PTFE (polytetrafluoroethylene) base material with high filler content and preparation and application thereof

A high filler and content technology, applied in chemical instruments and methods, circuit substrate materials, layered products, etc., can solve the problems of complex process, large waste water, high water absorption rate of plates, etc., achieve excellent comprehensive performance, solve complex process, The effect of water absorption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

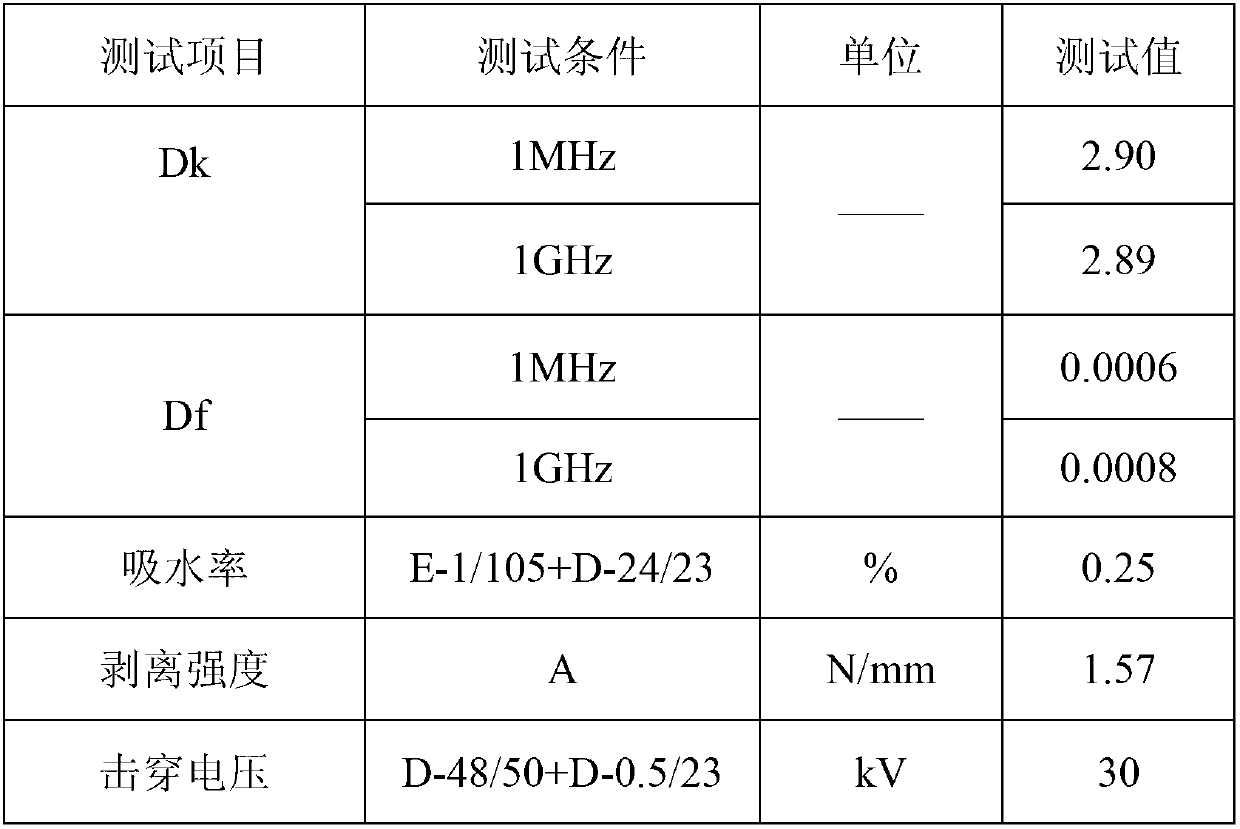

Embodiment 1

[0080] PTFE resin powder with a particle size of about 38 μm, produced by Daikin Corporation of Japan.

[0081] Composition ratio of fluororesin dispersion emulsion: 100g of PTFE emulsion, 10g of PFA emulsion, 10g of FEP emulsion, appropriate amount of deionized water, and adjust the solid content to 50%. The emulsions are all produced by Daikin Corporation of Japan.

[0082] Inorganic filler: microsilica powder, particle size about 2~10μm, Donghai Microsilica Powder Factory.

[0083] Lubricant, DPG, commercially available.

[0084] Take 1000g of the above PTFE resin powder, add 1000g of silicon micropowder, stir and mix in a high-speed mixer for about 1 hour, then add 300g of lubricant DPG, mix at a slow speed for 20 minutes, send the mixture to the extruder, and extrude it into a diameter of about 5mm rods, the rods are then rolled several times to finally obtain a sheet with a size of 300×300×1.0mm, and the sheet is heat-treated at 300°C / 120 minutes, and after cooling, im...

