Ultraviolet light curable coating with dewdrop effect and preparation method and coating method thereof

A technology of curing paint and ultraviolet light, which is applied in the field of paint, can solve the problems of alcohol resistance, G1 resistance, high temperature and high humidity resistance, etc., and achieve the effect of easy curing, good decorative effect and good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

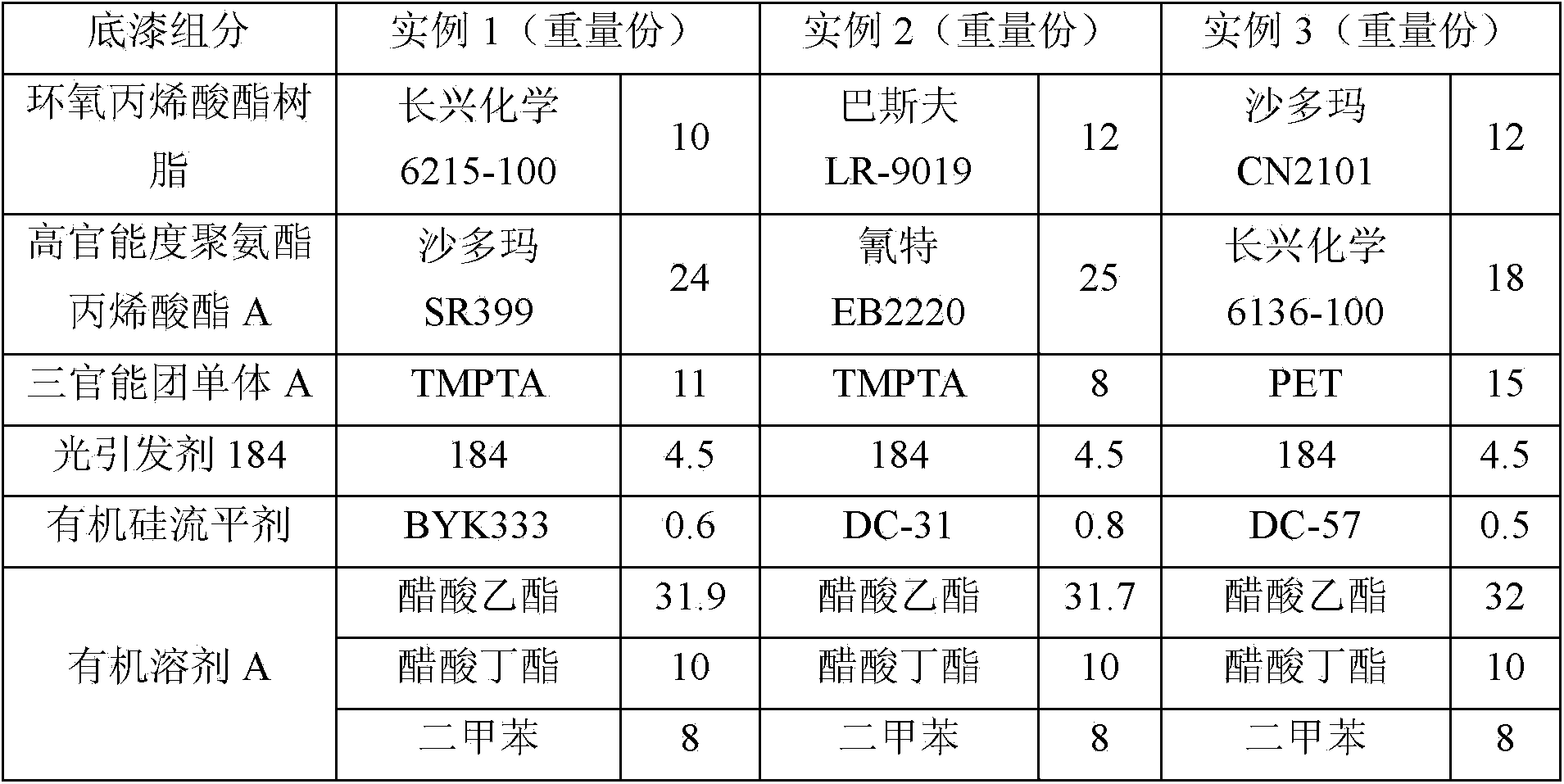

[0066] See Table 1 for the composition in parts by weight of the primer, and Table 2 for the composition in parts by weight of the topcoat.

