Comprehensive-conventional mechanical mining double-unit face coal mining method under complicated geological conditions

A technology with complex geological conditions and coal mining methods, applied in surface mining, underground mining, earthwork drilling and mining, etc., to achieve the effect of improving the working face environment, simple method, and improving coal mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The present invention comprises the steps:

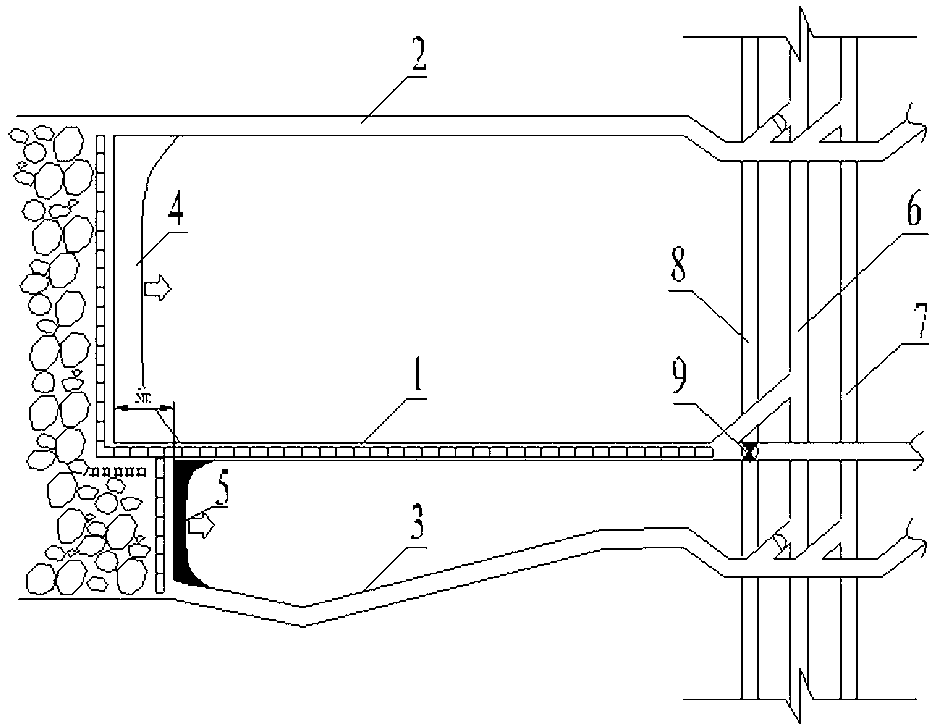

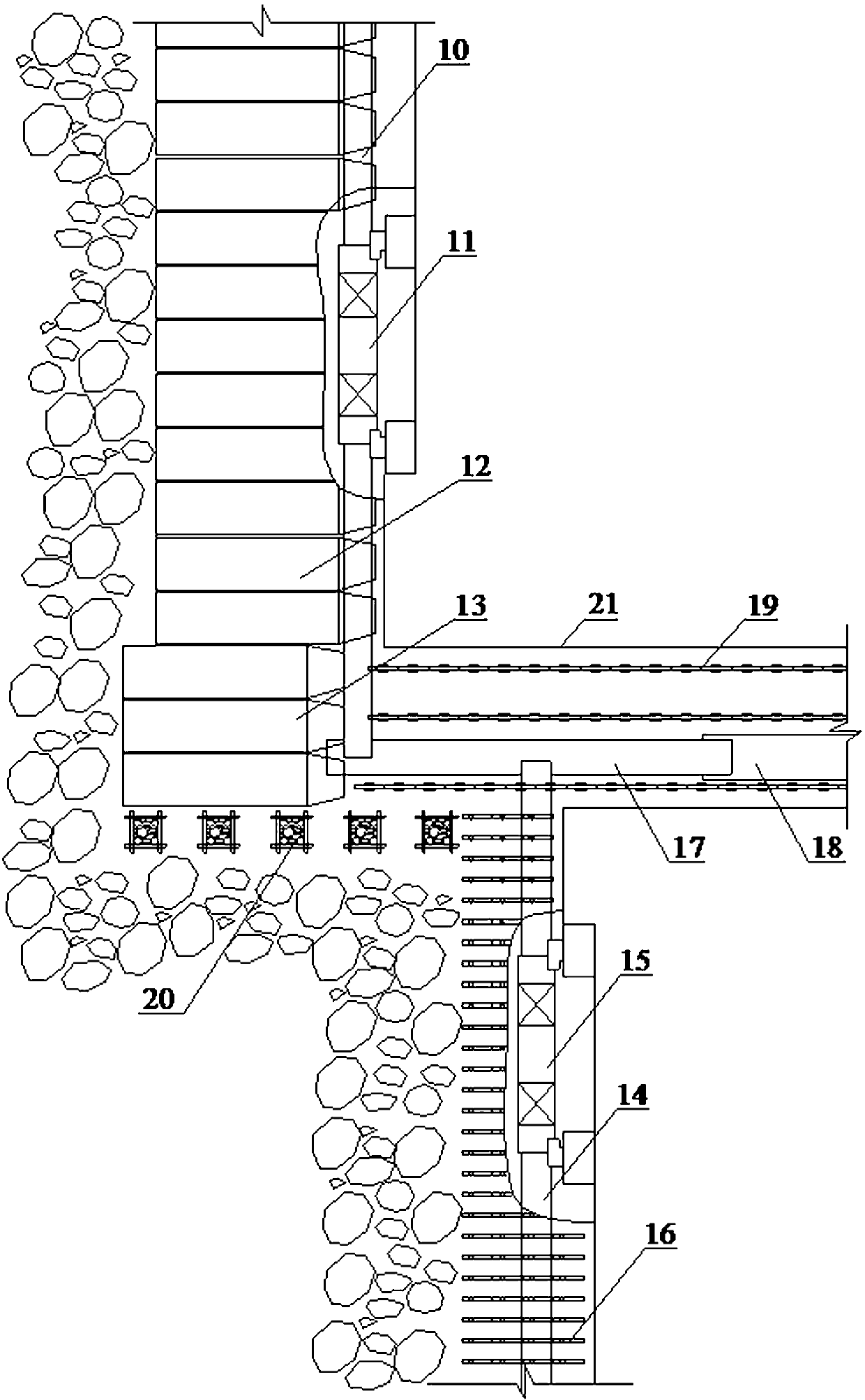

[0018] 1) For the mining of coal resources in irregular sections under complex geological conditions, such as figure 1 , 2 As shown, the upper part of the irregular coal block in the section is arranged according to the same length of the working face 4, and the fully mechanized mining hydraulic support 12 is used to support the recovery space of the working face 4; the lower part of the irregular coal block in the section is arranged as The unequal-length mechanical mining face 5 adopts single hydraulic props and hinged top beams 16 to support the recovery space of the working face 5; Face 5 is ahead of Section 4 of the fully mechanized mining face, and wooden piles 20 are set up on the side of the goaf close to the mechanized mining face 5, and gangue is filled in the middle of the wooden piles 20 to enhance the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com