Illumination device having a heat sink and method for directing a light bundle emitted by an illumination device

A lighting device and cooling body technology, which is applied to the cooling/heating device of the lighting device, the parts of the lighting device, the lighting device, etc., can solve the problem of ineffective heat conduction, and achieve the reduction of transfer thermal resistance, easy realization and improvement cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

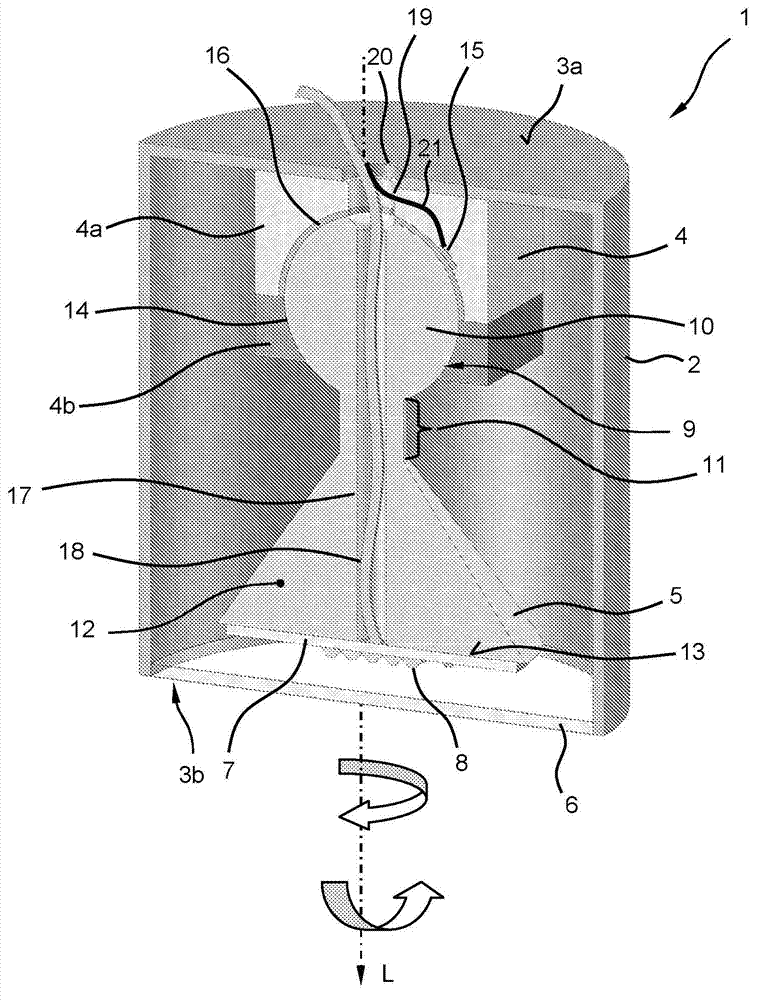

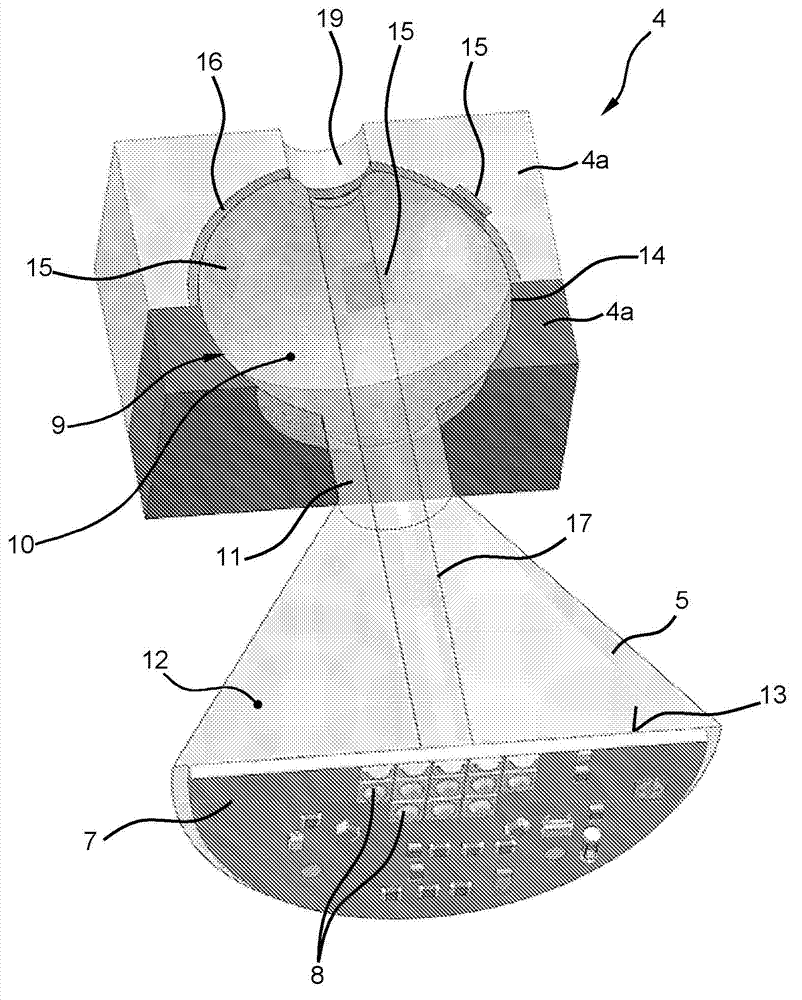

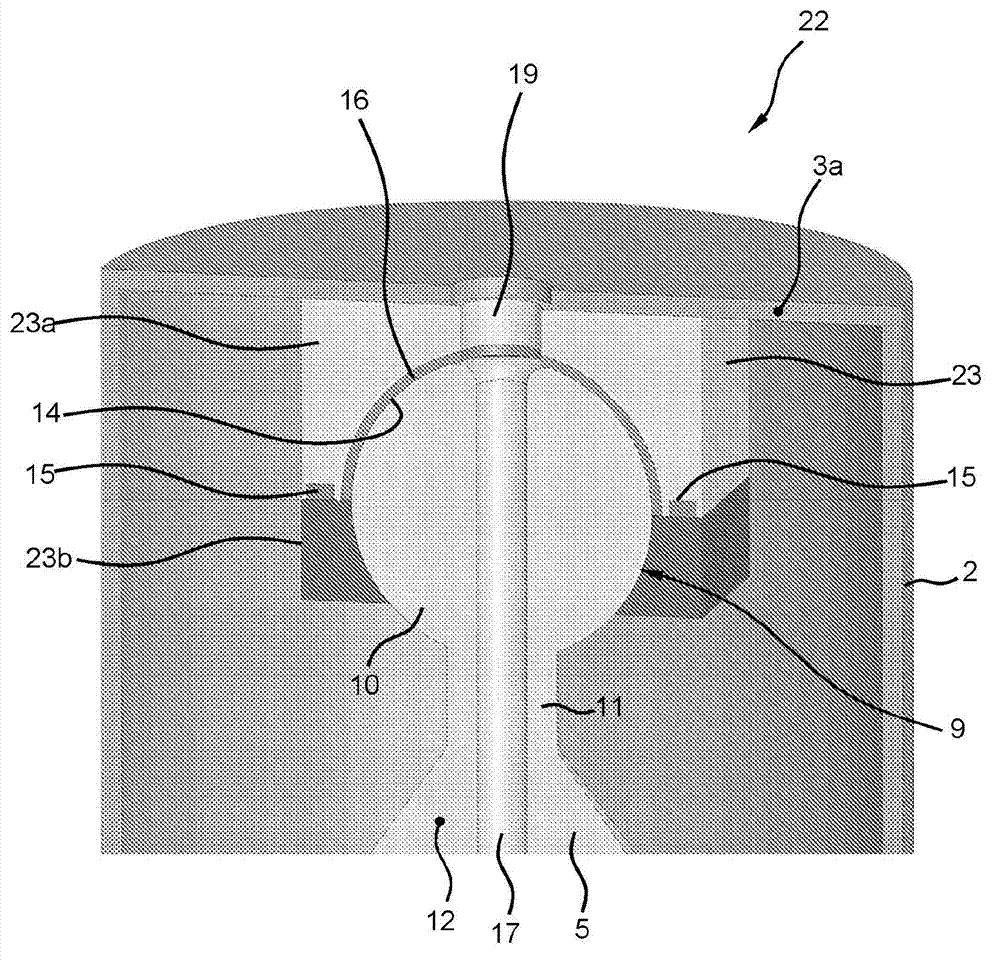

[0041] figure 1 An oblique sectional view of the lighting device 1 according to the first embodiment is shown. The lighting device 1 has a hollow-cylindrical housing 2 , on a closed cover surface 3 a of which a support 4 is fastened inside. The carrier 4 holds or carries a cooling body 5 , wherein the cooling body 5 extends from the carrier 4 in the direction of the open cover surface 3 b of the housing 2 opposite the closed cover surface 3 a . The open cover surface 3 b is covered by means of a disc-shaped and light-permeable cover 6 .

[0042] The carrier 4 forms a spherically-truncated recess in the form of a socket 9 for accommodating a spherical-head-shaped fastening region 10 of the heat sink 5 . The spherical fastening region 10 is the rear end of the heat sink 5 . In order to introduce a ball-shaped fastening area into the joint socket 9, the bracket 4 is designed in two parts, that is to say, with a first bracket part 4a fastened to the cover surface 3a and a The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com