Preparation method of novel insulated rubber

An insulating rubber, a new type of technology, applied in the field of rubber materials, can solve the problems of low strength of pure rubber, intolerance to tearing, low insulation resistivity, etc., to achieve good interface adhesion, increase production costs, and improve the effects of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

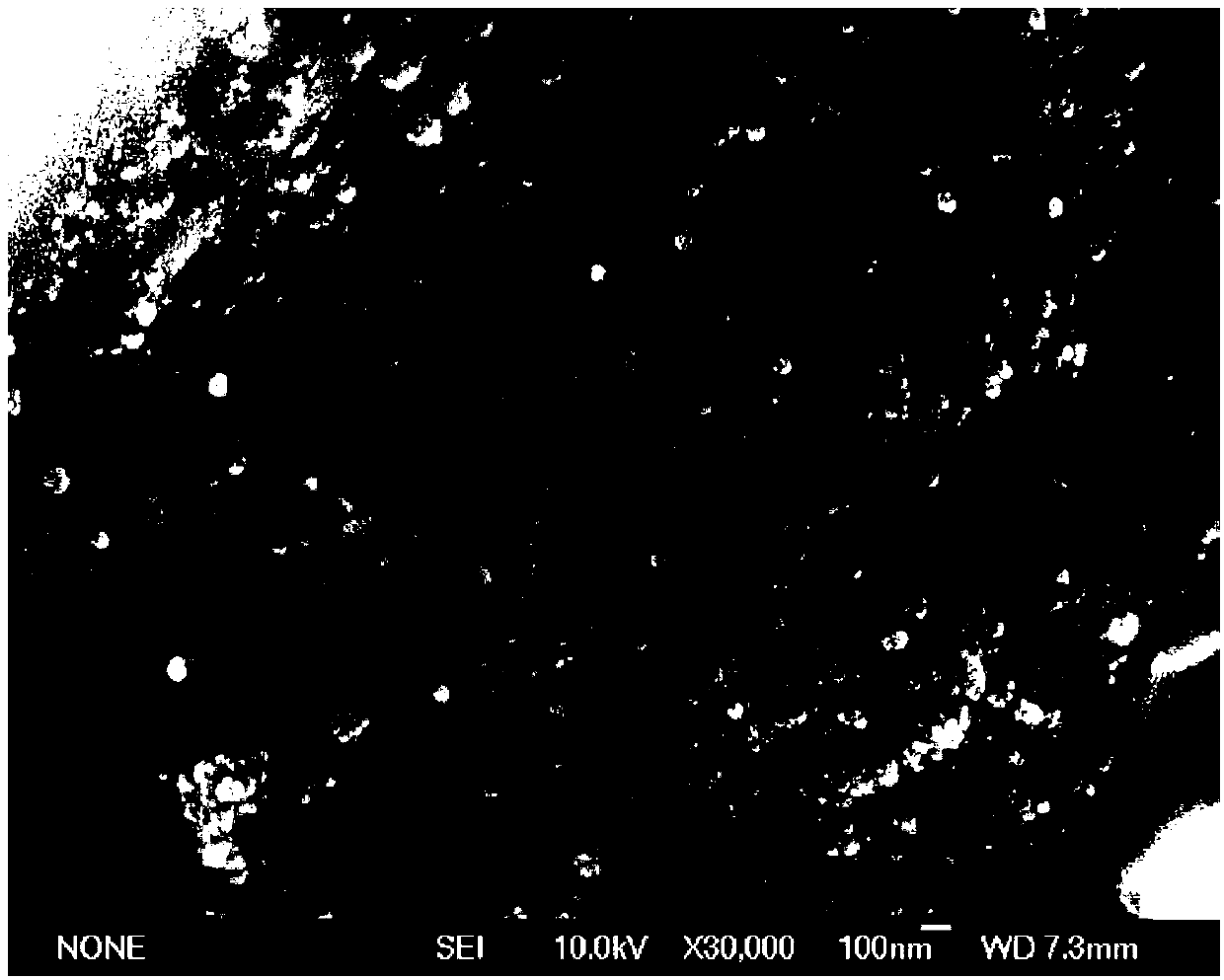

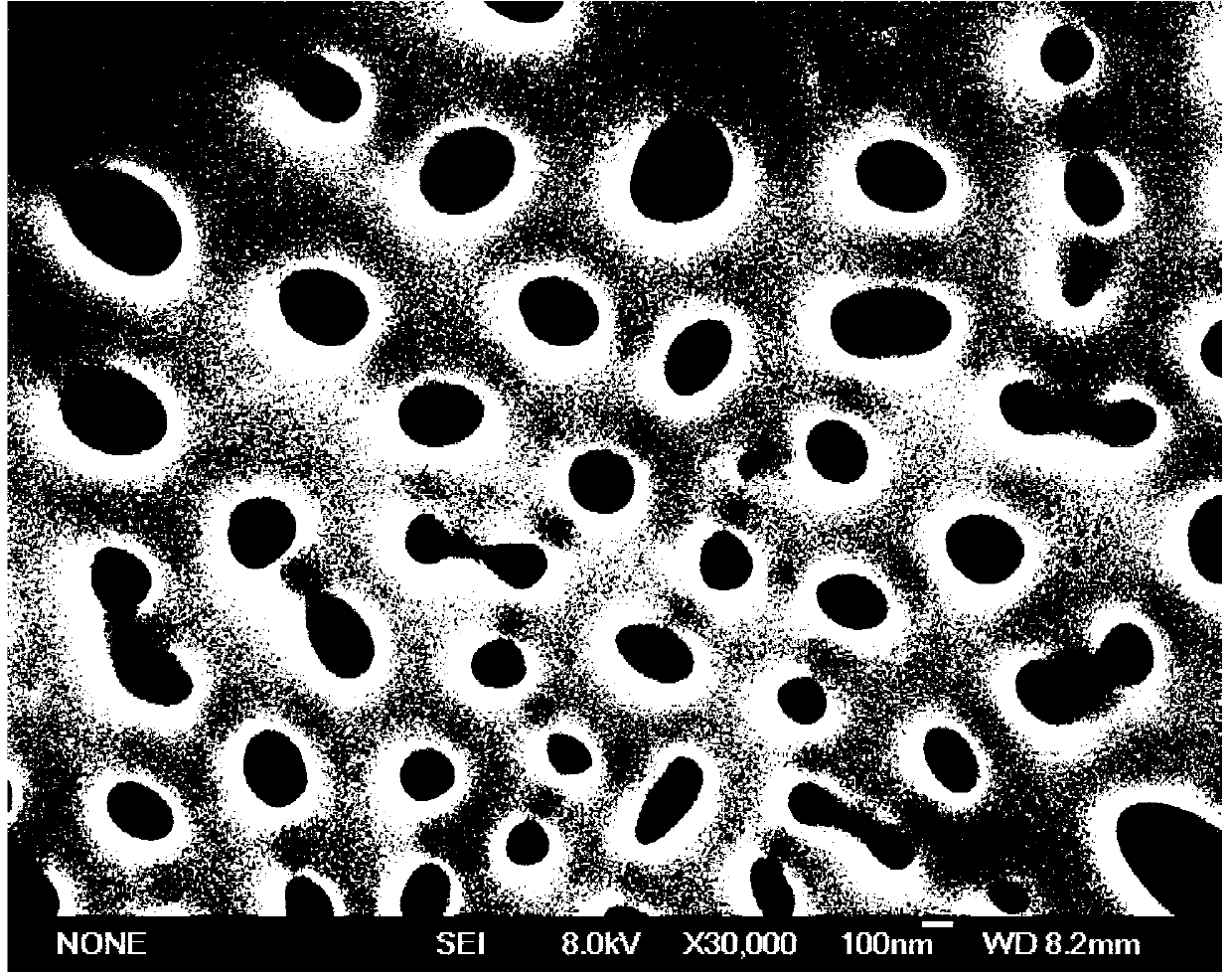

Image

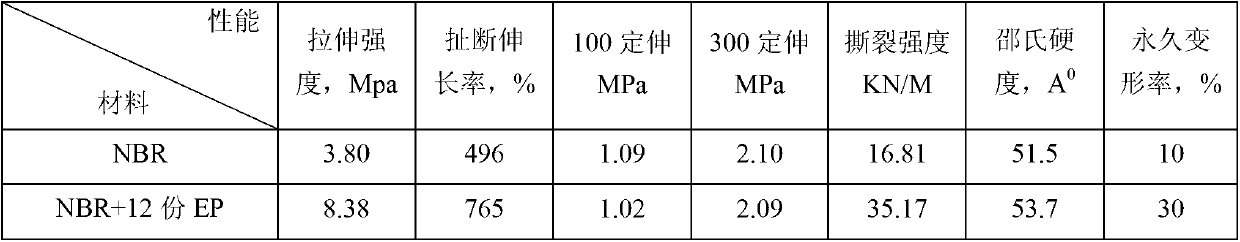

Examples

Embodiment 1

[0025] A preparation method of liquid oligomer modified insulating rubber, comprising the following sequential steps:

[0026] (1) Weigh 100 parts of nitrile rubber (model NBR-41), 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide (promoting CZ), 5 parts of zinc oxide (ZnO), stearin 2 parts of acid (SA), 1 part of dihydroquinoline polymer (anti-RD), 0.5 parts of tetramethylthiuram disulfide (promoting TMT D), 1.5 parts of sulfur (S), bisphenol A liquid epoxy Resin (EP) 12 parts, epoxy resin curing agent 6 parts.

[0027] (2) Add nitrile rubber, CZ, ZnO, SA, and RD1 in turn on the double-roll mill with the roll temperature at 40-50°C, and mix the above-mentioned raw materials evenly after mixing for 4-8 minutes. .

