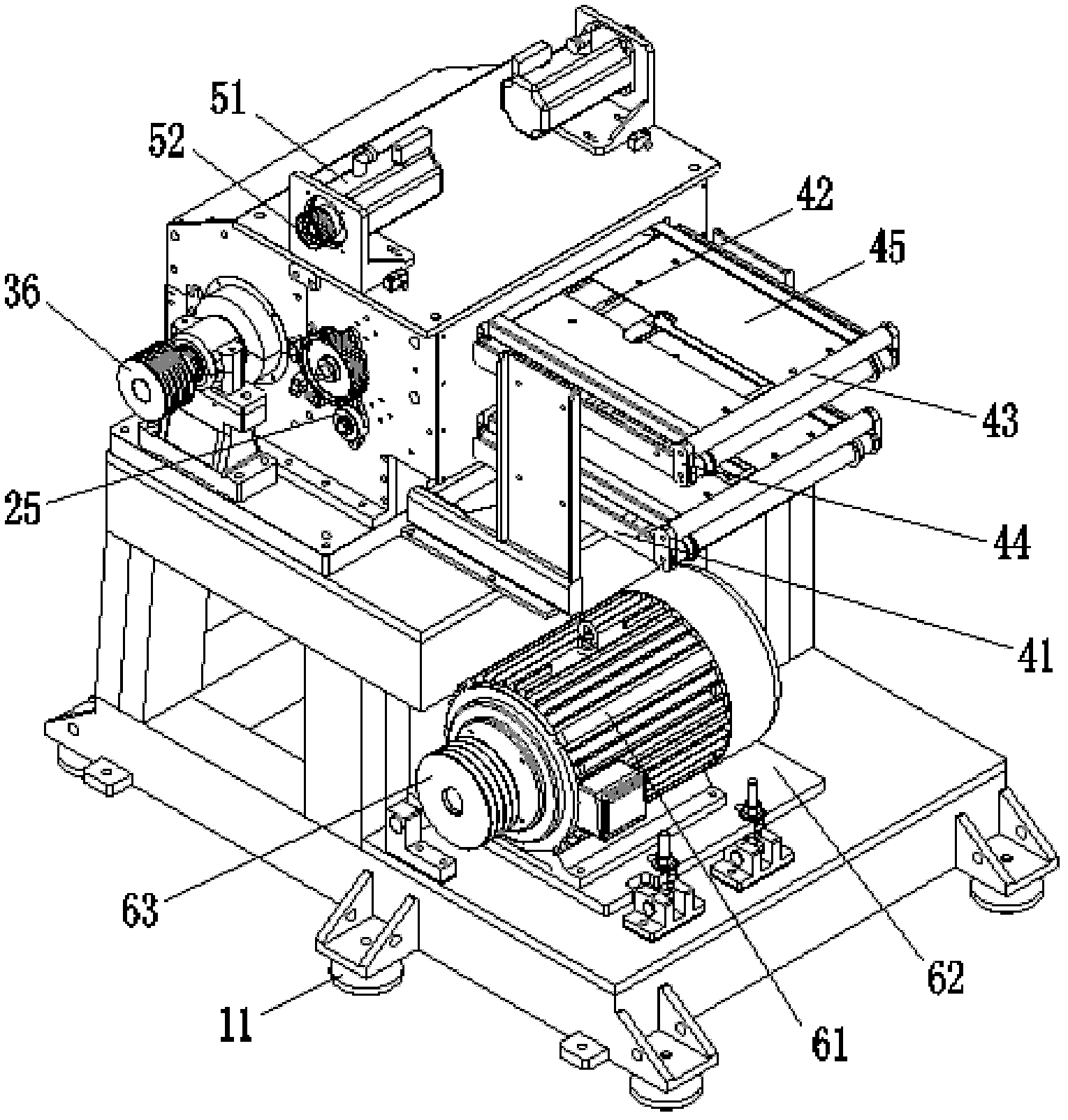

[0027] See Figure 1 to Figure 4 , This embodiment includes a frame 1, a machine head 2, a crushing roller 3, a material guide frame 4, a servo feeding mechanism 5 and a motor driving mechanism 6.