[0067] Table 1

[0068]

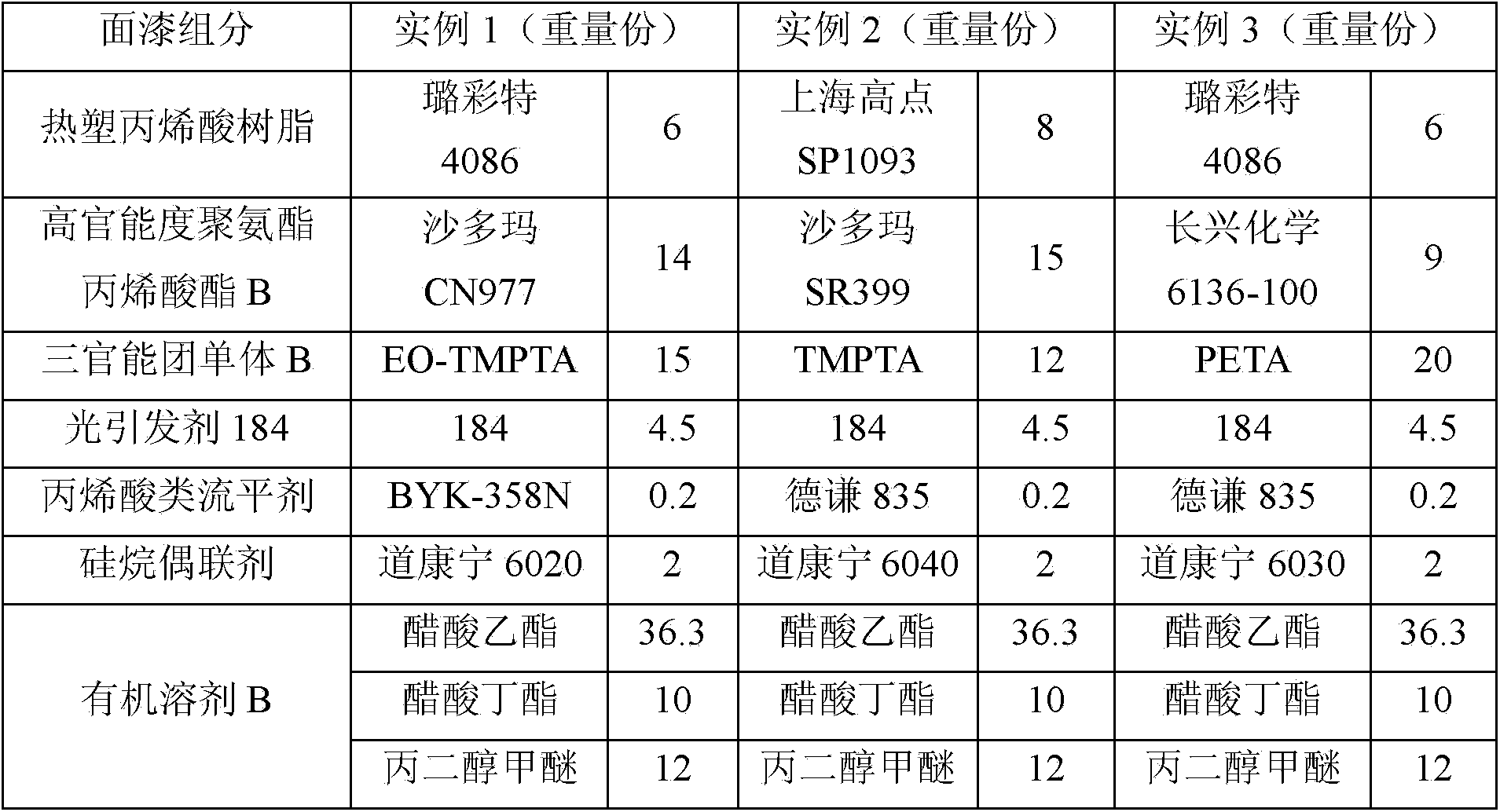

[0069] Table 2

[0070]

