Crystal flour wrapper as well as preparation method and application thereof

A dough and crystal technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of less research on crystal dough, difficulty in large-scale application, complicated process, etc., to achieve improved freeze-thaw stability, convenient operation, and high-tech simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0044] One, the preparation technology of frozen crystal dumpling

[0045] ① Mixing: fully mix the wheat starch, potato starch and acetic acidified cassava modified starch (Zhengzhou Chenyang Chemical Co., Ltd.) in the ingredients according to the proportion;

[0046] ②Blanching: Heat the remaining water in the ingredients to 85°C and evenly sprinkle it on the mixed ingredients, and stir it into a ball while spraying. After the dough is formed, continue to knead it repeatedly for 5 minutes with a kneading machine;

[0047] ③Molding: Press the formed dough into a dough, the thickness of the dough is 1.0mm;

[0048] ④ Filling: put fillings in the dough to make dumplings;

[0049] ⑤Steaming: Steam the wrapped dumplings in a steamer for 10 minutes and let cool to room temperature.

[0050] ⑥ Freezing: Place the finished dumplings in a -18°C refrigerator for frozen storage.

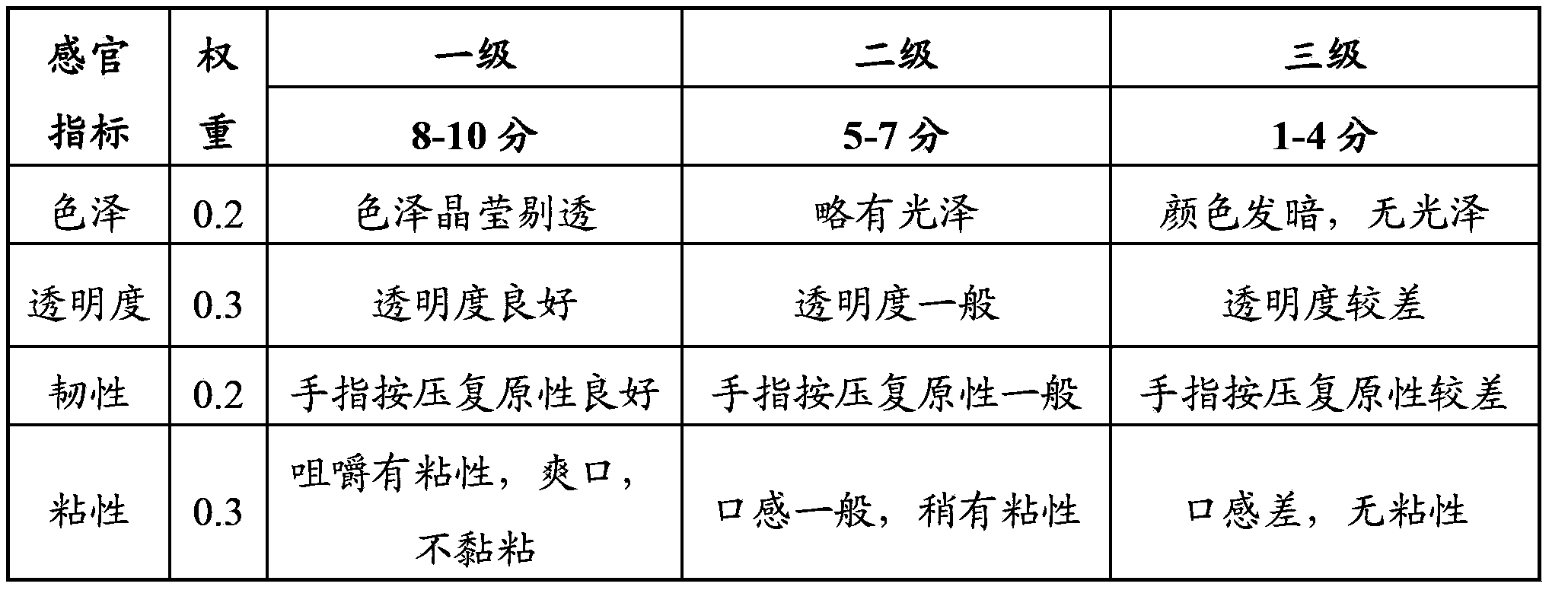

[0051] When evaluating the frozen crystal dumpling, it needs to be steamed and thawed, and the thawing s...

