Motor winding and electronic power switch combination assembly capable of switching output state

A power electronic switch, output state technology, applied in the shape/style/structure of winding conductors, electrical program control, program control in sequence/logic controllers, etc., can solve the problem of limited motor operating speed range and low starting torque , can not have too high no-load speed and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

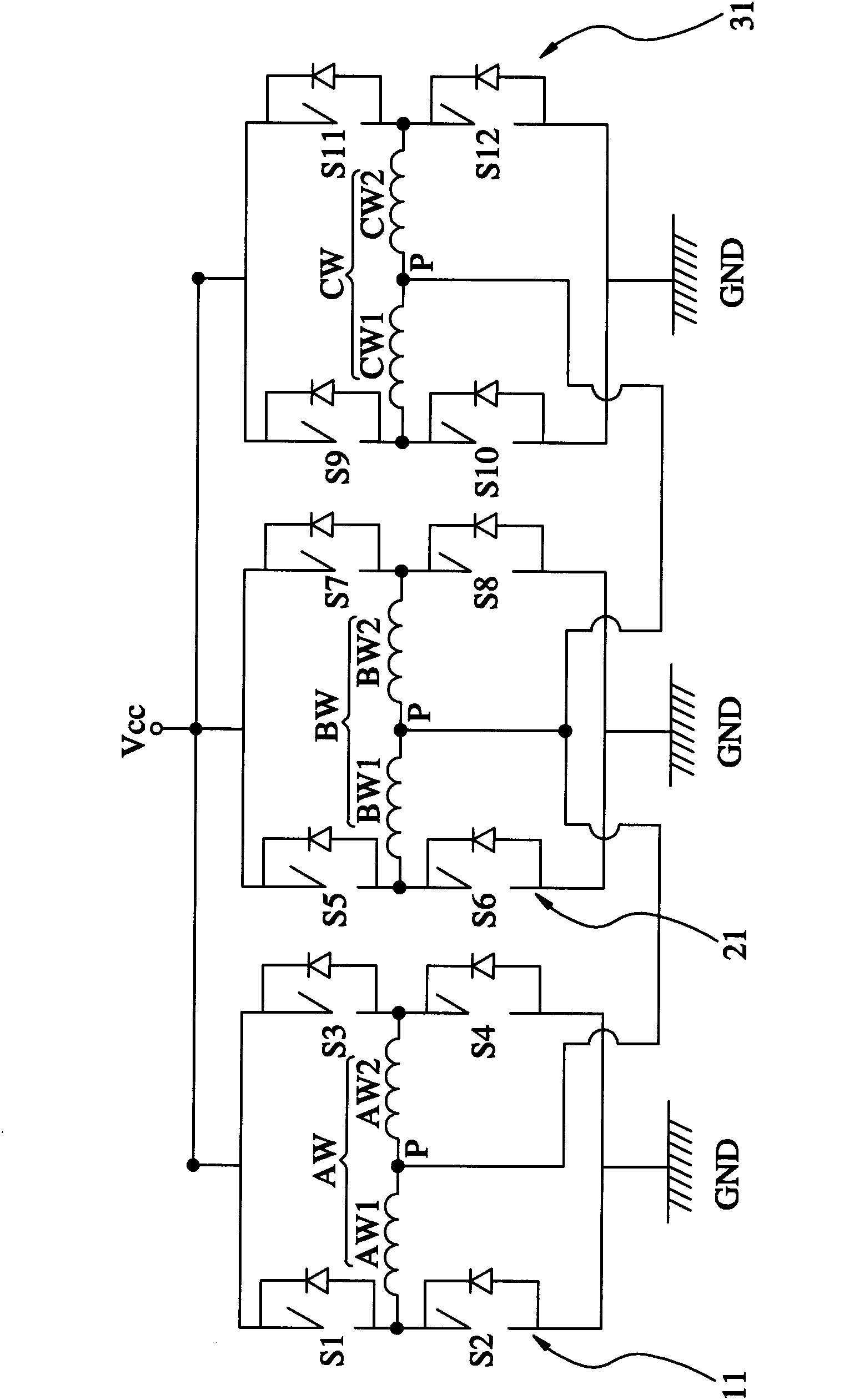

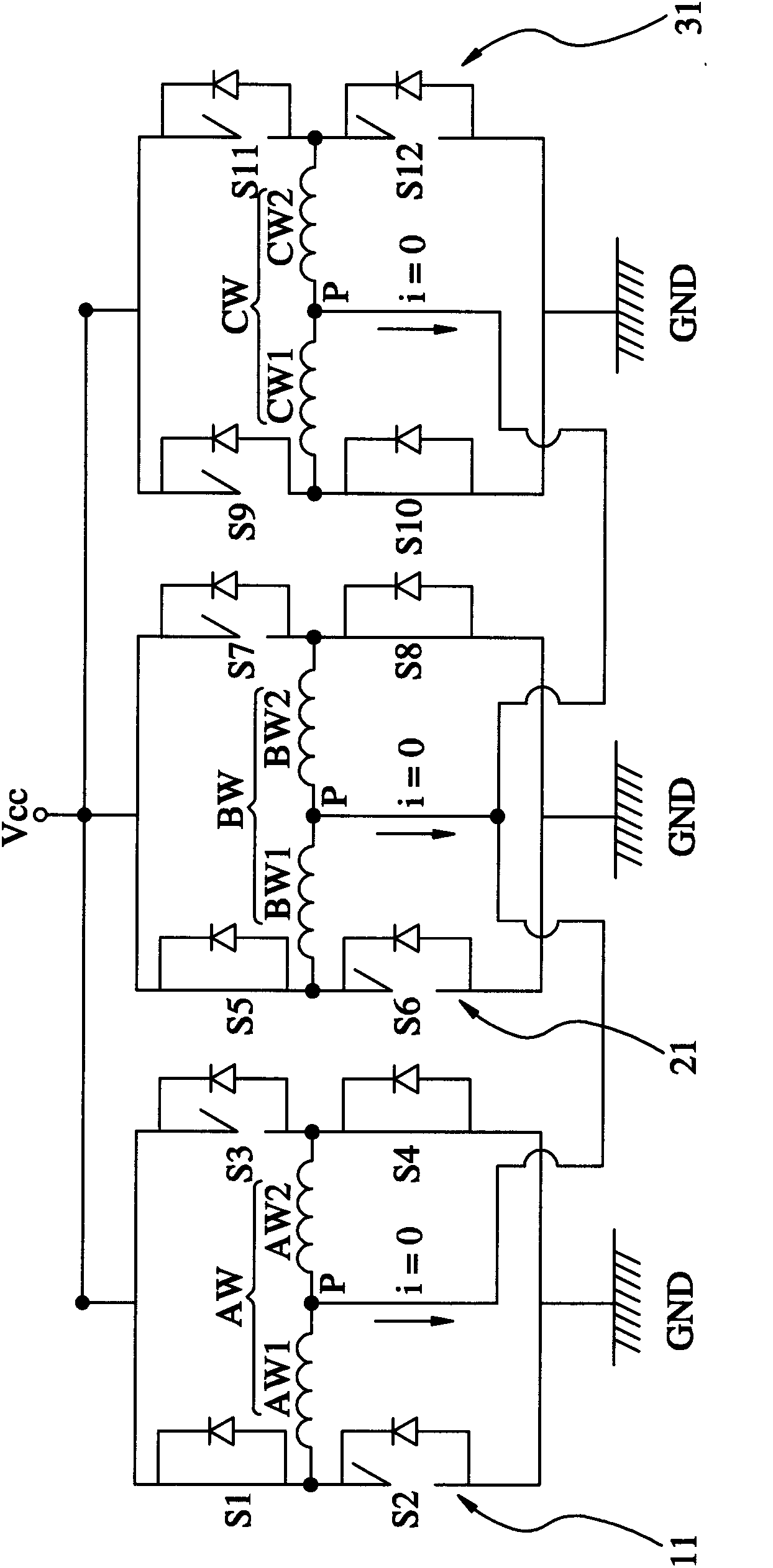

