Preparation method of novel matte anti-static release paper

An anti-static, release paper technology, used in paper, papermaking, paper coatings, etc., can solve the problems of low bonding force between the coating layer and the release agent coating, unstable peeling force, etc. Surface anti-static performance, improve anti-static effect, improve scratch resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

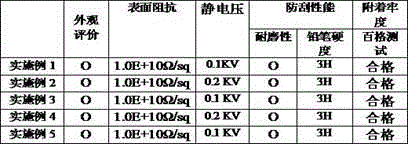

[0028] Embodiment 1~5: a kind of preparation method of novel matte surface antistatic release paper mainly consists of the following steps:

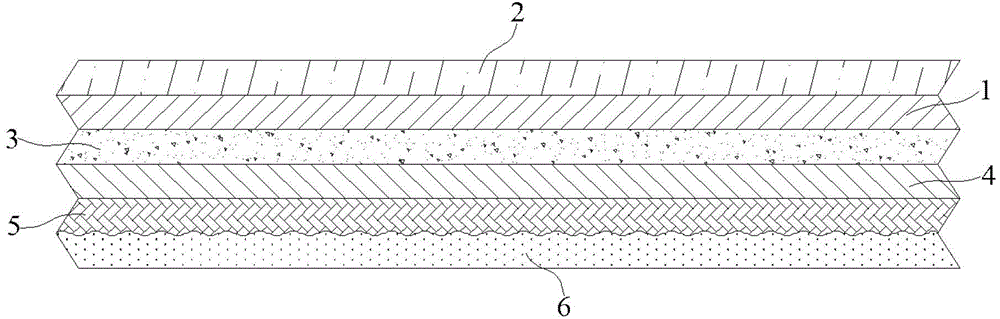

[0029] Step 1. Use a laminating machine to coat a film layer 2 on one surface of a release paper base paper 1. After the film layer 2 is cooled, apply an adhesive layer on the other surface of the release paper base paper 1 3 to obtain the substrate layer;

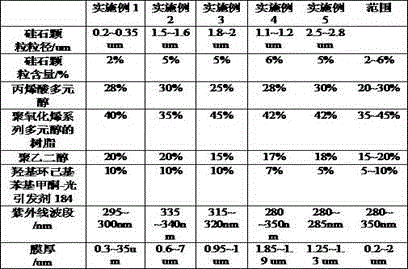

[0030] Step 2, coating a layer of matte antistatic coating 5 with a thickness of 0.2 to 2 microns on one surface of a film layer 4, the matte antistatic coating 5 is composed of the following components in mass percentage:

[0031] Silica particles 2~6%,

[0032] Acrylic polyols with an average molecular weight of 500~2000 20~30%,

[0033] Polyoxyalkylene series polyol resin with an average molecular weight of 200~2500 35~45%,

[0034] Polyethylene glycol 15~20%,

[0035] 1-Hydroxycyclohexyl phenyl ketone-photoinitiator 184 5~10%;

[0036] The particle size of the silica particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com