[0028] (3) Stir the liquid epoxy resin and its curing agent evenly with a stirring rod.

[0029] (4) Add the mixture in (3) to the rubber compound in (2) and knead for 4-8min, add TMTD and S after kneading evenly, and then knead for 4-6min before taking off t...

Embodiment 2

[0039] A preparation method of liquid oligomer modified insulating rubber, comprising the following sequential steps:

[0040] (1) Weigh 100 parts of chloroprene rubber (CR), 4 parts of magnesium oxide (MgO), 5 parts of ZnO, 0.5 parts of SA, and 8 parts of liquid phenolic resin (PF).

[0041] (2) Add neoprene, MgO, ZnO, and SA in turn on a double-roll mill with the roll temperature at 40-50°C, and mix the above-mentioned raw materials evenly after mixing for 4-8 minutes.

[0042] (3) Add the liquid phenolic resin to the compounded compound in (2), mix for 4-8 minutes, then release the film, and store it for more than 8 hours for later use.

[0043] (4) On the flat vulcanizer, vulcanize the material mixed in (3), the conditions for vulcanization:

[0044] 150°C×20min, the pressure is 15MPa.

[0045] (5) Take out the sample in (4), punch out the sample according to the national standard, and test various performance indicators of the composite system according to the national ...

Embodiment 3

[0054] A preparation method of liquid oligomer modified insulating rubber, comprising the following sequential steps:

[0055] (1) 100 parts of ethylene-propylene rubber (brand EP-33), 5 parts of ZnO, 1 part of SA, 1 part of anti-RD, 0.5 parts of mercaptobenzothiazole (promoting M), 0.5 parts of paraffin, 1.5 parts of promoting TMTD, S1.5 parts, liquid phenolic resin (PF) 12 parts.

[0056] (2) On the double-roll mill, under the condition that the roll temperature is 60-80°C, add ethylene-propylene rubber, ZnO, SA, anti-RD, M-promoting, paraffin in turn, and after mixing for 4-8min, mix the above raw materials well mixed.

[0057] (3) Add liquid phenolic resin to the mixed material in (2) and knead for 4-8 minutes.

[0058] (4) Add the material mixed in (3) to promote TMTD and S, mix evenly, and then release the tablet, and park it for more than 8 hours for later use.

[0059] (5) On a flat vulcanizer, vulcanize the material mixed in (4), vulcanization conditions: 160°C × 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com