High-flow high-pressure pneumatic switch valve

A pneumatic switch valve, large flow technology, applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of increasing device instability, precision, strength, high airtight requirements, complex structure, etc., to achieve reduction Complexity and instability, fast and fast opening and closing, and the effect of meeting the requirements of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

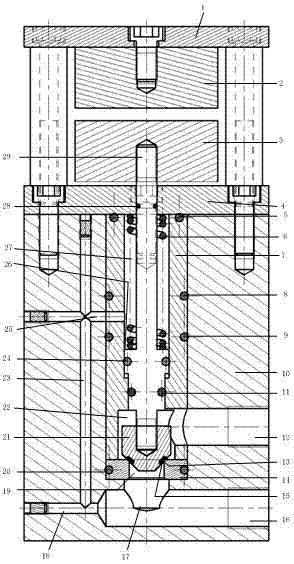

[0013] A high-flow high-pressure pneumatic switching valve of the present invention includes two parts: a main valve and an electromagnet. The electromagnet is located above the main valve and fixed on the main valve by bolts. The electromagnet includes an electromagnet bracket 1, an upper electromagnet 2 and The lower electromagnet 3 (due to the limitation of space, a single electromagnet cannot provide enough suction, and two electromagnets are used here), the upper electromagnet 2 is fixed on the electromagnet bracket 1 by bolts, and the lower electromagnet 3 is fastened to the valve On the core rod 29 protruding from the main valve, there is a counterbore in the center of the upper part of the electromagnet support, which is used to fix the electromagnet. Fixed on the valve cover; the main valve includes valve body 10, valve cover 4, valve sleeve 12, spring 11, valve core seat 14 and valve core part, valve body 10 is used as the bracket part of the main valve, and there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com