[0071] Accurately weigh each component according to the composition in parts by weight in Table 1, place it in a container for high-speed dispersion, disperse and stir evenly, and then filter with a filtration accuracy of 1um. After the filter is completed, pack it to obtain a primer. During the packaging process, it is necessary to avoid light, heat and collision.

[0072] Accurately weigh each component according to the composition in parts by weight in Table 2, place it in a container for high-speed dispersion, disperse and stir evenly, then filter with a filtering accuracy of 1um, and pack after filtering to obtain a top coat. During the packaging process, it is necessary to avoid light, heat and collision.

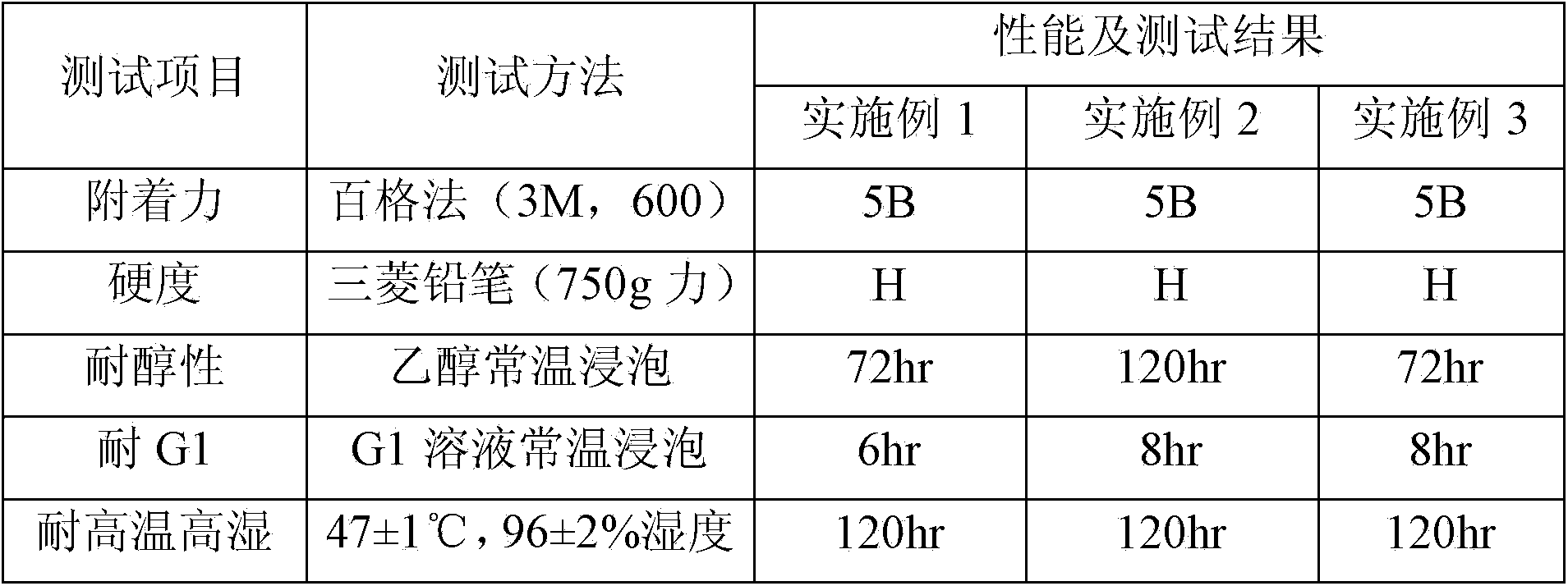

[0073] Apply the above coating on the plastic substrate, the coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com