Catalyst for arene shape selective reaction and preparation method thereof

A technology for catalysts and aromatics, applied in the field of catalysts and their preparation, can solve the problems of low catalyst strength and low catalyst shape selectivity, and achieve the effects of simple preparation methods, low porosity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

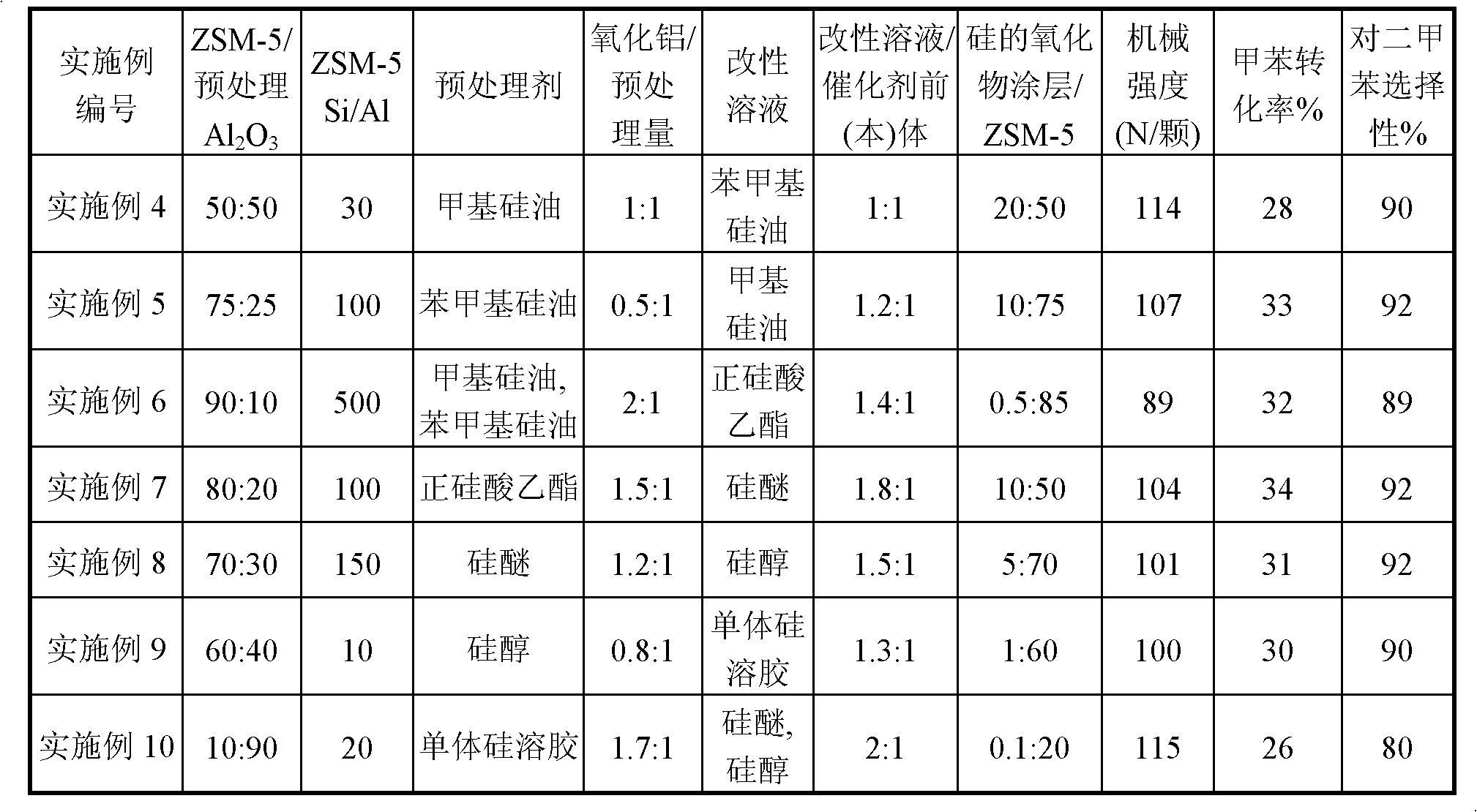

Examples

Embodiment 1

[0014] Mix 10g of alumina with 5g of methicone, grind for 20 minutes, and let stand for 2 hours. Then it is mixed evenly with 90 g of hydrogen-type ZSM-5 zeolite with a silicon-aluminum ratio of 60, shaped, dried, and calcined at 500° C. for 4 hours to obtain a catalyst precursor.

[0015] Put the catalyst precursor into 120g of methyl silicone oil solution, carry out the chemical liquid phase deposition reaction at 25°C for 3 hours, filter and dry it, and bake it in an air atmosphere at 500°C for 4 hours to obtain a catalyst body.

[0016] Then, the above-mentioned steps of the modified catalytic body were continued to be modified by chemical liquid phase deposition for 3 times. The mechanical strength of the obtained catalyst was 110N / particle. The catalyst was evaluated at 435°C and a pressure of 2.0mpa, using pure toluene as a raw material, and taking samples for analysis after 2 hours of reaction. It is calculated that the conversion rate of toluene in the toluene shape...

Embodiment 2

[0018] 20 g of alumina was mixed with 15 g of tetraethyl orthosilicate, milled for 60 minutes, and allowed to stand for 4 hours. Then it is mixed evenly with 80 g of hydrogen-type ZSM-5 zeolite with a silicon-aluminum ratio of 80, shaped, dried, and calcined at 450° C. for 3 hours to obtain a catalyst precursor.

[0019] Put the catalyst precursor into 140g of phenylmethyl silicone oil solution, carry out the chemical liquid phase deposition reaction at 25°C for 3 hours, filter and dry it, and roast it under the air atmosphere of 450°C for 3 hours to obtain the primary modified catalyst .

[0020] Then the catalyst body was modified by chemical liquid phase deposition for 2 times according to the above steps. The mechanical strength of the obtained catalyst was 105 N / particle. The catalyst was evaluated at 400°C and a pressure of 2.0mpa. Pure toluene and methanol were used as raw materials, and the molar ratio of toluene to methanol was 2:1. After 2 hours of reaction, sample...

Embodiment 3

[0022] Mix 30g of alumina with 30g of tetraethyl orthosilicate, grind for 45 minutes, and let stand for 4 hours. Then it is mixed evenly with 70 g of hydrogen-type ZSM-5 zeolite with a silicon-to-aluminum ratio of 75, shaped, dried, and calcined at 450° C. for 3 hours to obtain a catalyst precursor.

[0023] Put the catalyst precursor into 135g tetraethyl orthosilicate solution, carry out the chemical liquid phase deposition reaction at 25°C for 3 hours, filter, dry, and roast at 550°C for 3 hours in an air atmosphere to obtain the catalyst body.

[0024] Then the catalyst body was modified by chemical liquid phase deposition for one time according to the above steps. The mechanical strength of the obtained catalyst was 118N / particle. The catalyst was evaluated at 450°C and a pressure of 2.0mpa, using pure ethylbenzene as a raw material, and taking samples for analysis after 2 hours of reaction. It is calculated that the ethylbenzene conversion rate in the ethylbenzene selec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com