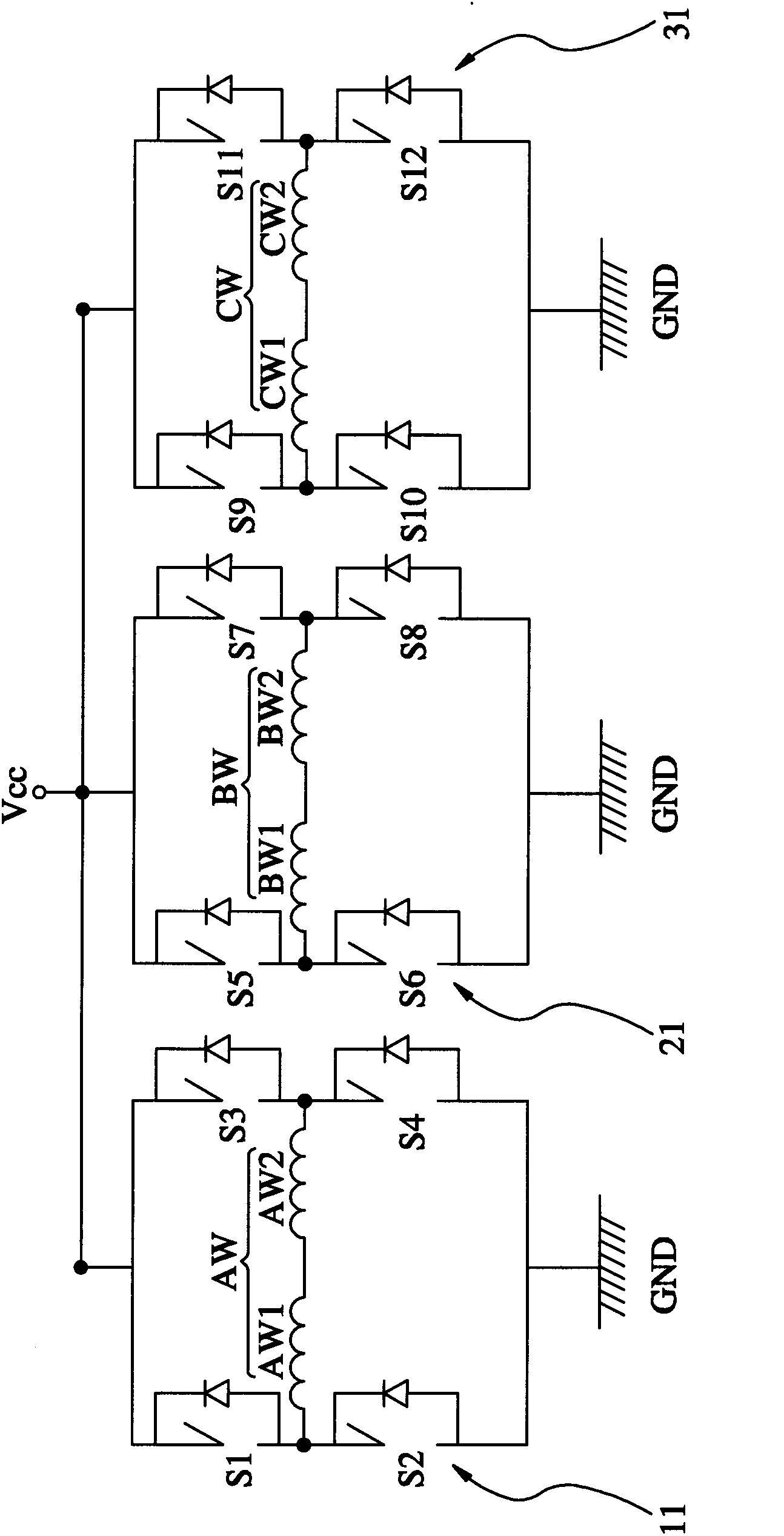

[0018] like figure 1 As shown, a combination assembly 10 of a motor winding and a power electronic switch that can switch the output state provided by a preferred embodiment of the present invention is mainly composed of a first winding AW, a first switch group 11, a first Two windings BW, a second switch group 21, a third winding CW, a third switch group 31 and a mode control means (not shown), wherein:

[0019] The first winding AW is divided into a first upper half winding AW1 and a first lower half winding AW2, the first upper half winding AW1 and the first lower half winding AW2 are connected to a common point P at one end, and The first upper half winding AW1 is symmetrical to the first lower half winding AW2. In this embodiment, the symmetry of the windings refers to the fact that the upper half winding and the lower half winding have the same number of turns as an example, but the number of turns is similar. It is also within the allowable range, that is, the aforesa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com