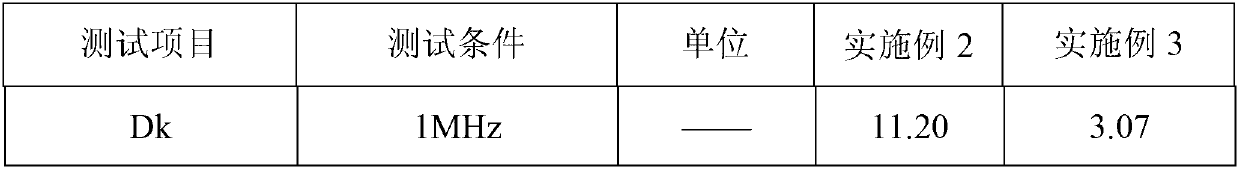

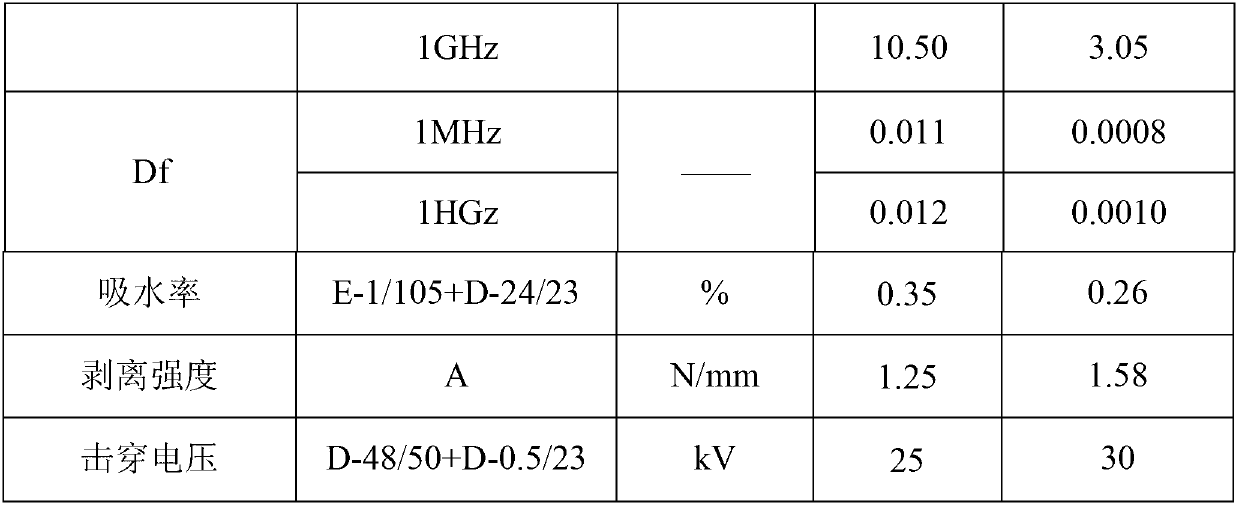

Embodiment 2

[0088] PTFE resin powder, particle size about 50μm.

[0089] Composition ratio of fluororesin dispersion emulsion: 100g of PTFE emulsion, 10g of PFA emulsion, 10g of FEP emulsion, appropriate amount of deionized water, and adjust the solid content to 50%. The emulsions are all produced by Daikin Corporation of Japan.

[0090] Inorganic filler: titanium dioxide, particle size about 20μm.

[0091] Lubricant, DOP, commercially available.

[0092] Take 800g of the above PTFE powder, add 1200g of titanium dioxide, stir and mix in a high-speed mixer for about 0.5 hours, then add 300g of lubricant DOG, mix at a slow speed for 20 minutes, send the mixture to the extruder, and extrude it into a diameter of about 5mm. Rod, the rod is then rolled several times to finally obtain a sheet with a size of 300×300×1.0mm. The sheet is heat-treated at 350°C / 60 minutes. After cooling, immerse in the above-mentioned fluororesin fractional emulsion for 2 minutes , take it out and put it into an ...

Embodiment 3

[0094] PTFE resin powder with a particle size of about 15 μm, produced by Daikin Corporation of Japan.

[0095] Composition ratio of fluororesin dispersion emulsion: PTFE emulsion 100g, appropriate amount of deionized water, adjust the solid content to 50%. The emulsion was produced by Daikin Corporation of Japan.

[0096] Inorganic filler: silicon dioxide, particle size about 10 μm, Donghai Silica Powder Factory.

[0097] Lubricant, PIB, commercially available.

[0098] Take 800g of the above PTFE powder, add 1200g of silicon micropowder, stir and mix in a high-speed mixer for about 1.5 hours, then add 300g of lubricant PIB, mix at a slow speed for 20 minutes, send the mixture to the extruder, and extrude it into a diameter of about 5mm The rod is then rolled several times to finally obtain a sheet with a size of 300×300×1.0 mm. The sheet is heat-treated at 250°C / 360 minutes. After cooling, it is immersed in the above-mentioned fluororesin fractional emulsion 7 minutes, ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com