Wood flour modifier, wood flour modified thereby, and preparation method of wood flour

A modifier and wood powder technology, which is applied in the field of wood processing, can solve the problems of reducing the performance of composite materials, affecting interface compatibility, weak interface layers, etc., and achieve the effects of increasing interlayer spacing, increasing suspension stability, and reducing moisture absorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

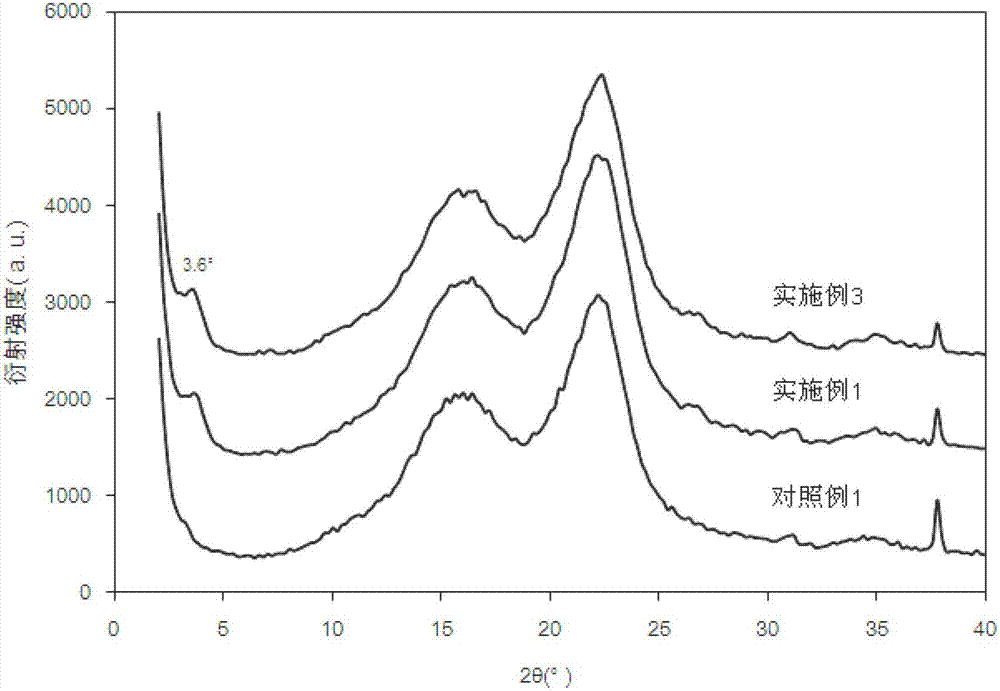

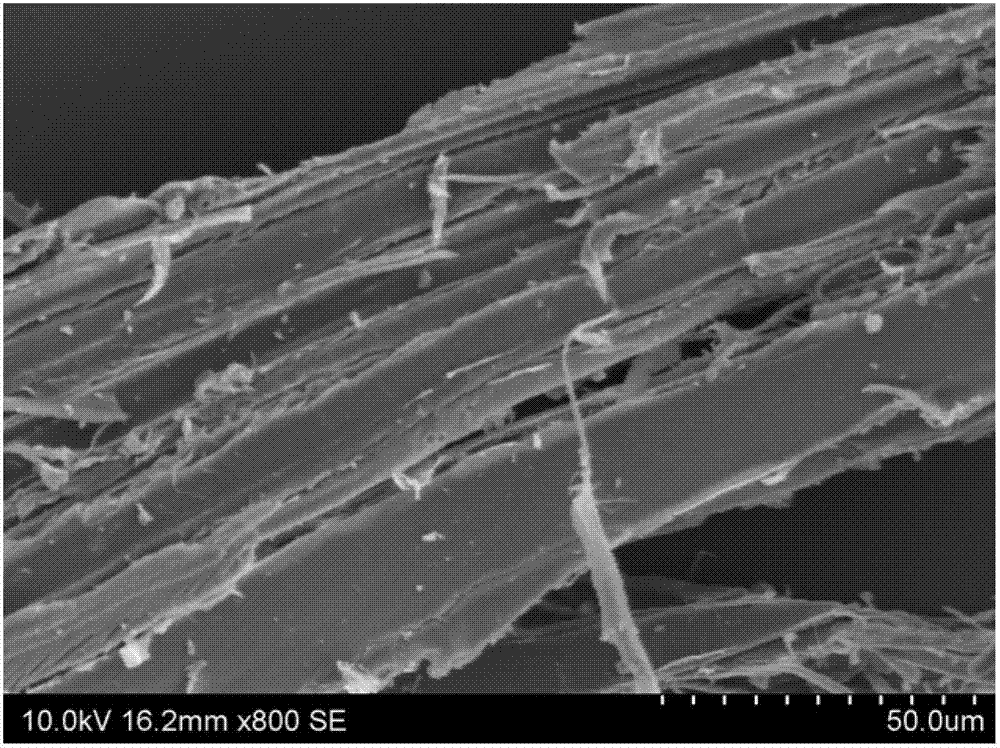

Embodiment 1

[0053] The wood flour is Populus tomentasa Carr., 10-60 mesh, Hebei Gaocheng Xingda Wood Flour Factory; Na-MMT, 200 mesh, cation exchange capacity (CEC) is 90mmol / 100g, the interlayer distance is 1.459nm, Zhejiang Fenghong Clay Chemical Co., Ltd.; didecyldimethylammonium chloride (DDAC), mass percent concentration 70%, Sanbo Biochemical Technology (Shanghai) Co., Ltd.; polyethylene glycol (PEG), molecular weight 1000, Fushun Jiahua Chemical Co., Ltd., Liaoning Province; polylactic acid (poly L-, Yisheng AI-1001 type), number average molecular weight 80000, density 1.25g / cm 3 , Melt index 10-20g / min, Shenzhen Guanghua Weiye Industrial Co., Ltd.

[0054] (1) Prepare modifier

[0055] Add sodium montmorillonite (Na-MMT), didecyldimethylammonium chloride (DDAC), polyethylene glycol (PEG-1000) with a molecular weight of 1000, and deionized water into a ball mill (Chunlong Experimental Instrument Co., Ltd. ) for ball mill dispersion treatment, in which there are 75 small balls wi...

Embodiment 2

[0061] During the experiment, except that Populus tomentasa Carr., 60-80 mesh, was used at Xingda Wood Flour Factory in Gaocheng, Hebei, the rest were the same as in Example 1.

Embodiment 3

[0063] Except that the mass percent concentration of the organic montmorillonite modifier used was 1%, the rest were the same as in Example 1 during the experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cation exchange capacity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com