Method for determining and compensating engine blow-through air

An engine and air technology, applied to engine components, combustion engines, engine control, etc., can solve problems such as difficult to maintain catalyst balance and adjust cylinder air-fuel ratio, so as to improve conversion efficiency and reduce vehicle emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

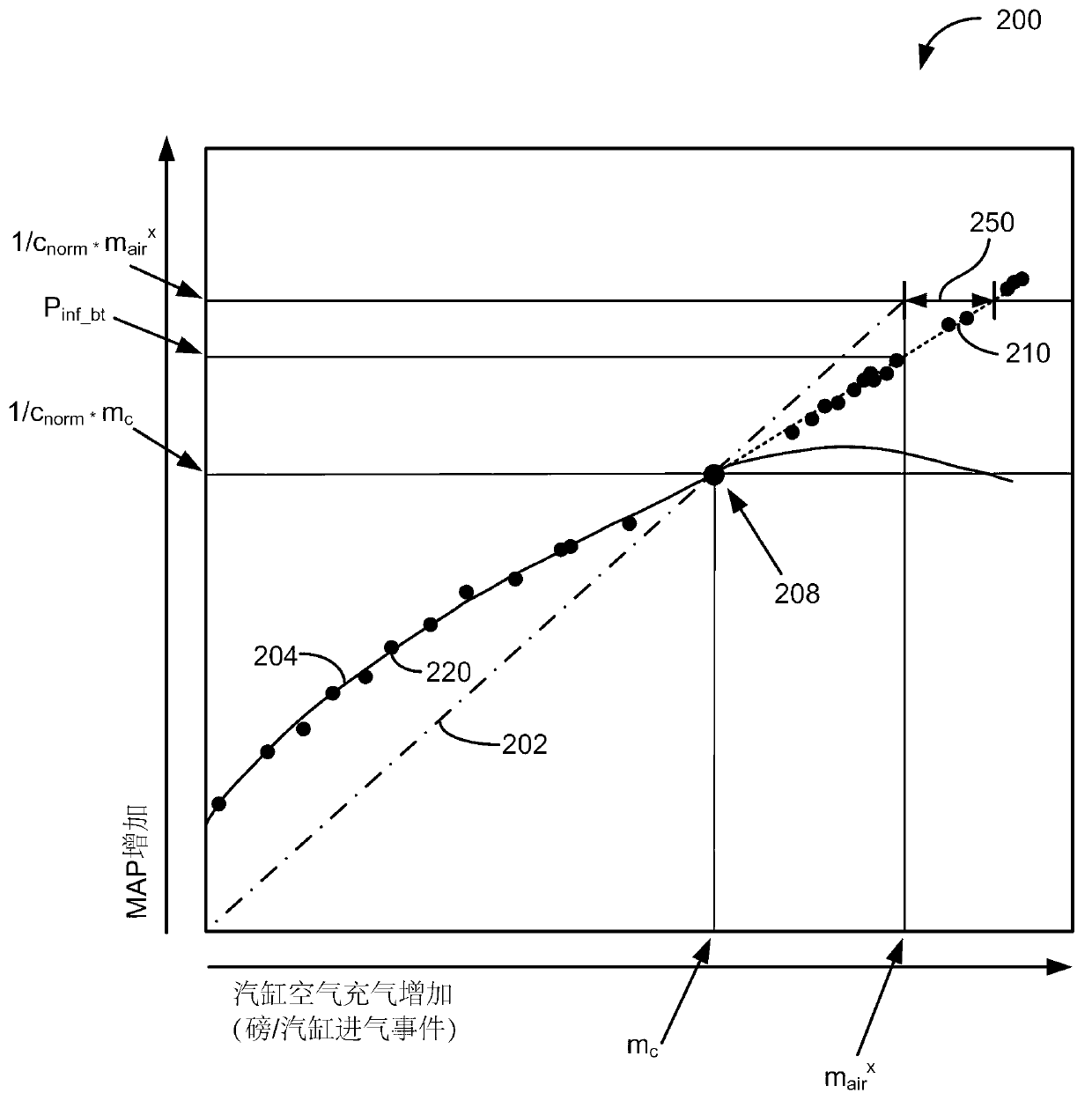

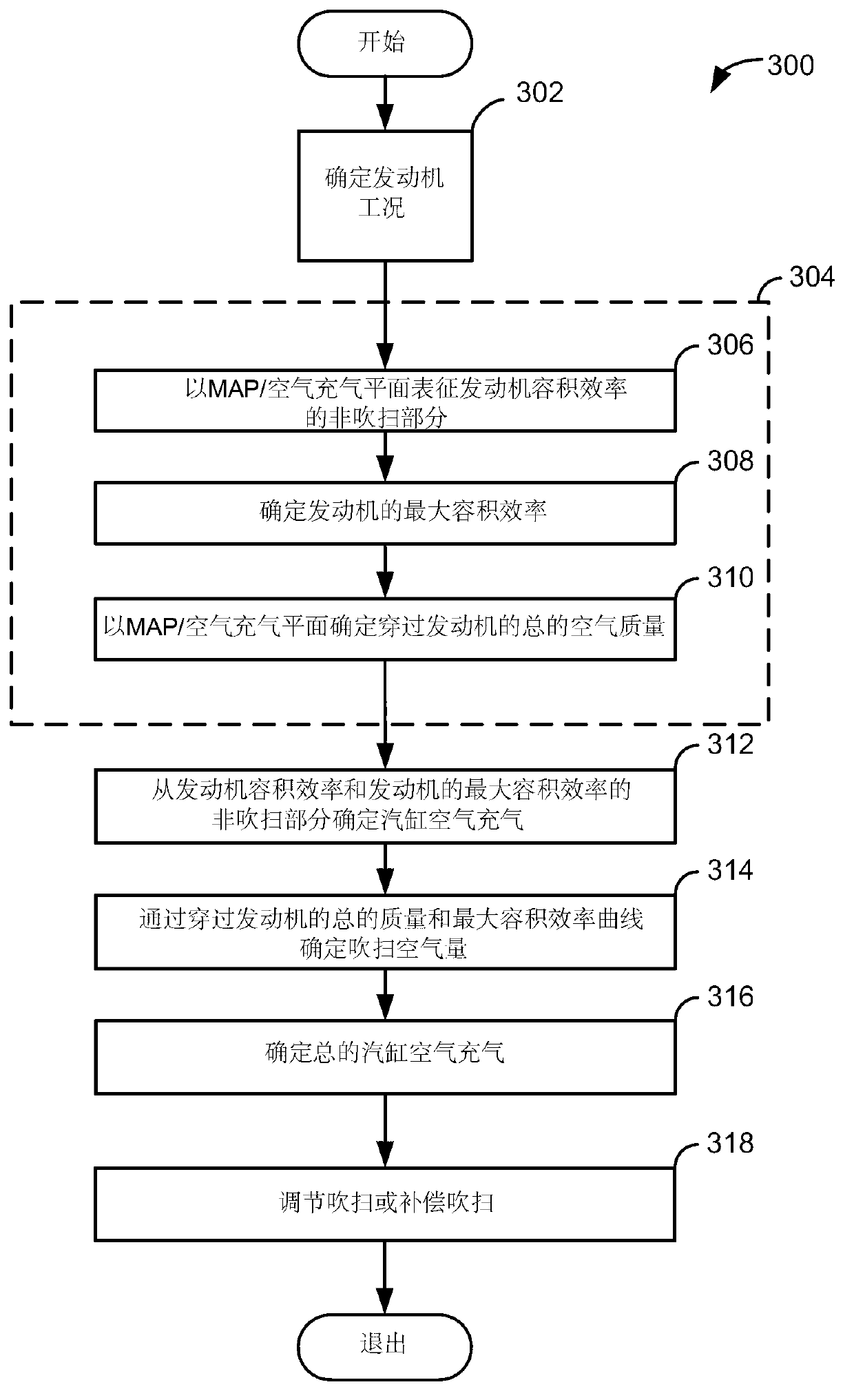

[0014] The purpose of the present invention is to determine the purge of engine cylinders. figure 1 An example system for determining cylinder purge is shown. The system includes a turbocharger that operates with a mixture of spark-ignited air and gasoline, alcohol, or a mixture of gasoline and alcohol. However, in other examples, the engine may be a compression ignition engine, such as a diesel engine. figure 2 A sample graph of the simulation is shown, which is the basis for determining the cylinder purge. image 3 Shows an example method for determining and adjusting cylinder purge.

[0015] reference figure 1 , Through the electronic engine controller 12 control including multiple cylinders ( figure 1 Only one cylinder) of the internal combustion engine 10 is shown. The engine 10 includes a combustion chamber 30 and a cylinder wall 32 in which a piston 36 is located and connected to the crankshaft 40. Combustion chamber 30 is shown as communicating with intake manifold 44 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com