Method for producing ethylbenzene by performing vapor phase alkylation on ethanol and benzene

A technology of alkylation and ethanol, applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc., can solve the problem of low ethylbenzene selectivity and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 50g SiAl Molar Ratio SiO 2 / Al 2 o 3 =200, the grain size is 150 nanometers, and the diameter is the binderless ZSM-5 molecular sieve catalyst of Φ1.8 millimeters, exchanged three times with 0.5 liters of hydrochloric acid of 0.1 mol / liter at 85 ° C, washed with deionized water until no chloride radicals, Dry at 110°C, and then bake at 580°C for 4 hours before use.

[0022] 20 grams of the above catalyst and 40 milliliters of 0.4 mol / liter lanthanum nitrate aqueous solution were impregnated at room temperature for 4 hours, then dried at 110 ° C for 10 hours, and then calcined at 550 ° C for 4 hours, the obtained catalyst contained La 2 o 3 2.0% by weight.

[0023] Treat the above catalyst with water vapor at 580°C under normal pressure for 3 hours, and then treat it with 1.5 mol / liter phosphoric acid solution at 50°C for 5 hours. hours, the finished catalyst was obtained.

Embodiment 2~10

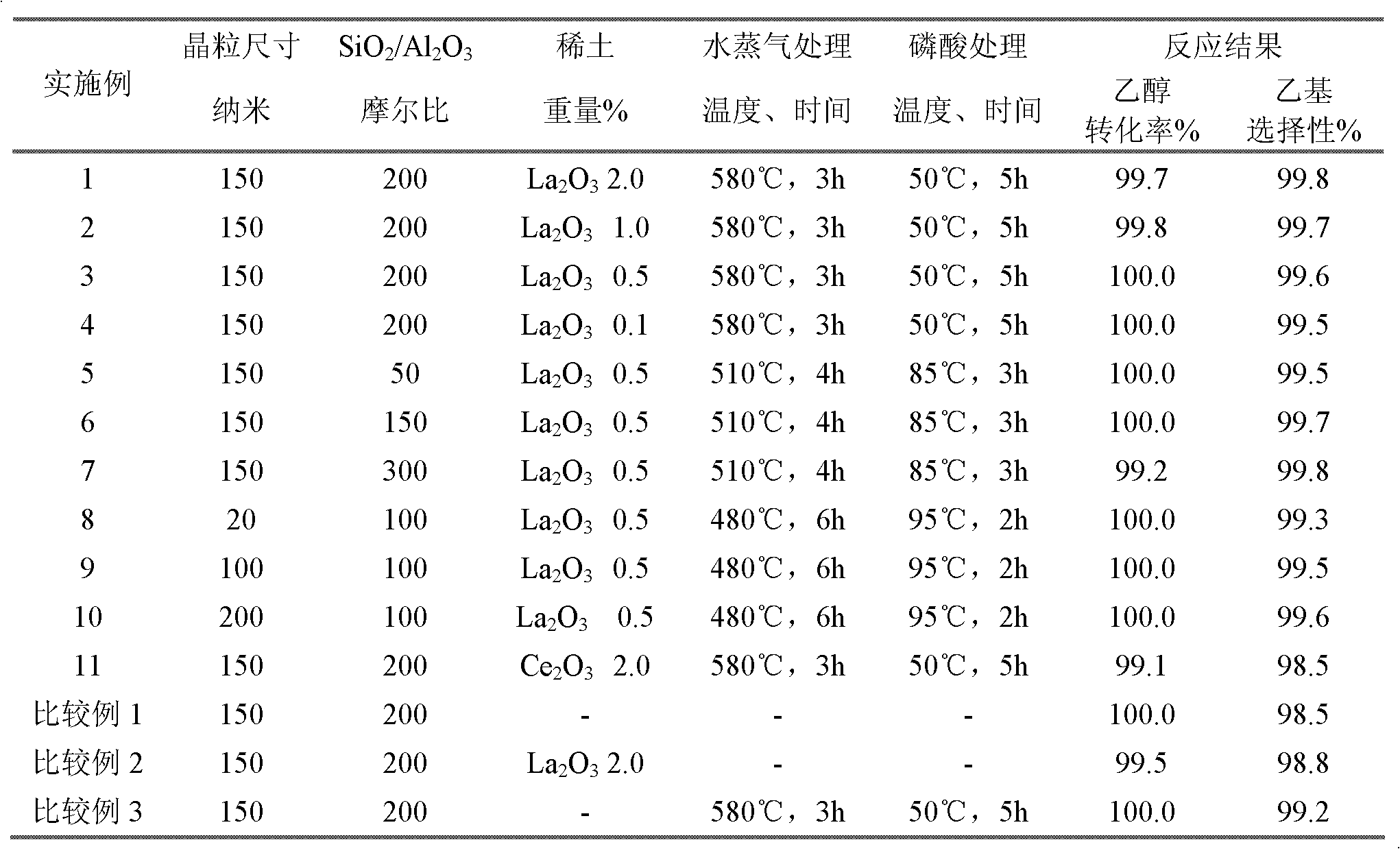

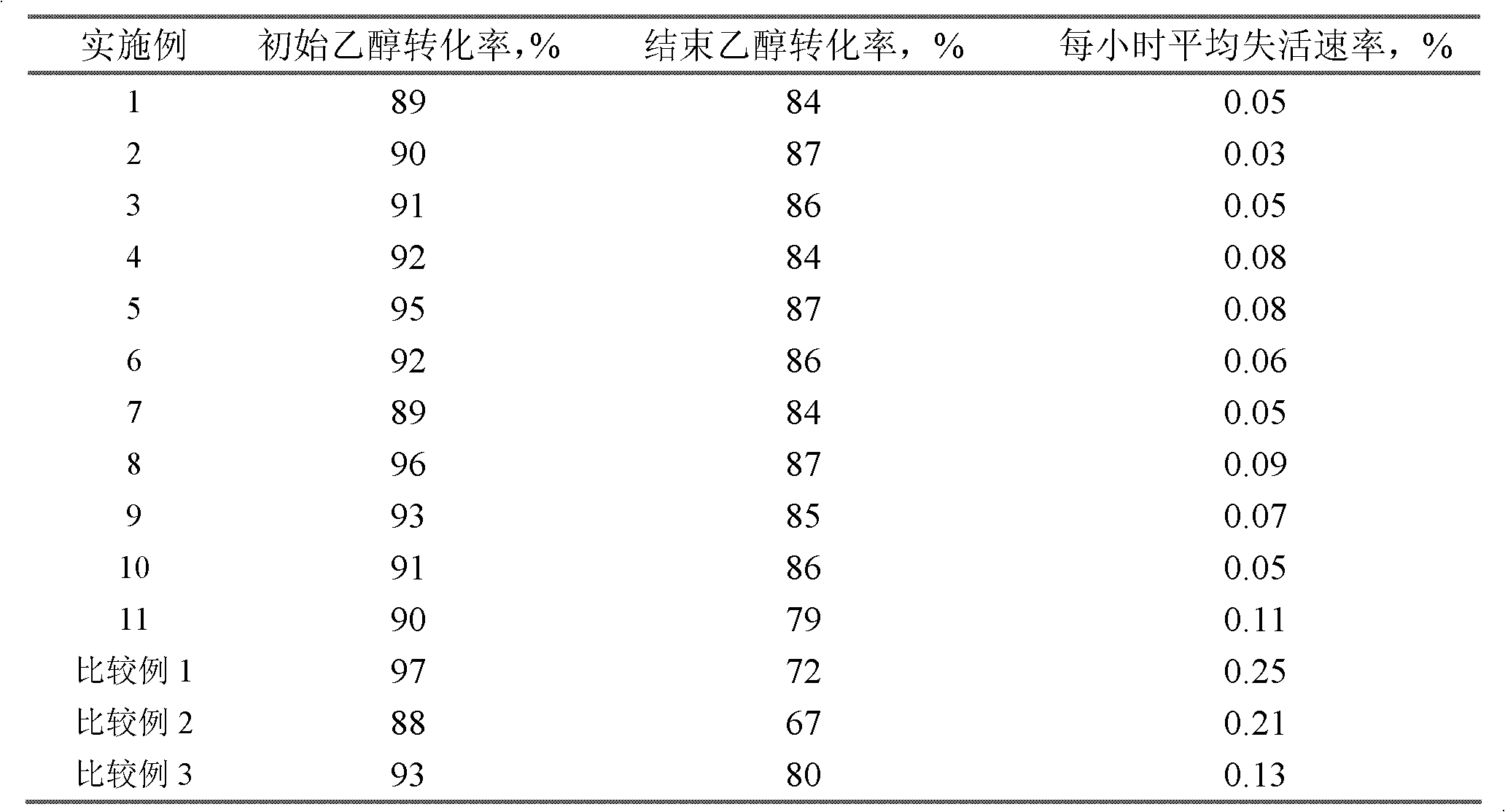

[0025] With [embodiment 1], just change the SiO of catalyst 2 / Al 2 o 3 Molar ratio, binder-free ZSM-5 molecular sieve grain size, catalyst containing La 2 o 3 amount, steam treatment and phosphoric acid treatment conditions. See Table 1 for details.

Embodiment 11

[0027] Same as [Example 1], but the catalyst contains Ce 2 o3 2.0% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com