Wrench

A wrench and wrench head technology, applied in the field of wrenches, can solve problems such as wrenches not working properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A wrench, in particular a combined graded wrench, comprising a large size wrench head and a small size wrench head, both of the large size wrench head and the small size wrench head include at least one section of a prismatic member, and the large size The smallest size section of the wrench is larger than the largest size section of the small size wrench. The bottom of the large-size wrench is provided with a connection groove, and the upper part of the small-size wrench is provided with a connecting piece adapted to the connection groove. This connecting piece can be inserted into the connection groove to complete the connection between the large-size wrench and the small-size wrench. connect.

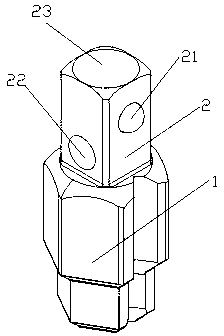

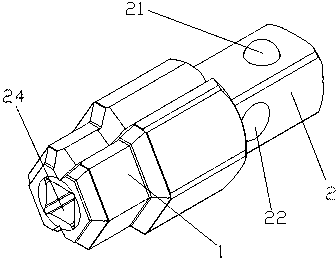

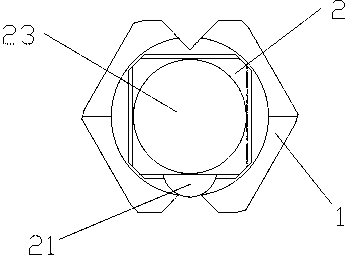

[0059] Please refer to figure 1 , figure 2 and image 3 , the upper part of the large size wrench 1 is provided with a first connector 2, and the first connector 2 is integrally made with the large size wrench 1. The first connecting head 2 is in the shape of a cuboid. An...

Embodiment 2

[0065] A wrench, in particular a combined graded wrench, comprising a large size wrench head and a small size wrench head, both of the large size wrench head and the small size wrench head include at least one section of a prismatic member, and the large size The smallest size section of the wrench is larger than the largest size section of the small size wrench. The bottom of the large-size wrench is provided with a connection groove, and the upper part of the small-size wrench is provided with a connecting piece adapted to the connection groove. This connecting piece can be inserted into the connection groove to complete the connection between the large-size wrench and the small-size wrench. connect.

[0066] The structure of this embodiment is similar to that of Embodiment 1, the difference is that no opening is provided on the first connecting head.

Embodiment 3

[0068] Please refer to Figure 9 , Figure 10 and Figure 11 , a wrench, including at least one specification of the wrench 6, in this embodiment, the wrench 6 includes 2 to 6 sections of prismatic components of different specifications, from small to large, in a stepped shape, each prismatic component The two corresponding side surfaces are respectively provided with V-shaped grooves.

[0069] A connecting head 7 is arranged on the top of the wrench head 6, the shape of the connecting head 7 is not limited, it can be cylindrical or cuboid, and in this specific embodiment, the connecting head 7 is cuboid. One side of the connecting head 7 is provided with an opening 73 for connecting with the vertical rod 5, and a steel ball assembly 71 is also arranged on the side of the connecting head 7, the steel ball assembly 71 and the opening 73 can be arranged on the same side, It can also be arranged on two different sides, and the present invention is not limited thereto. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com