Mist antistatic agent for release liner

An anti-static agent, anti-static technology, applied in the direction of release paper, no pigment coating, coating, etc., can solve the problems of destroying the purity and consistency of the film, the local unevenness of the release coating layer, and excessive static electricity. , to achieve the effect of improving the anti-static performance of the film surface, improving the anti-static effect, and improving the scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

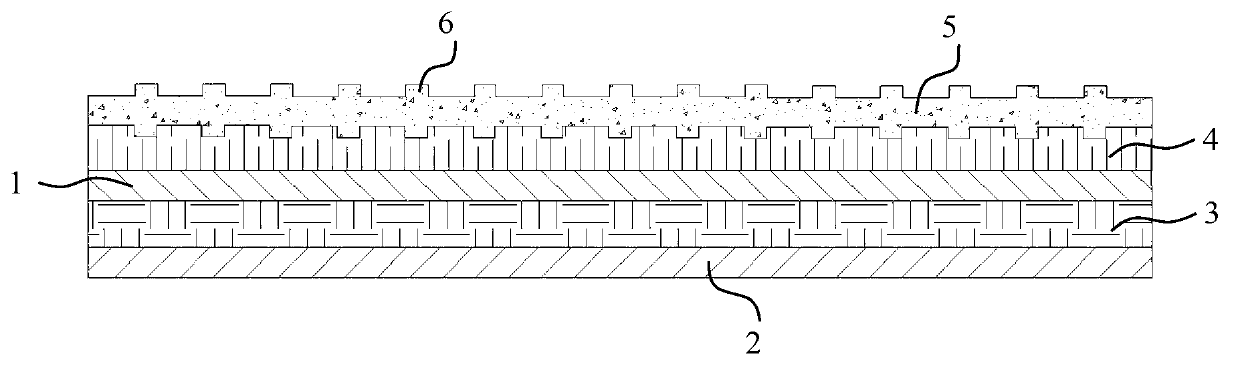

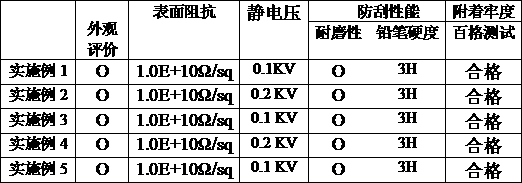

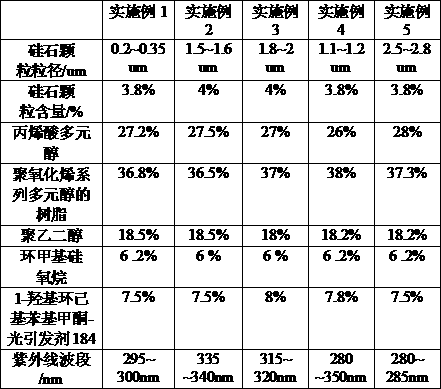

[0024] Embodiments 1 to 5: A matte antistatic agent for a release film, the release film includes a base paper layer 3 coated with a PE film 1 and a PET film 2 on the upper surface and the lower surface respectively, and the base paper layer 3 The other surface of the PET film 2 is coated with a matte antistatic coating 4, and the other surface of the matte antistatic coating 4 is coated with a release agent coating 5; The roughness of the surface contacted by the mold coating 5 is 2.83um-3.32um, and the other surface of the mold release coating 5 has several raised parts 6;

[0025] The matte antistatic coating 5 is coated with a matte antistatic agent, and the matte antistatic agent is composed of the following components in mass percentage:

[0026] Silica particles 3.8~4.2%,

[0027] Acrylic polyol with average molecular weight of 500~2000 26~28%,

[0028] Resin of polyoxyalkylene series polyols with an average molecular weight of 200~2500 36~38%,

[0029] Polyethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com