High Si-content aluminum alloy anode imitation processing method and product thereof

An aluminum alloy product, anodic treatment technology, applied in the direction of pretreatment surface, device for coating liquid on the surface, special surface, etc., can solve the problems of easy yellowing of appearance, difficulty in obtaining white and beautiful appearance products, etc., and achieve high Effects of wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

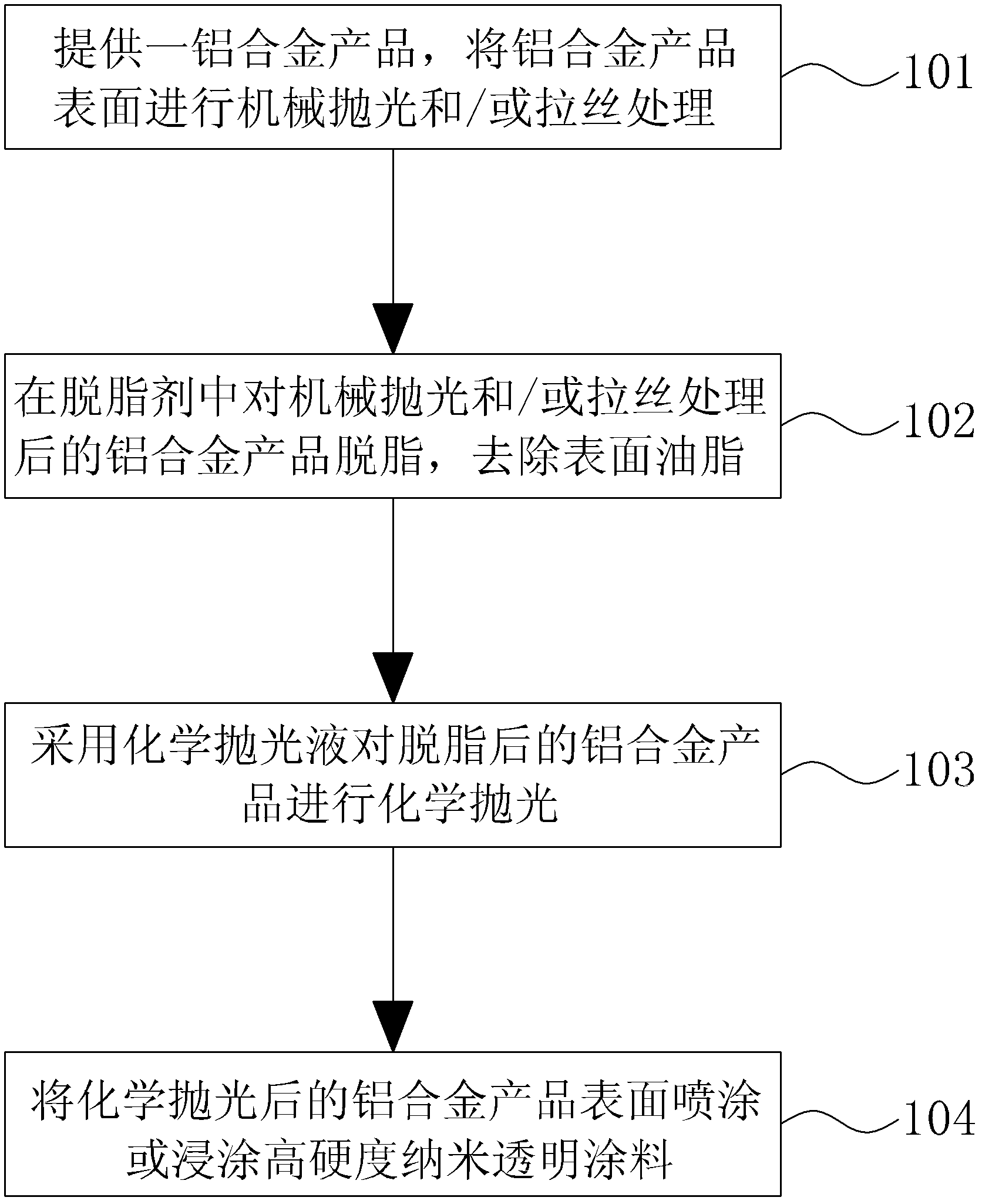

[0023] For a further understanding of the purpose of the present invention, method steps and functions, please refer to figure 1 , and detailed as follows:

[0024] In order to achieve the above object, the present invention provides a method for imitating anode treatment of aluminum alloys with high silicon content, which comprises the following steps:

[0025] Step 101: Provide an aluminum alloy product, and perform mechanical polishing and / or wire drawing on the surface of the aluminum alloy product;

[0026] Step 102: Degrease the mechanically polished and / or wire-drawn aluminum alloy product in a degreasing agent to remove surface grease;

[0027] Step 103: using a chemical polishing solution to chemically polish the degreased aluminum alloy product;

[0028] Step 104: Spray or dip-coat the surface of the chemically polished aluminum alloy product with a high-hardness nano-transparent coating.

[0029] Wherein, the high silicon content refers to that the mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com