Continuous fiber-manufacturing device

A technology for manufacturing devices and fibers, applied in the field of electrospinning devices, can solve the problems of discontinuous liquid supply, coagulation of surface solution, large difference in jet size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

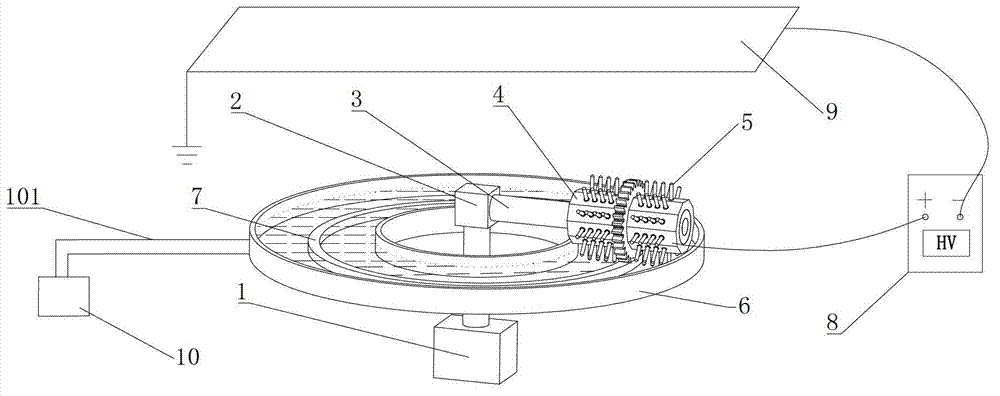

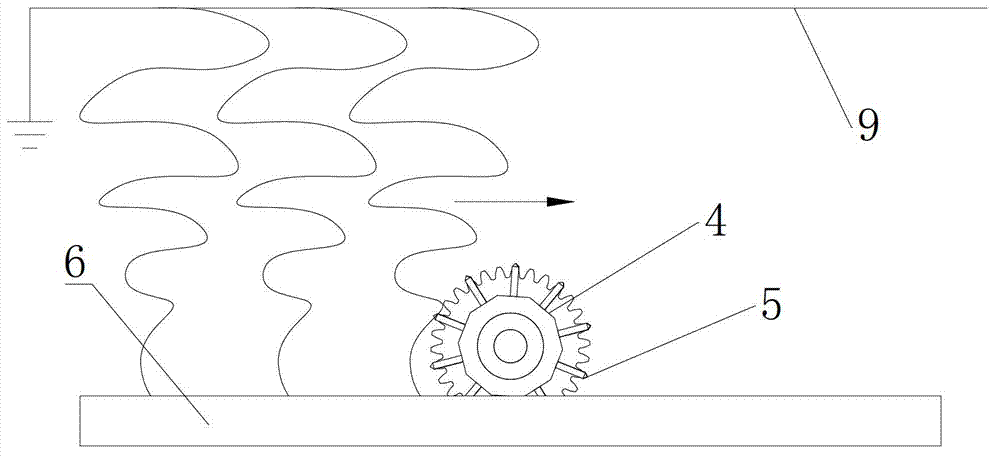

[0018] see figure 1 with 2 , the embodiment of the present invention is provided with a stepping motor 1, a connector 2, a rotating shaft 3, an inductive roller 4, a needle point array 5, an annular liquid storage tank 6, an annular rack 7, a DC high voltage power supply 8, a collecting plate 9 and a liquid supply device 10.

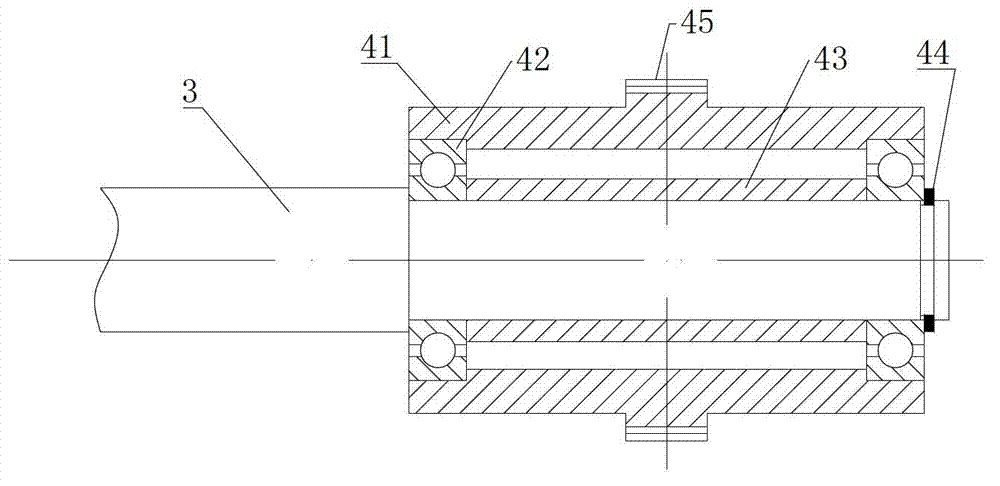

[0019] The output shaft of the stepping motor 1 is connected to the rotating shaft 3 through the connector 2, and the inducing roller 4 is connected to the rotating shaft 3 in rotation. The pinpoint array 5 is installed on the surface of the inducing roller 4, and each needlepoint of the pinpoint array 5 is connected to the threaded hole on the surface of the inducing roller 4 ( figure 1 with 2 not shown) screw connection. The induction roller 4 is composed of an induction wheel 41 , two ball bearings 42 , a sleeve 43 and a snap ring 44 , and the middle part of the induction wheel 41 is provided with a ring gear 45 . The inner ring of the ball beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com