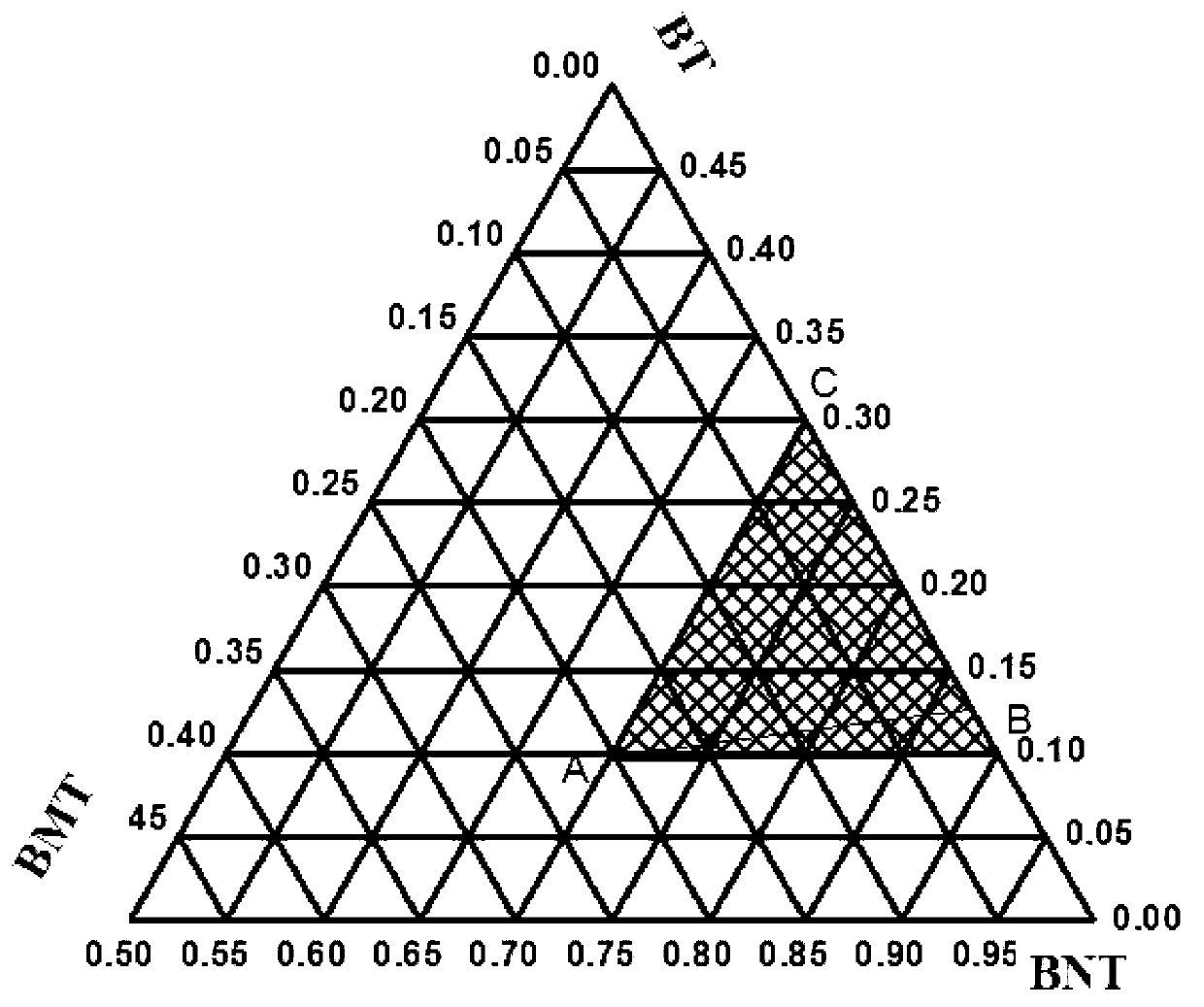

Bi0.5Na0.5TiO3-BaTiO3-BiMg0.5Ti0.5O3 lead-free piezoelectric ceramic material

A technology of BNT-BT-BMT and ceramic materials, applied in the field of perovskite structure piezoelectric ceramics, can solve the problems of low piezoelectric activity, difficulty in polarization, large coercive field, etc., and achieve various performance improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

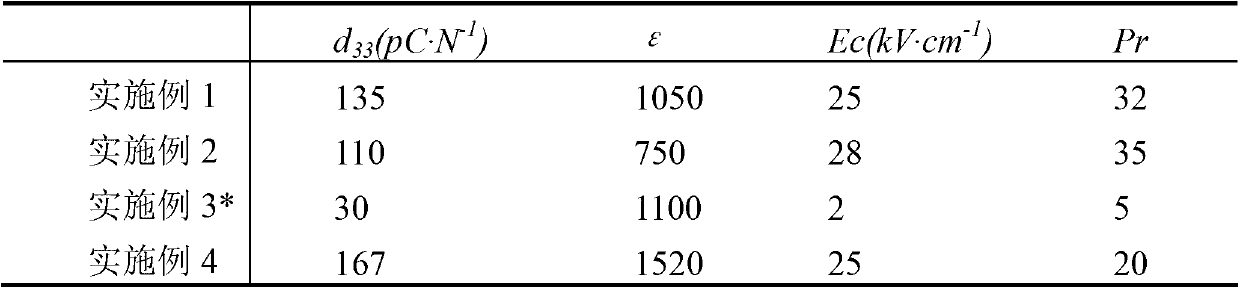

Embodiment 1

[0020] Recipe:

[0021] 0.9Bi 0.5 Na 0.5 TiO 3 -0.1BaTiO 3 -0BiMg 0.5 Ti 0.5 o 3

[0022] Process: calcination temperature 850°C, sintering temperature 1200°C.

Embodiment 2

[0024] Recipe:

[0025] 0.7Bi 0.5 Na 0.5 TiO 3 -0.30BaTiO 3 -0BiMg 0.5 Ti 0.5 o 3

[0026] Process: calcination temperature 900°C, sintering temperature 1100°C.

Embodiment 3

[0028] Recipe:

[0029] 0.7Bi 0.5 Na 0.5 TiO 3 -0.1BaTiO 3 -0.2BiMg 0.5 Ti 0.5 o 3

[0030] Process: calcination temperature 850°C, sintering temperature 1150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com