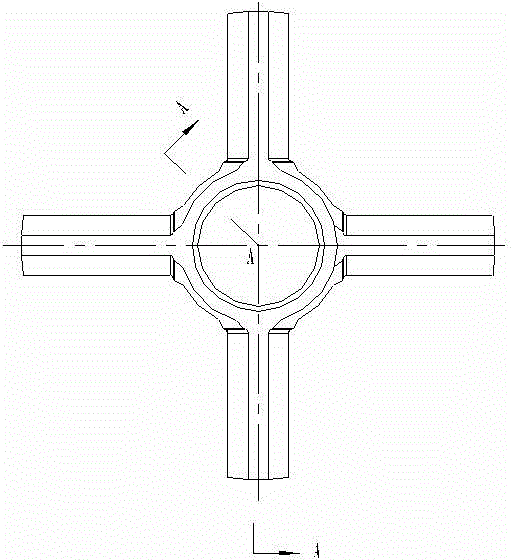

Secondary synchronous cold extruding forming production method for cross axles of automobile differentials and planetary reducers

A planetary reducer, automobile differential technology, applied in the direction of metal extrusion dies, etc., can solve the problems of increasing the scrap rate of parts, shortening the manufacturing time, wasting energy, etc., to reduce the scrap rate, shorten the manufacturing time, avoid rough crystal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

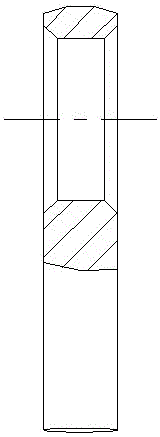

[0021] The manufacturing method of secondary synchronous cold extrusion molding of automobile differential and planetary reducer cross shaft of the present invention is characterized in that it comprises the following steps:

[0022] (1) According to the process design requirements, the raw material (alloy structural steel that meets the process requirements) is cut into material sections, the surface is ground by centerless grinding, the crack is inspected, and the material sections that do not meet the requirements are removed after inspection; the qualified material is section, spray the lubricant, and then dry the lubricant;

[0023] (2) The first annealing heat treatment: heat the material section to 830°C~870°C, keep it warm for 8-14 hours, and drop it to 680°C + Cool down to 350°C after 15°C + 15°C, then take it out of the furnace and air cool to room temperature; it can be heated in a heating device, such as a power frequency furnace, an intermediate frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com