Embodiment 1

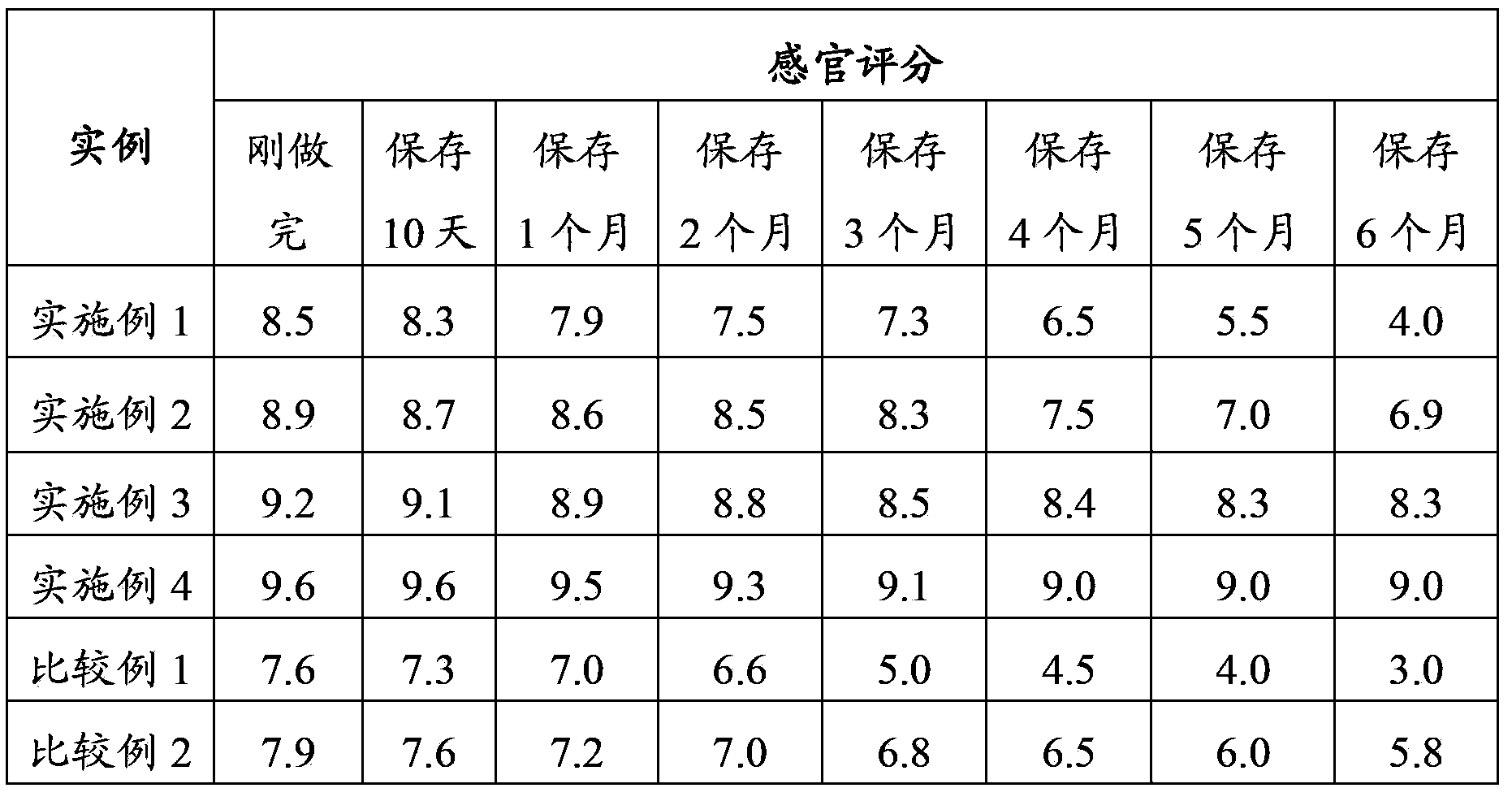

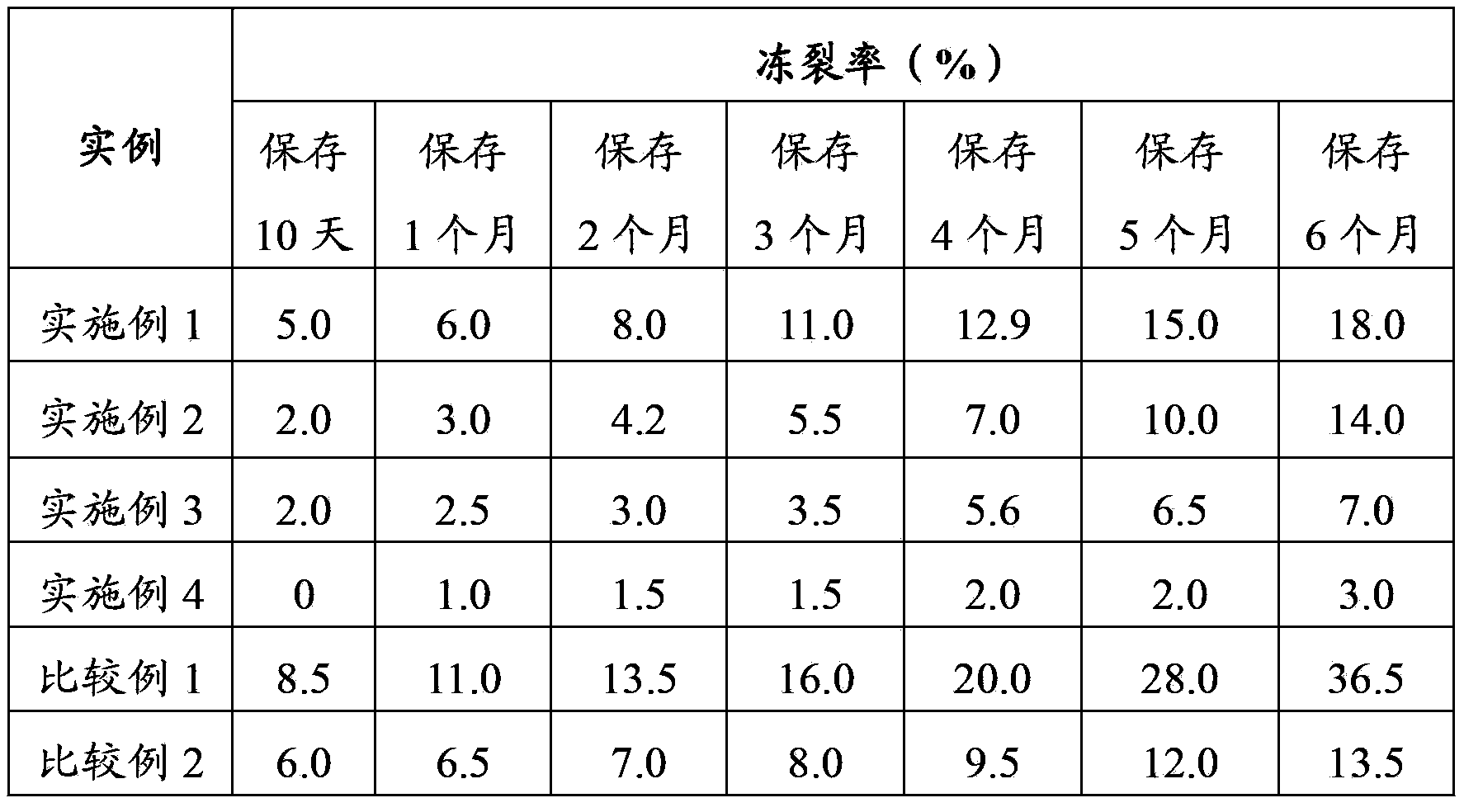

[0060] According to the production process of frozen crystal dumpling, take 20% wheat starch, 0.5% potato starch and 0.8% acetic acidified cassava modified starch, mix well, and heat the water with a balance of 78.7% to 85°C Afterwards, it is evenly sprinkled in the mixed ingredients, and quickly kneaded into dough after blanching, pressed the dough, stuffed, frozen and made into frozen crystal dough dumplings. The state of the crystal skin dumplings was subjected to sensory evaluation after freezing for 10 days, 1 month, 2 months, 3 months, 4 months, 5 months and 6 months, as well as the rate of freezing cracking and cooking. Determination of belly breaking rate.

Embodiment 2

[0062] According to the production process of frozen crystal dumpling, take 30% wheat starch, 1% potato starch and 2% acetic acidified tapioca modified starch, mix well, and heat the water with a balance of 67% to 85°C Afterwards, it is evenly sprinkled in the mixed ingredients, and quickly kneaded into dough after blanching, pressed dough, filled with stuffing, and frozen to make frozen crystal dough dumplings. The state of the crystal skin dumplings was subjected to sensory evaluation after freezing for 10 days, 1 month, 2 months, 3 months, 4 months, 5 months and 6 months, as well as the rate of freezing cracking and cooking. Determination of belly breaking rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com