Plasma treatment device

A processing device, plasma technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of unevenness, low plasma efficiency, uneven plasma gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

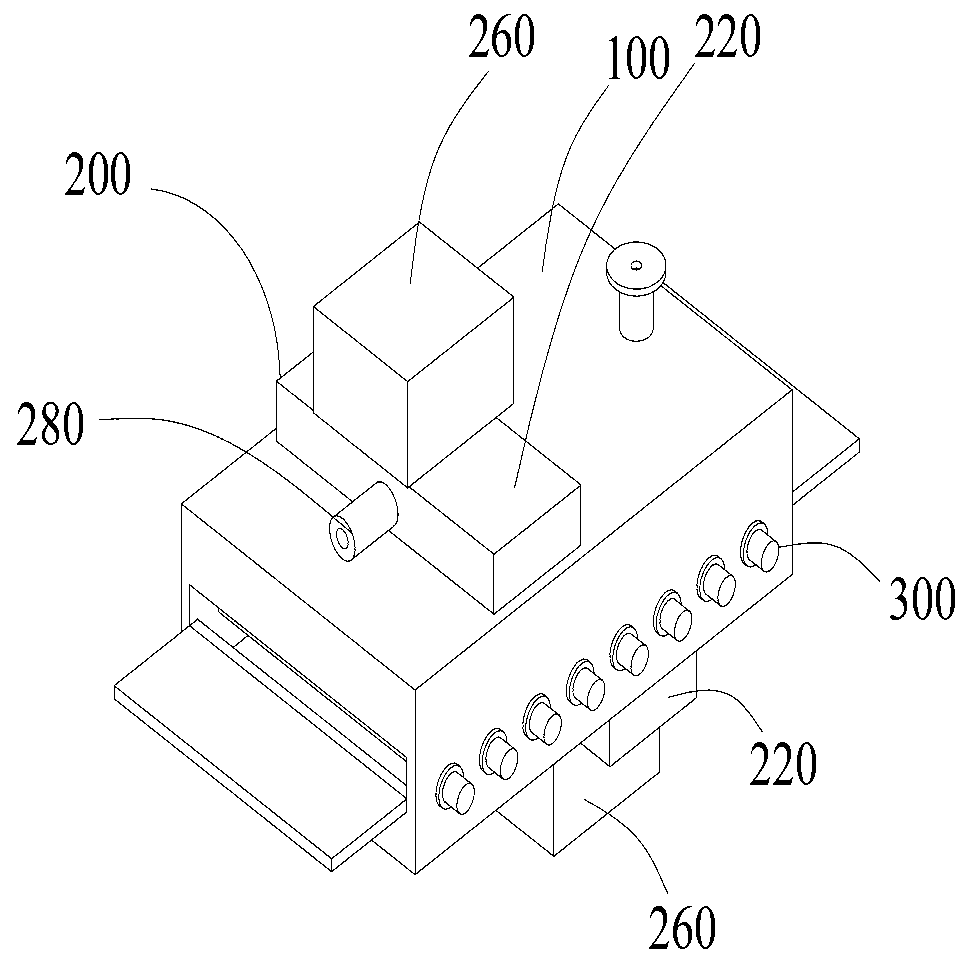

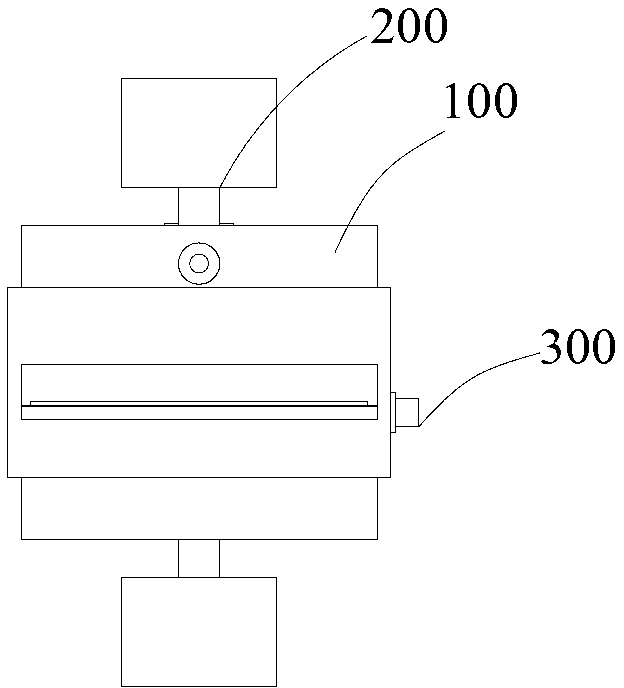

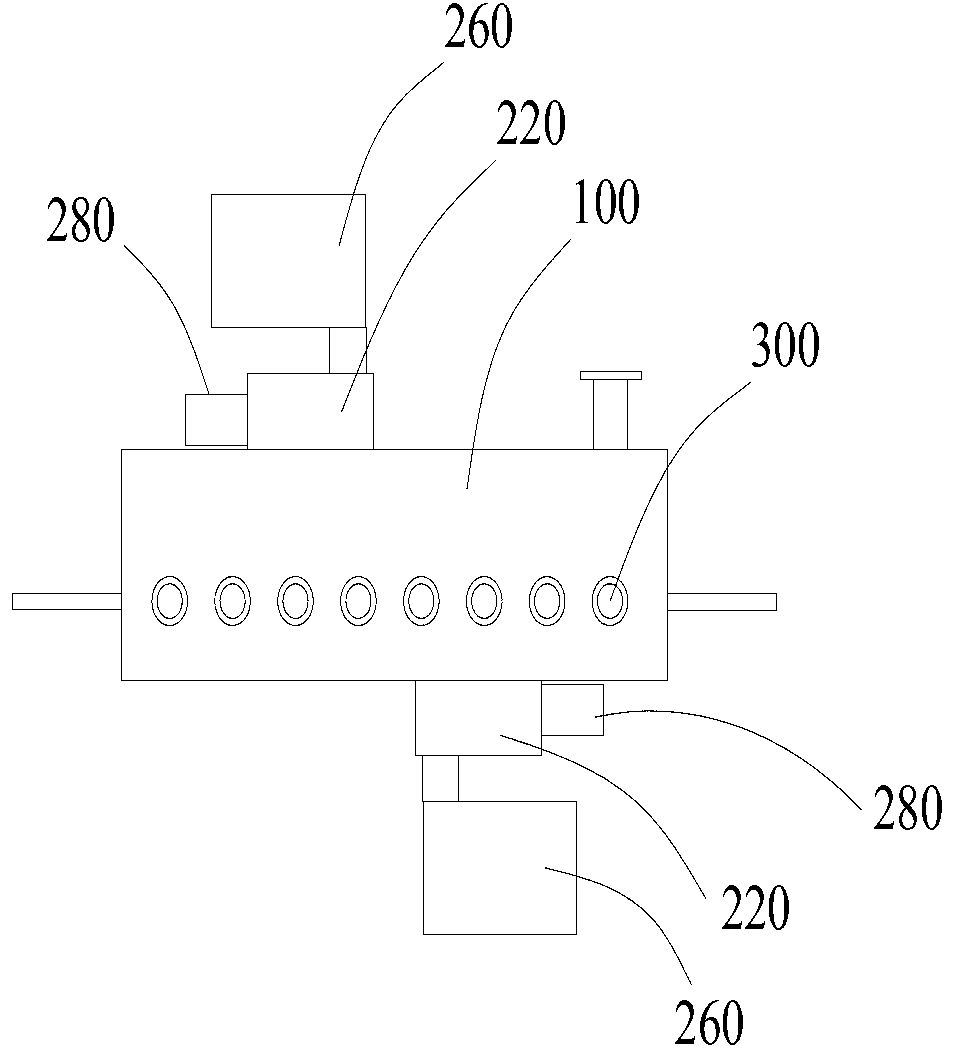

[0028] Such as figure 1 , figure 2 , Figure 5 , Figure 6 As shown, a plasma processing device includes a vacuum chamber 100 and a plasma generation assembly 200, and the plasma generation assembly 200 includes:

[0029] The plasma generation chamber 220 is opened on the chamber wall of the vacuum chamber body 100;

[0030] The electrode module 240 is arranged in the plasma generating chamber 220, the discharge end of the electrode module 240 is facing the inside of the vacuum chamber 100, and the electrode module 240 is composed of a plurality of tubular electrodes 242 arranged in a parallel matrix composition;

[0031] A microwave plasma excitation source 260 is electrically connected to the electrode module 240;

[0032] The gas delivery pipe 280 communicates with the plasma generation chamber 220 from the side wall of the plasma ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com