Simulated test device and method for corrosion nearby suction port of downhole oil pump

A simulation test and oil well pump technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of inability to simulate the influence of casing corrosion, different pertinence, and no production string structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

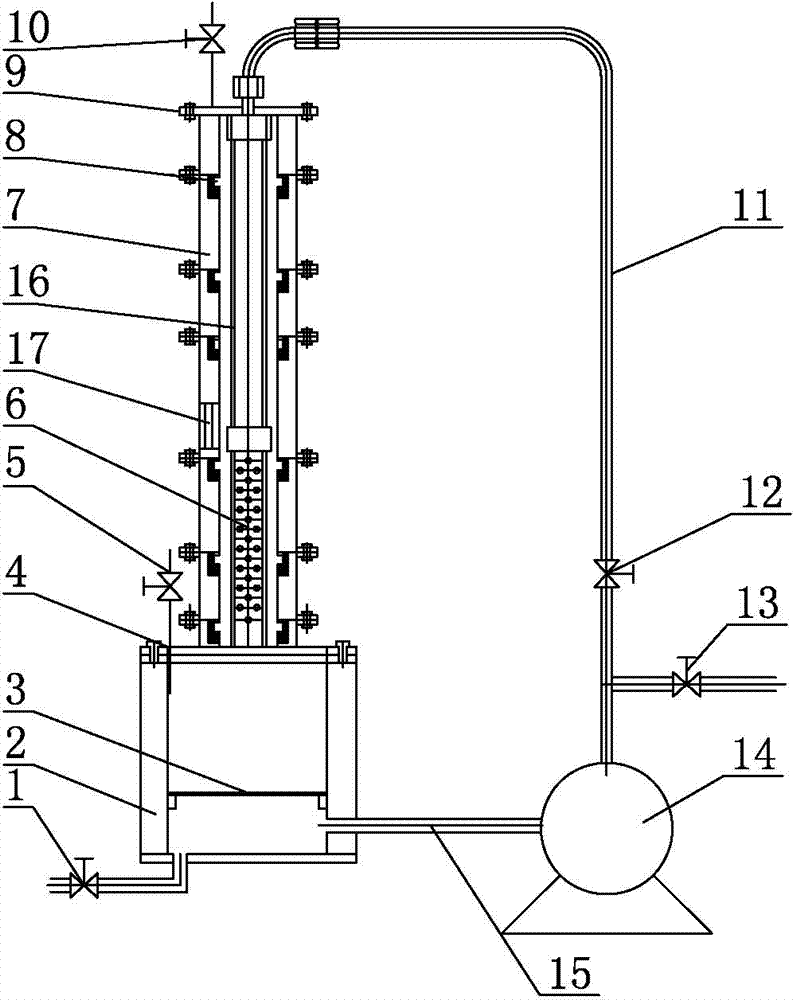

[0021] As shown in the figure, it is a corrosion simulation test device near the suction port of an downhole oil well pump, including a buffer container 4, a liquid discharge valve 1 is provided at the bottom of the buffer container 4, an air filling valve 5 is provided on the buffer container 4, and the inside of the buffer container 4 A heater 2 is provided, and the buffer container 4 is connected to the outlet of the plunger type metering pump 14 through the liquid return pipe 15. The buffer container 4 is provided with a blocking partition 3, and the connection position between the liquid return pipe 15 and the buffer container 4 is located at the Below the partition 3; the top of the buffer container 4 is connected with an upright screen pipe 6, the upper end of the screen pipe 6 is connected with an oil pipe 16, and the upper end of the oil pipe 16 is connected to the inlet of the plunger type metering pump 14 through a high-pressure double-layer hose 11, A shut-off valve...

Embodiment 2

[0024] A corrosion simulation test method near the suction port of an downhole oil well pump, comprising the following steps:

[0025] 1) After weighing multiple test coupons, install them in each sample slot;

[0026] 2) Take the downhole fluid as the test water sample, deoxygenate the test water sample and add it into the buffer container through the liquid filling valve, observe the test water sample from the observation window so that it submerges the screen pipe and the water level is not higher than the top of the observation window;

[0027] 3) Add a certain amount of CO through the gas filling valve 2 , CO 2 The amount of addition and the CO under the formation 2 The content is equivalent, and then, fill the annular space in the main standpipe above the water level with N through the gas filling valve 2 Pressurize to the formation pressure at the pump hang position of the pressure test simulation well;

[0028] 4) The heater heats the test water sample to the formati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com