Plant empty capsule and preparation method thereof

A plant hollow capsule and glue technology, which is applied in the directions of capsule delivery, food science, pharmaceutical formulation, etc., can solve the problems of gelatin capsule stability greatly affected by temperature, hardening and brittleness, drug leakage, etc., to improve the storage of drugs. , the effect of increasing the breaking strength and reducing the pinhole phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

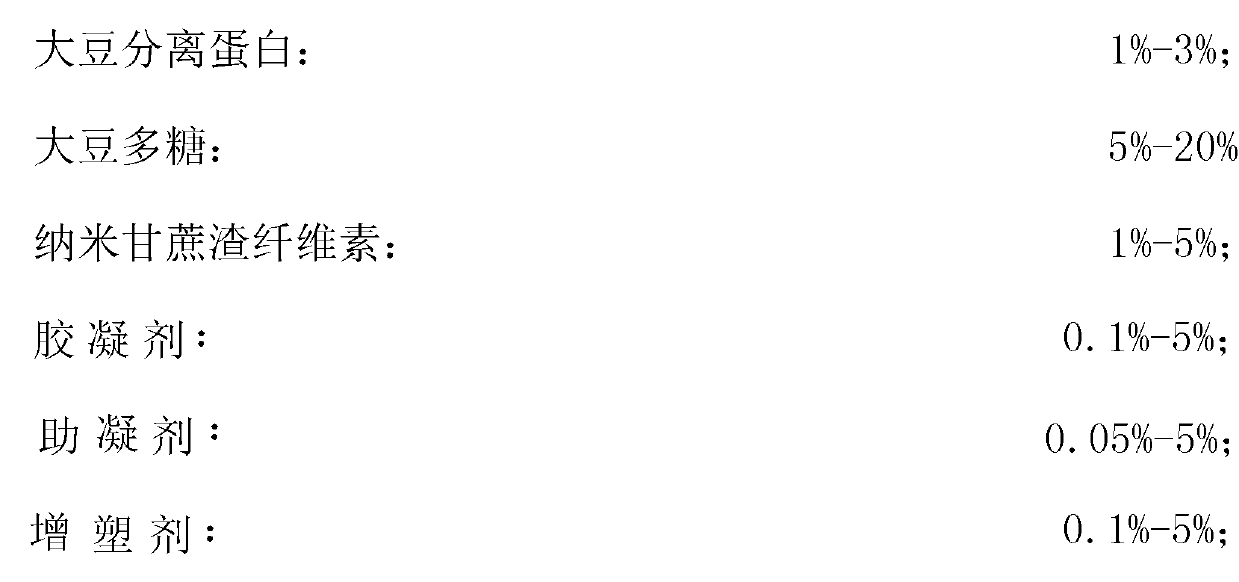

[0024] A new nanocomposite plant capsule formula with soybean protein isolate, soybean polysaccharide and nano-bagasse cellulose as main raw materials:

[0025] components

[0026] Weigh a certain amount of soybean protein isolate, soybean polysaccharide and nano-bagasse cellulose with a weight ratio of 3:10:3, add a certain amount of glycerin as a plasticizer, dissolve with an appropriate amount of deionized water, heat and stir to obtain a glue A, weigh a certain amount of sodium alginate and calcium chloride, stir and dissolve to obtain glue B, pour glue B into glue A, heat up to 75°C and expand for 30 minutes, cool down to 40°C after the mixed glue is uniform, Decompression and defoaming for 7 hours, using the traditional film-dipping technology, the new plant hollow capsules were prepared through film-dipping, drying, shelling, cutting, etc.

Embodiment 2

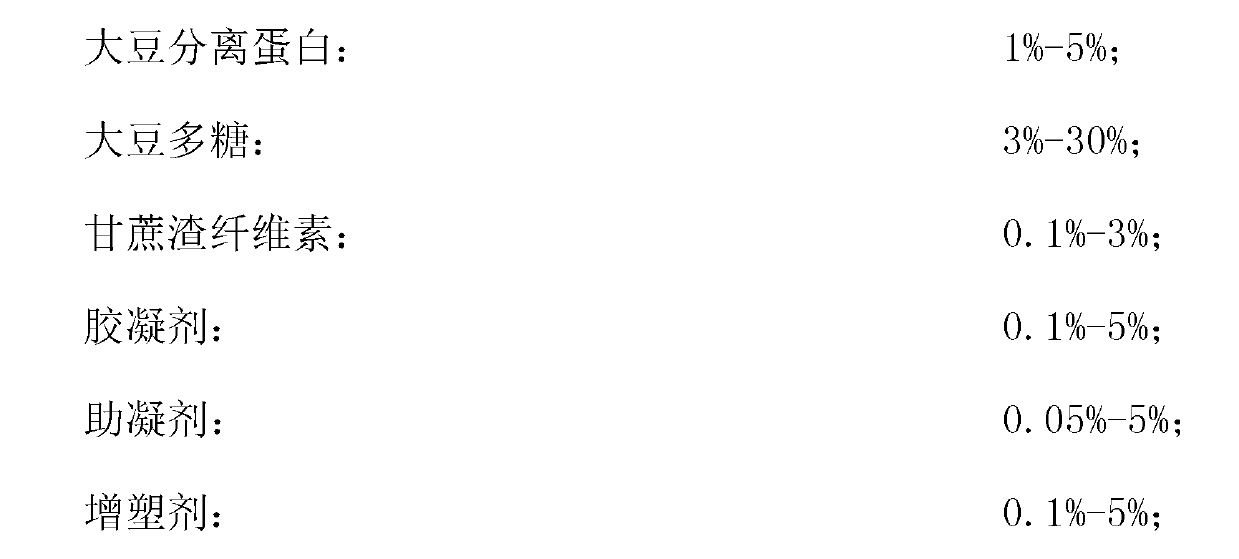

[0028] A new nanocomposite plant capsule formula with soybean protein isolate, soybean polysaccharide and nano-bagasse cellulose as main raw materials:

[0029] components

[0030] Weigh a certain amount of soybean protein isolate, soybean polysaccharide and nano-bagasse cellulose with a weight ratio of 1:5:1, add a certain amount of glycerin, dissolve with an appropriate amount of deionized water, heat and stir to obtain glue A, and Weigh a certain amount of carrageenan and potassium citrate, stir and dissolve to obtain glue B, pour glue B into glue A, heat up to 80°C and puff for 50 minutes, cool down to 50°C after the mixed glue is uniform, and defoam under reduced pressure 8h, using the traditional film-dipping technique, a new type of plant hollow capsule was prepared through film-dipping, drying, shelling, cutting, etc.

Embodiment 3

[0032] A new nanocomposite plant capsule formula with soybean protein isolate, soybean polysaccharide and nano-bagasse cellulose as main raw materials:

[0033] components

[0034] Weigh a certain amount of soybean protein isolate, soybean polysaccharide and nano-bagasse cellulose with a weight ratio of 2:14:5, add a certain amount of polyethylene glycol, dissolve with an appropriate amount of deionized water, heat and stir to obtain a glue A, take a certain amount of agar and potassium chloride and stir to dissolve to obtain glue B, pour glue B into glue A, heat up to 90°C and expand for 45min, cool to 50°C after the mixed glue is uniform, and depressurize Defoaming for 8 hours, using the traditional film-dipping technology, the new plant hollow capsules were prepared through film-dipping, drying, shelling, cutting, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com