Roll-forming method of GH4648 high temperature alloy complex deformed section ring unit

A special-shaped cross-section, high-temperature alloy technology, applied in the field of rolling and forming of ring parts, can solve the problems of unfavorable precision rolling and forming of special-shaped cross-section ring parts, scrapping of ring parts, unsatisfactory cross-section contour, etc. The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] The main chemical element content (percentage by weight) of the GH4648 superalloy given in the prior art is: C content≤0.10%, Cr content 32.0%~35.0%, W content 4.30%~5.30%, Mo content 2.30% %~3.30%, Al content 0.50%~1.10%, Ti content 0.50%~1.10%, Fe content≤4.0, Nb content 0.50%~1.10%, B content<0.008%, Ce content<0.03 %, Mn content<0.40%, S content<0.010%, Si content<0.40%, P content<0.015%, and the balance is Ni.

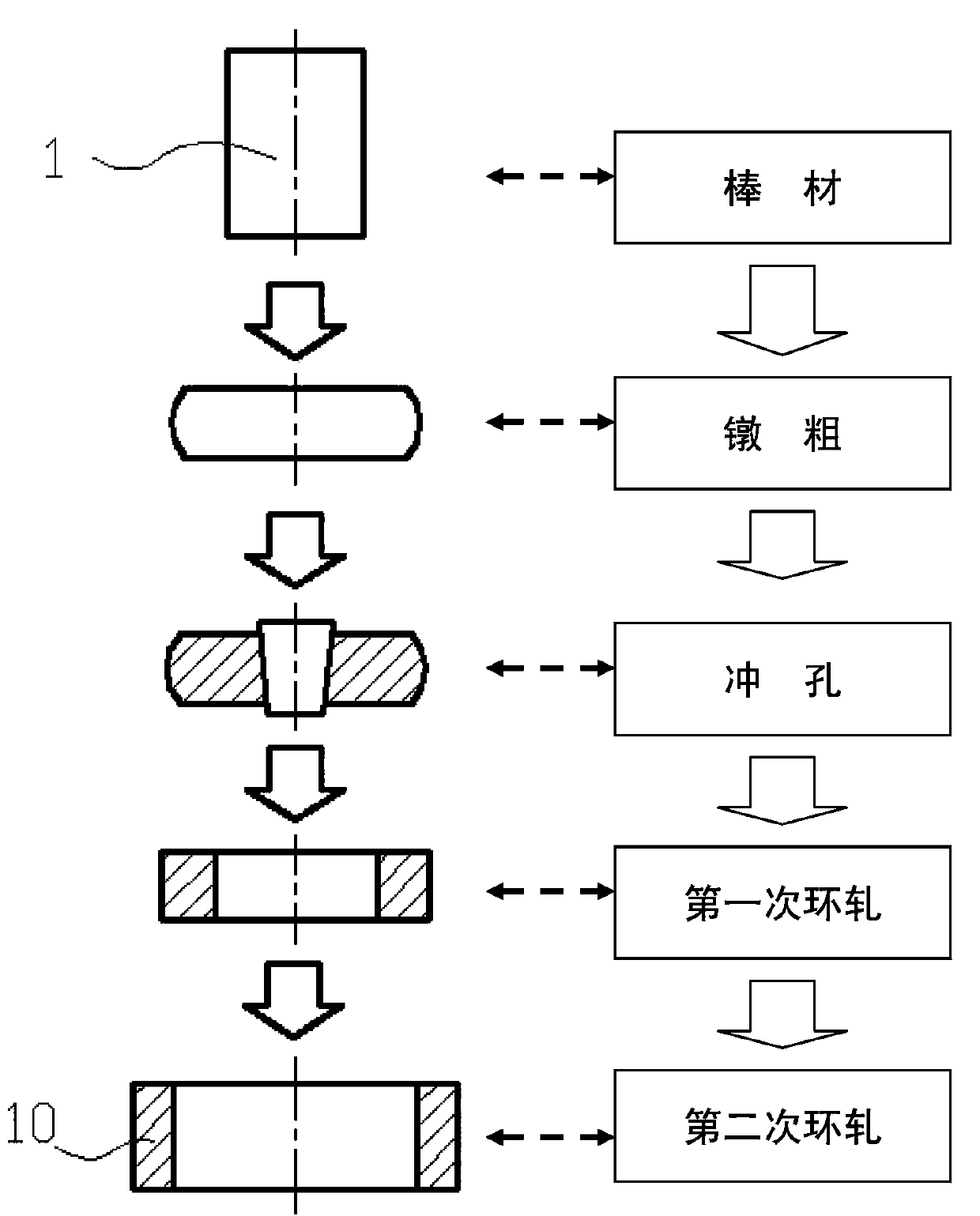

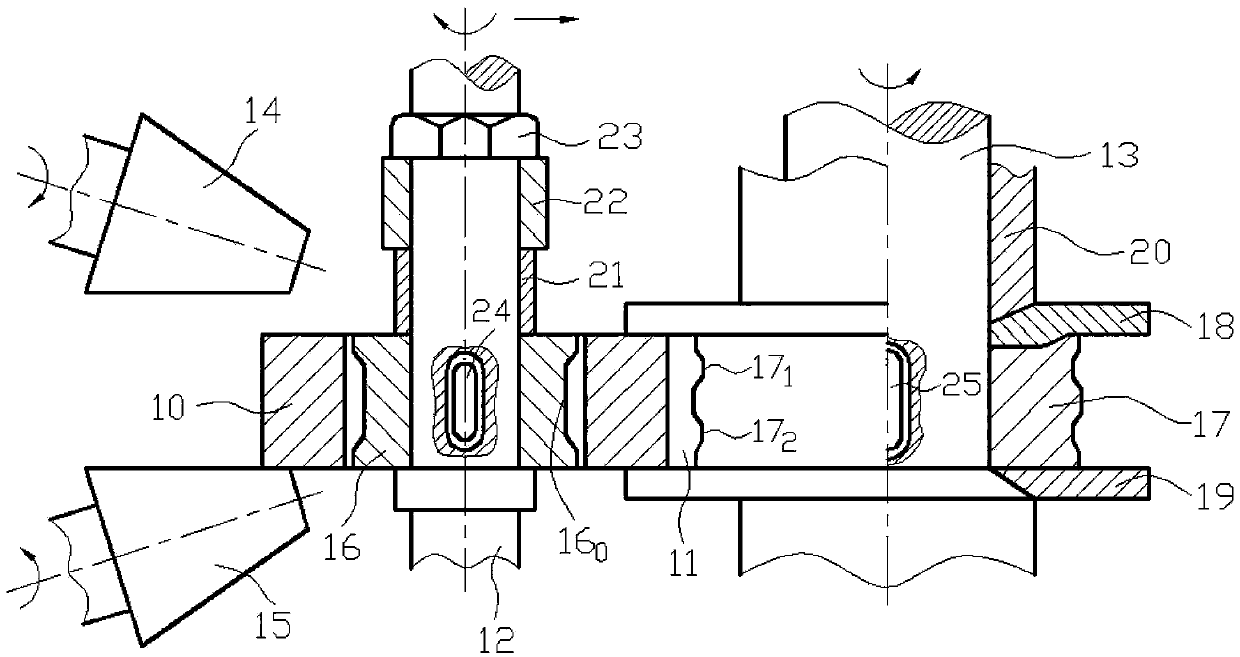

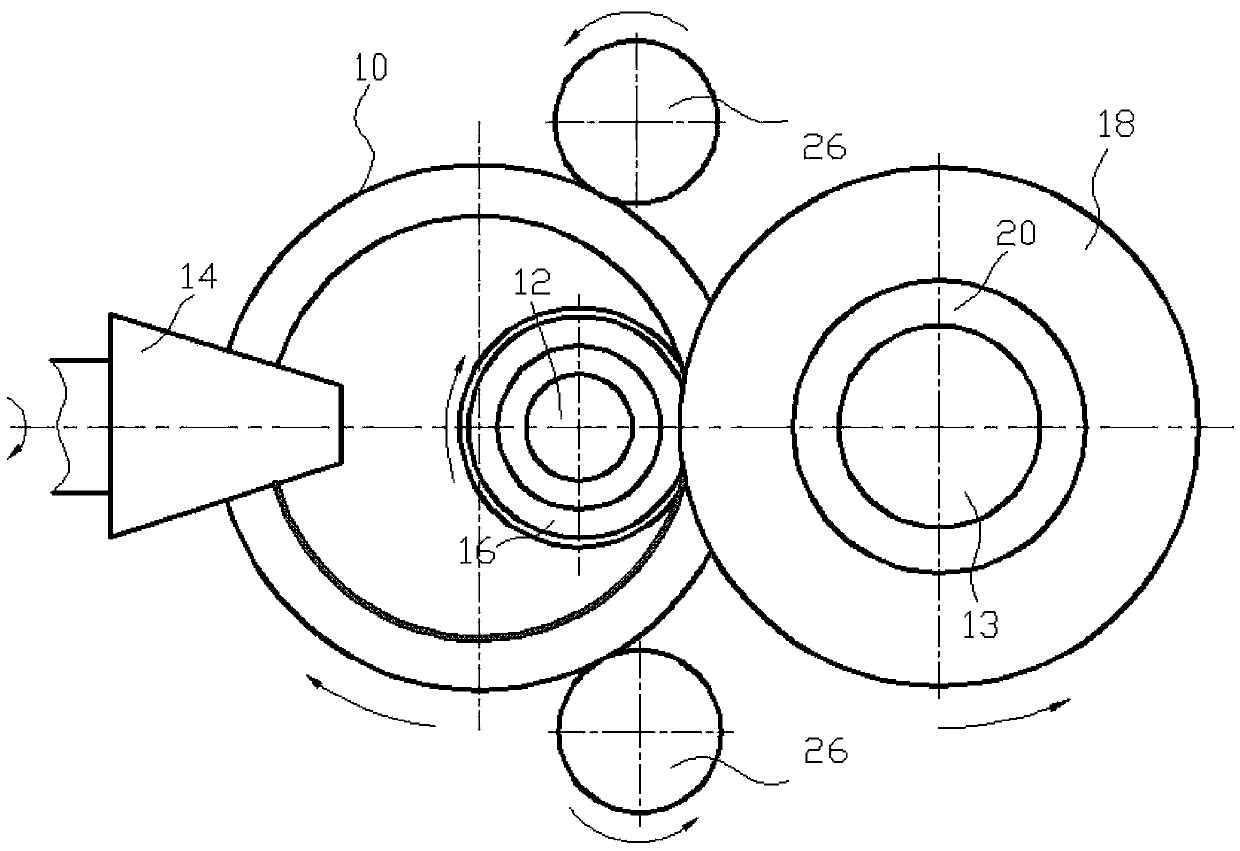

[0043] The process steps of the high-temperature alloy from the bar to the production of qualified ring parts with complex special-shaped cross-sections are as follows:

[0044] Step 1: Billet making of a rectangular pre-rolled billet.

[0045] The billet making of the rectangular pre-rolled billet given in the prior art is as figure 1 As shown, the GH4648 superalloy bar 1 blanked according to the specification is heated to the deformation temperature of 950 ° C ~ 1140 ° C in the forging heating furnace, and is formed into a rectangular pre-rolled billet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com