An outdoor UHV test expansion connection line

A connecting wire and ultra-high voltage technology, which is applied in the field of outdoor ultra-high voltage test expanding connecting wire, can solve the problems of high manpower and material resources, low reliability, heavy weight, etc., to suppress corona, reduce test costs, and reduce weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

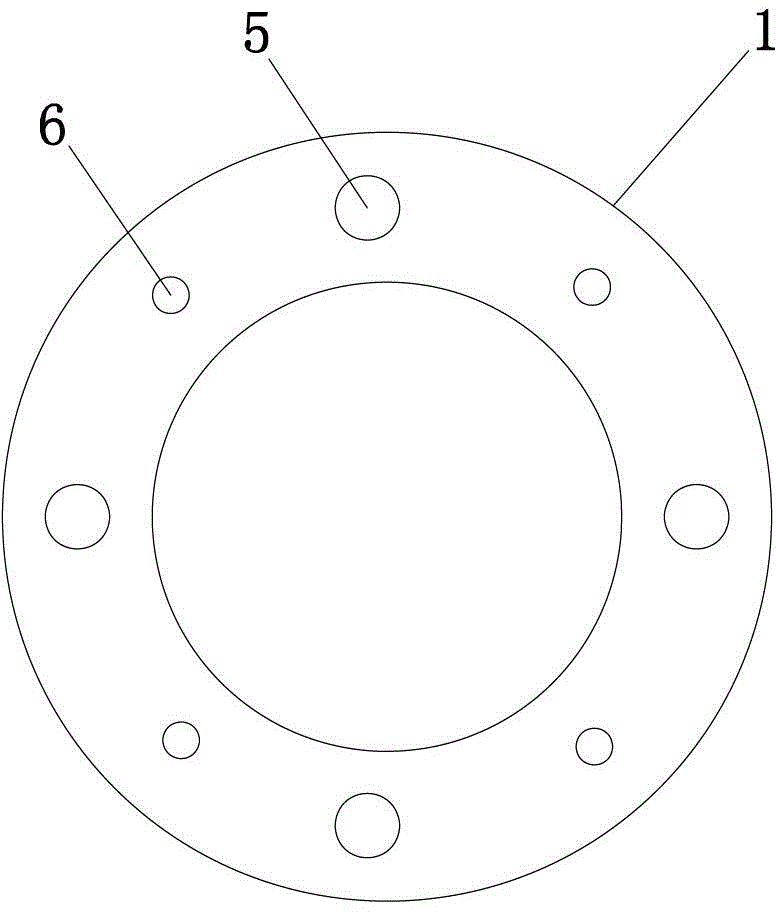

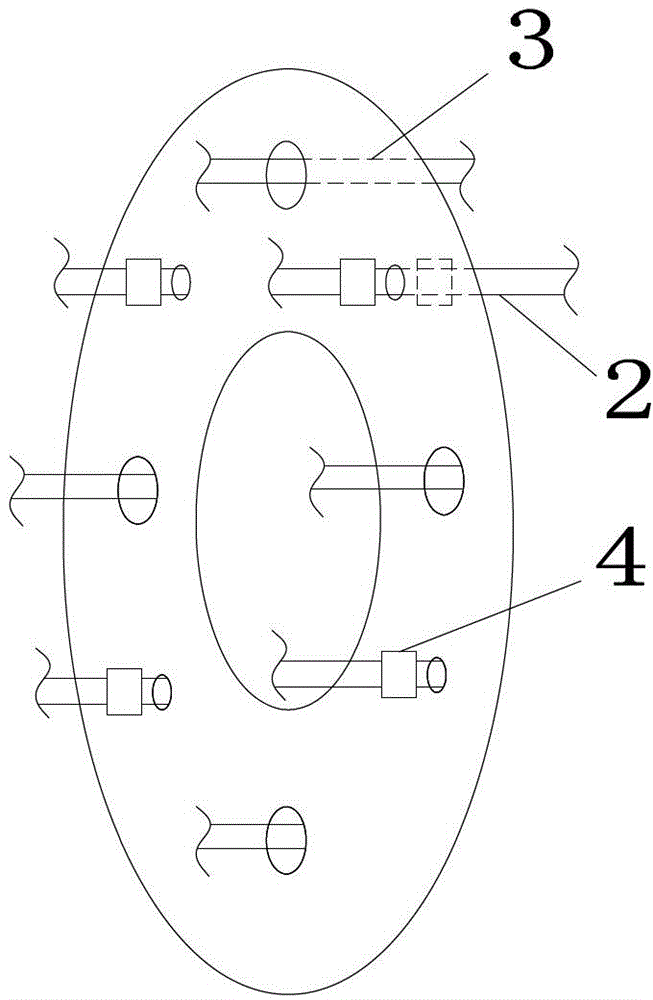

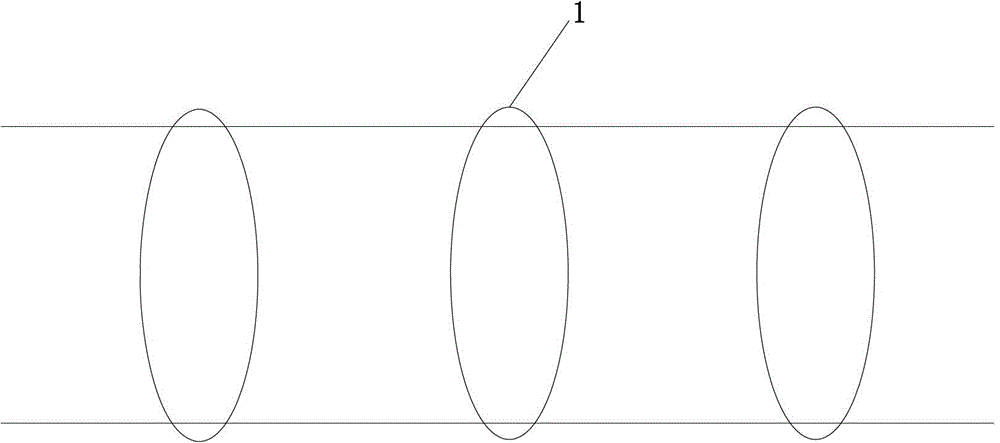

[0020] Such as figure 1 and figure 2 As shown, an outdoor UHV test expansion connection line, including spacer 1, stressed steel wire 2, conductive braided wire 3 and limit device 4, due to the test related to the test platform, generally speaking, the normal current does not exceed 10A, so it is not necessary to use a hard wire with a large cross-section for engineering, with a cross-sectional area of 20mm 2 The copper wire can meet the flow demand. When the voltage level reaches 1100kV, use a single 20mm 2 The surface field strength of the copper wire will exceed the corona inception voltage. On the one hand, it will cause a large corona noise, and on the other hand, it will bring adverse effects such as radio interference to other equipment. Therefore, it is considered to use split wires to reduce the surface fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com