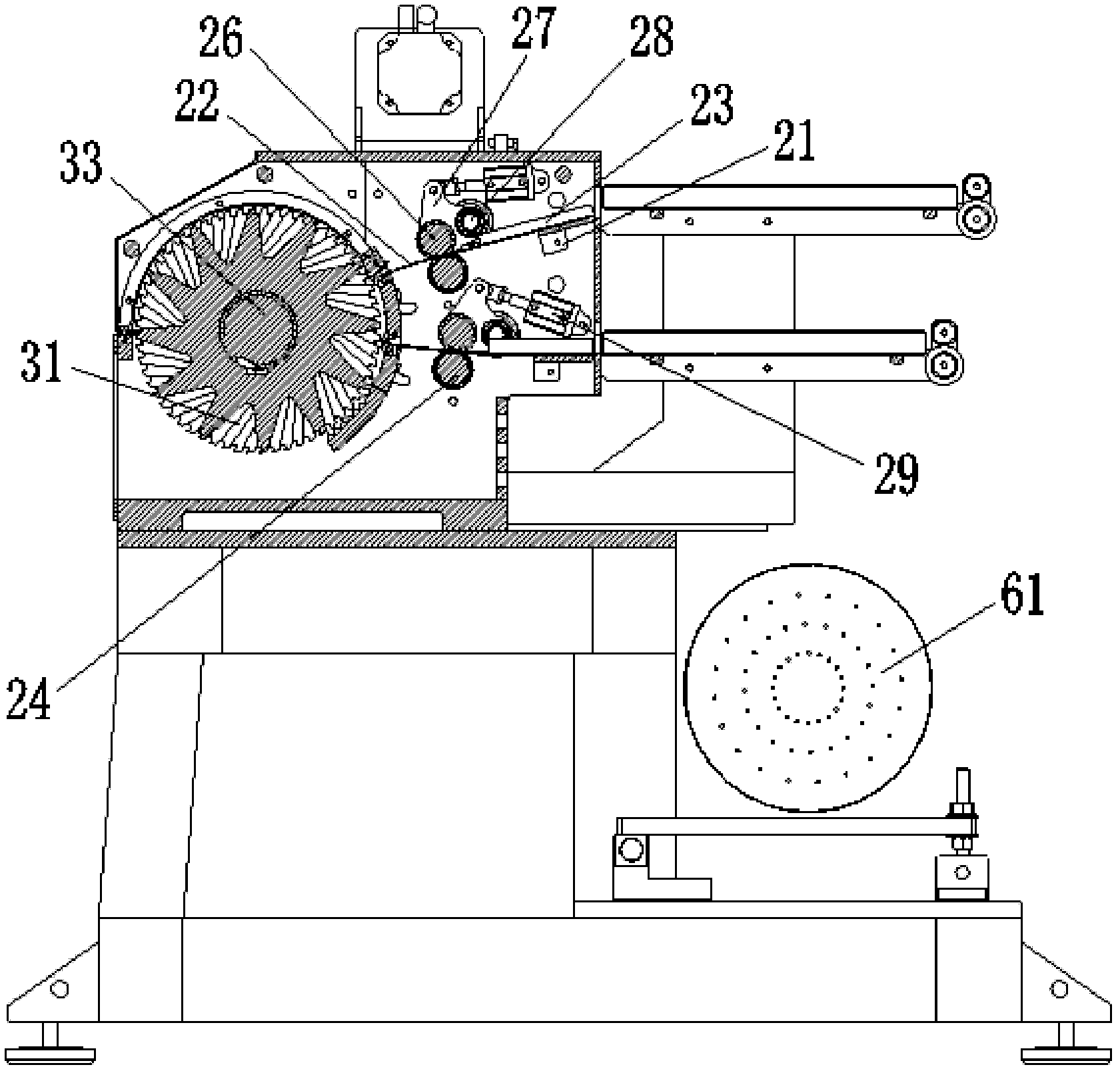

[0028] The frame 1 is provided with two floors with different heights on the left and right, the machine head 2 is installed on the upper layer of the frame 1, and the motor drive mechanism 6 is installed on the lower layer of the frame 1; In the material cavity; the material guide frame 4 is set close to the feeding port of the machine head 2; the servo feeding mechanism 5 is set on the top of the machine head 2, and drives the feeding device in the machine head 2; the motor drive mechanism 6 drives the crushing roller 3 turn. The bottom of the frame 1 is provided with a shock-absorbing pad 11 .

[0029] The machine head 2 is provided with upper and lower feed ports, and a material guide frame 4 is provided on the outside of each feed port; There is a feeding device between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com