Method for preparing ZSM-22 molecular sieve by using seed crystal synthesis method

A technology of molecular sieve and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of ZSM-22 that have not been reported, and achieve the effects of shortening the crystallization time, good catalytic activity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: synthetic ZSM-22 seed crystal

[0020] First, 10.4g H 2 O mixed with 0.07g aluminum sulfate, then added 0.22g KOH to it, stirred and clarified, added 0.43g 1,6-hexanediamine (DAH), then added 3g tetraethyl orthosilicate (TEOS) under stirring, continued After stirring until the solution became uniform, the reaction raw materials were added to a polytetrafluoroethylene stainless steel dynamic tank, the dynamic kettle speed was 30 rpm, crystallization was complete at 160°C for 34 hours, the product was suction filtered, and dried to obtain the product.

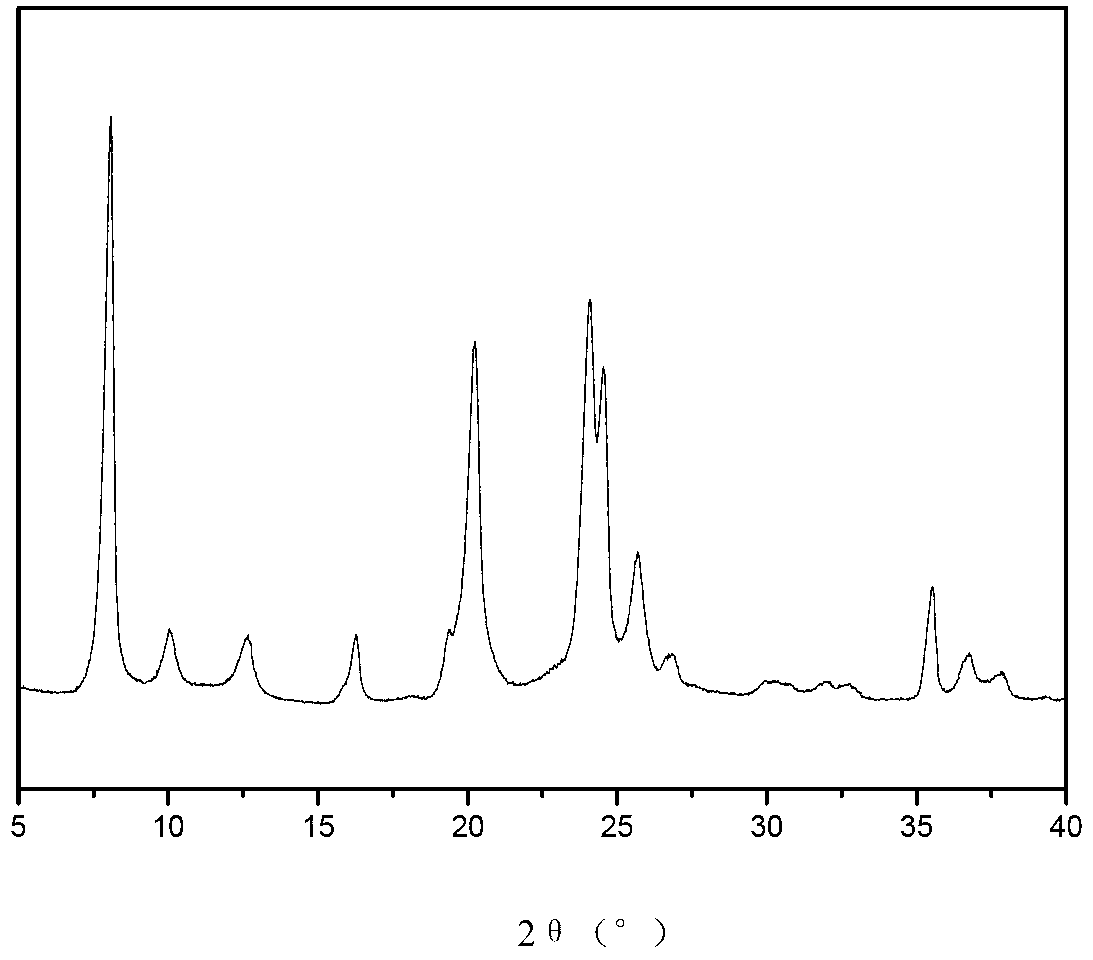

[0021] Its structure is ZSM-22 zeolite molecular sieve through X-ray diffraction analysis, and it can be seen from scanning electron microscope photos that the product obtained by the seed crystal method has high purity.

[0022] attached figure 1 It is the scanning electron microscope photo (SEM) of the synthesized seed crystal. From the photo, we can see some rod-shaped or needle-shaped products, which sh...

Embodiment 2

[0023] Embodiment 2: The impact of crystallization time on ZSM-22 prepared by seed crystal method

[0024] First, 17g H 2 O and 0.192g of aluminum sulfate were mixed evenly, and then 0.209g of KOH was added to it, and after stirring and clarification, 3g of tetraethyl orthosilicate (TEOS) was added, and the stirring was continued until the solution became uniform, and 5% ZSM-22 molecular sieve was added as a seed crystal ( The amount of seed crystals is represented by input SiO 2 mass percent calculation). Then the reaction raw materials were added into a polytetrafluoroethylene stainless steel reaction kettle, the dynamic kettle rotation speed was 30rpm, crystallized at 140°C for 0.5-5 days respectively, the product was suction filtered, and the product was obtained after drying.

[0025] It can be found that ZSM-22 containing a lot of amorphous is obtained when crystallization is 0.5 days and 1 day; substantially pure ZSM-22 is obtained when crystallization is 1.5 days; ZS...

Embodiment 4

[0030] Example 4: Substituting NaOH for KOH as alkali source

[0031] First, 11.5g H 2 O and 0.096g of aluminum sulfate are mixed evenly, then 0.18g of NaOH is added to it, after stirring and clarification, 3g of tetraethyl orthosilicate (TEOS) is added, and the stirring is continued until the solution becomes uniform, then 5% ZSM-22 molecular sieve is added as a seed crystal (crystal The amount of seed is represented by input SiO 2 mass percent calculation). Then the reaction raw materials were added into a polytetrafluoroethylene stainless steel reaction kettle, the dynamic kettle speed was 30rpm, the crystallization was completed at 140°C for 2 days, and the product was suction filtered and dried to obtain ZSM-22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com