Preparation method of silicon-aluminum iron carbonyl composite catalysts with utilization of iron-bearing waste

A composite catalyst, silico-alumina hydroxyl technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of small pH range, iron sludge catalyst recovery Low utilization rate, low utilization rate and other problems, to achieve the effect of wide pH application range, pH applicable range can be recycled and reused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for preparing silicon-aluminum-hydroxy-iron composite catalysts by using iron-containing waste, weighing 1.0g of grinding wheel gray iron filings in a 250mL polytetrafluoroethylene beaker, adding 100mL of 1.0mol / L nitric acid solution, and placing it in a constant temperature shaking box , shake at 55°C for 2h; then adjust the pH to 12 with 2.5mol / L sodium hydroxide solution, continue to shake at 55°C for 30min, then stop shaking, and age at 55°C for 2d. The solid was separated by centrifugation, washed with distilled water until neutral, and then dried at 90°C to obtain the product, which was ground for later use.

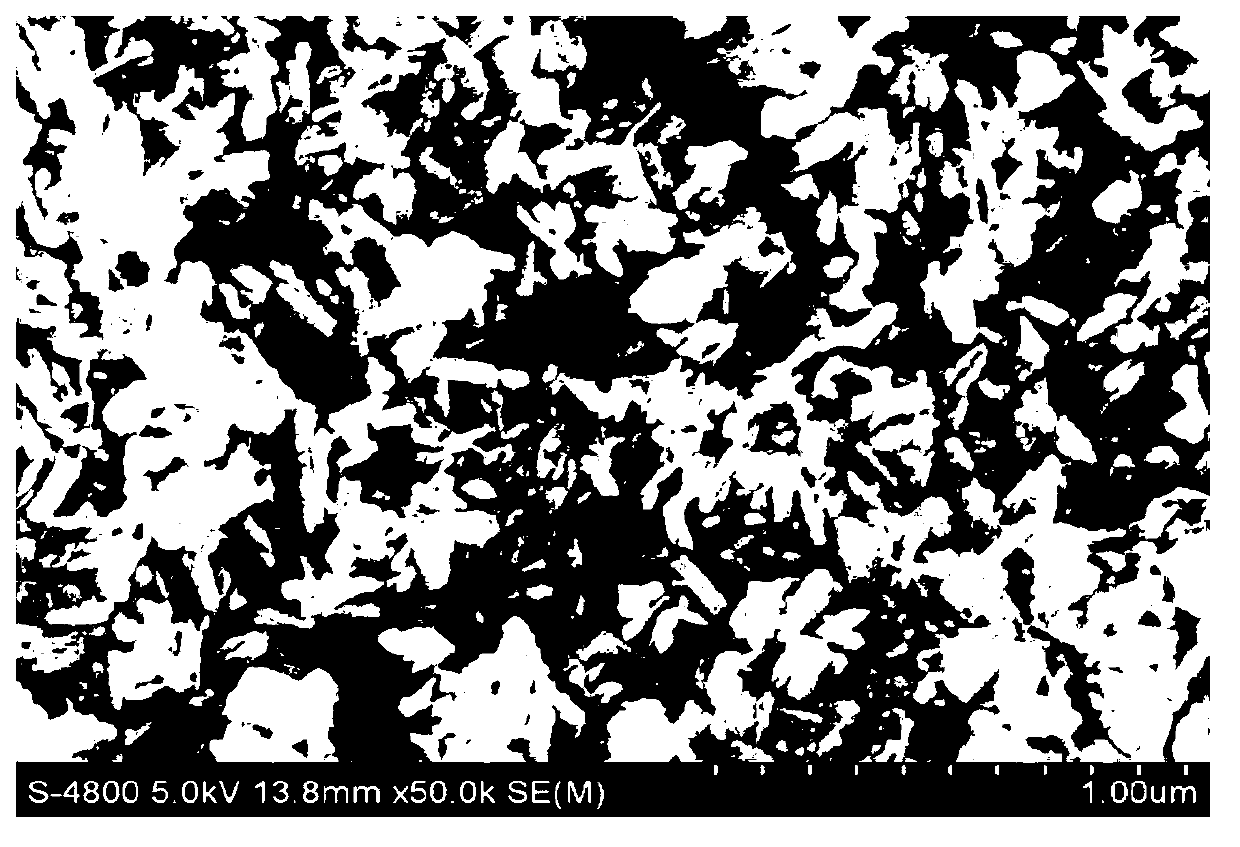

[0020] Weigh 10.1 g of analytical grade reagent ferric nitrate, and prepare hydroxy iron according to the above method. By scanning electron microscopy analysis of FeOOH prepared from two different iron sources, the differences in crystal form and morphology were investigated, such as figure 1 and 2 shown. It can be seen that under the same prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com