Microcrystal glass ceramic tile and production method for reducing air bubbles

A technology of glass-ceramic and production method, applied in the field of micro-crystal manufacturing, can solve problems affecting product quality, etc., and achieve the effects of reducing bubbles, improving product quality, and small bubble volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

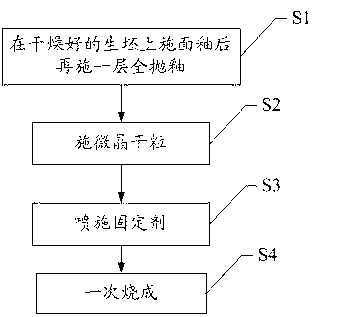

[0054] A production method for reducing air bubbles in glass-ceramic tiles, comprising the following steps:

[0055] S1. After applying the surface glaze on the dried green body, apply a layer of full glaze. The application amount of the surface glaze is 700g on the green body of 800*800mm, and the specific gravity is 1.8. The application amount of the full glaze is 200g on the green body of 800*800mm, and the specific gravity is 1.35.

[0056] S2, applying microcrystalline dry granules, the sieved mesh number of the microcrystalline dry granules is 10-80 mesh, and the microcrystalline dry granules include in weight percentage:

[0057] 10-30 mesh 45%;

[0058] 30-60 mesh 35%;

[0059] 60-80 mesh 20%.

[0060] The application amount of the microcrystalline dry granules is 3000g on a green body of 800*800mm, and the raw materials for preparing the microcrystalline dry granules include by weight percentage:

[0062] Aluminum oxide 15%;

[0063] ...

Embodiment 2

[0073] A production method for reducing air bubbles in glass-ceramic tiles, comprising the following steps:

[0074] S1. After applying the surface glaze on the dried green body, apply a layer of full glaze. The application amount of the surface glaze is 650g on the green body of 800*800mm, and the specific gravity is 1.75. The application amount of the full glaze is 150g on the green body of 800*800mm, and the specific gravity is 1.3.

[0075] S2, applying microcrystalline dry granules, the sieved mesh number of the microcrystalline dry granules is 10-80 mesh, and the microcrystalline dry granules include in weight percentage:

[0076] 10-30 mesh 40%;

[0077] 30-60 mesh 35%;

[0078] 60-80 mesh 25%.

[0079] The application amount of the microcrystalline dry granules is 3500g on the green body of 800*800mm, and the raw materials used to prepare the microcrystalline dry granules include by weight percentage:

[0081] Aluminum oxide 17%;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com