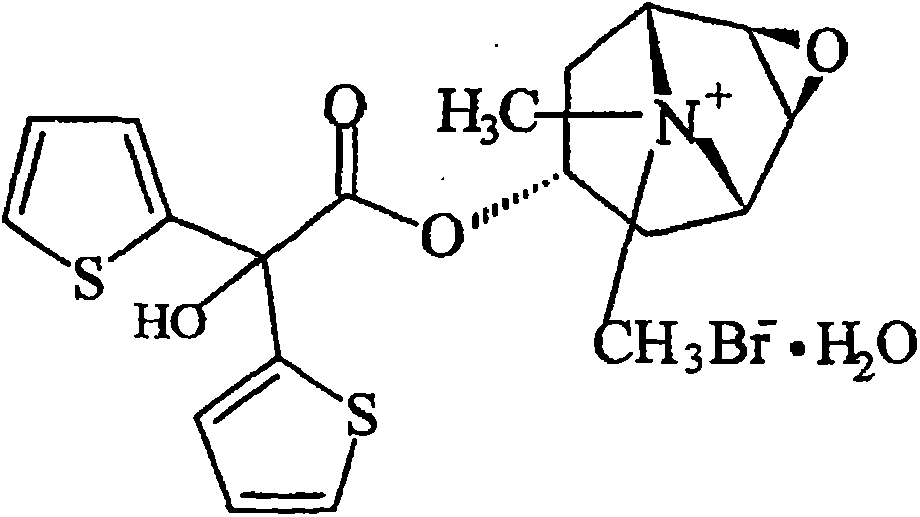

Tiotropium bromide powder inhalation and preparation method thereof

A technology of tiotropium bromide and powder spray, which is applied in the field of tiotropium bromide powder spray and its preparation, can solve the problems of ineffective preparation, unmentioned particle size range, difference in curative effect, etc., and achieve simple preparation process and improved The safety and effectiveness of medication, the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Raw material treatment: The tiotropium bromide raw material is pulverized by a jet mill, and then passed through an NGI device with an air flow rate of 60 L / min, and collected from No. 4-6 collection trays to obtain raw materials with a particle size range of 1.66-4.46 μm.

[0034] Take 1.8g of processed raw materials, 2500g of inhalable lactose, mix well, and fill capsules with a micro-filler to obtain tiotropium bromide powder.

Embodiment 2

[0036] Raw material treatment: The tiotropium bromide raw material is pulverized by a ball mill, and then passed through an NGI device with an airflow speed of 30L / min, and collected from No. 3-5 collection trays to obtain raw materials with a particle size range of 1.34-4.03 μm.

[0037] Take 1.8g of processed raw materials, 2000g of inhalable lactose, mix well, and fill capsules with a micro-filler to obtain tiotropium bromide powder.

Embodiment 3

[0039] Raw material treatment: The tiotropium bromide raw material is pulverized by a jet mill, and then passed through an NGI device with an air flow rate of 60 L / min, and collected from No. 4-6 collection trays to obtain raw materials with a particle size range of 1.66-4.46 μm.

[0040] Take 1.8g of processed raw materials, 2000g of inhalable lactose, mix well, and fill capsules with a micro-filler to obtain tiotropium bromide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com