Rolling forming method of gh4169 superalloy ring with complex special-shaped cross-section

A technology of GH4169 and superalloy, which is applied in the field of rolling forming of ring parts, can solve the problems that are not conducive to the precision rolling forming of ring parts with special-shaped cross-sections, the scrapping of ring parts, and the complexity of the interface, so as to simplify the relationship between the interface and increase the The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] The main chemical element content (percentage by weight) of the GH4169 superalloy given in the prior art is: Cr content 17.0%-21.0%, Ni content 50.0%-55.0%, Mo content 2.80%-3.30%, Ti content 0.75% to 1.15%, Al content 0.30% to 0.70%, C content ≤ 0.08%, Co content ≤ 1.0%, in addition to other trace elements, the balance is Fe.

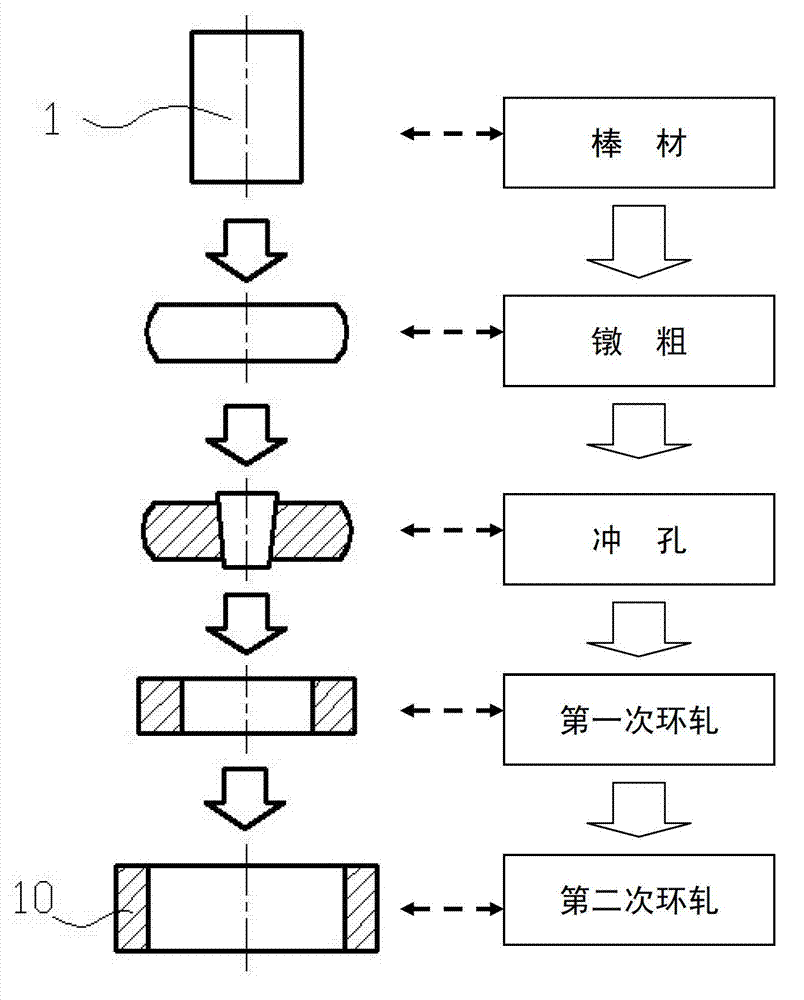

[0043] The process steps of the high-temperature alloy from the bar to the production of qualified ring parts with complex special-shaped cross-sections are as follows:

[0044] Step 1: Billet making of a rectangular pre-rolled billet.

[0045] The billet making of the rectangular pre-rolled billet given in the prior art is as figure 1 As shown, the GH4169 superalloy bar 1 blanked according to the specification is heated to the deformation temperature of 1000 ℃ ~ 1050 ℃ in the forging heating furnace, and is formed into a rectangular pre-rolled billet through upsetting, punching and two times of small deformation ring rolling. 10.

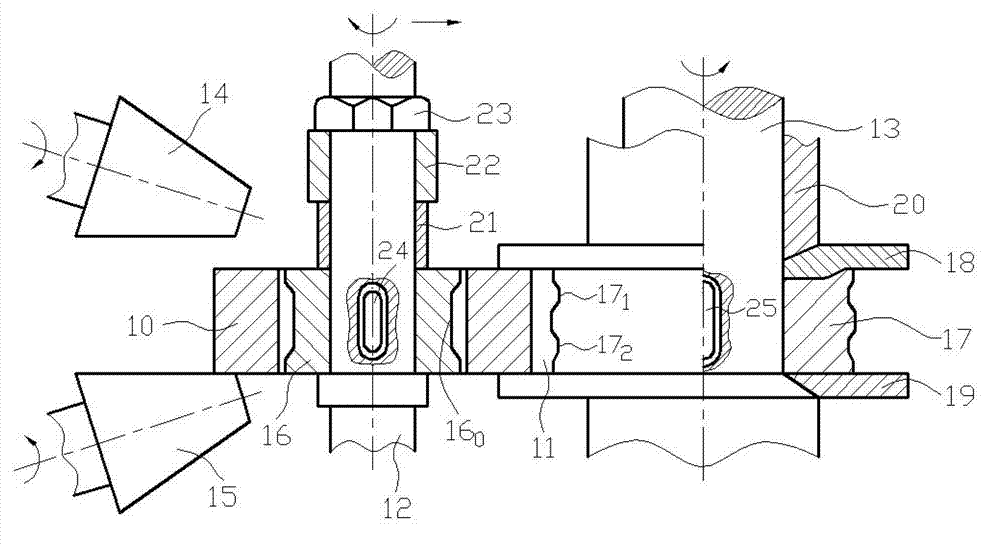

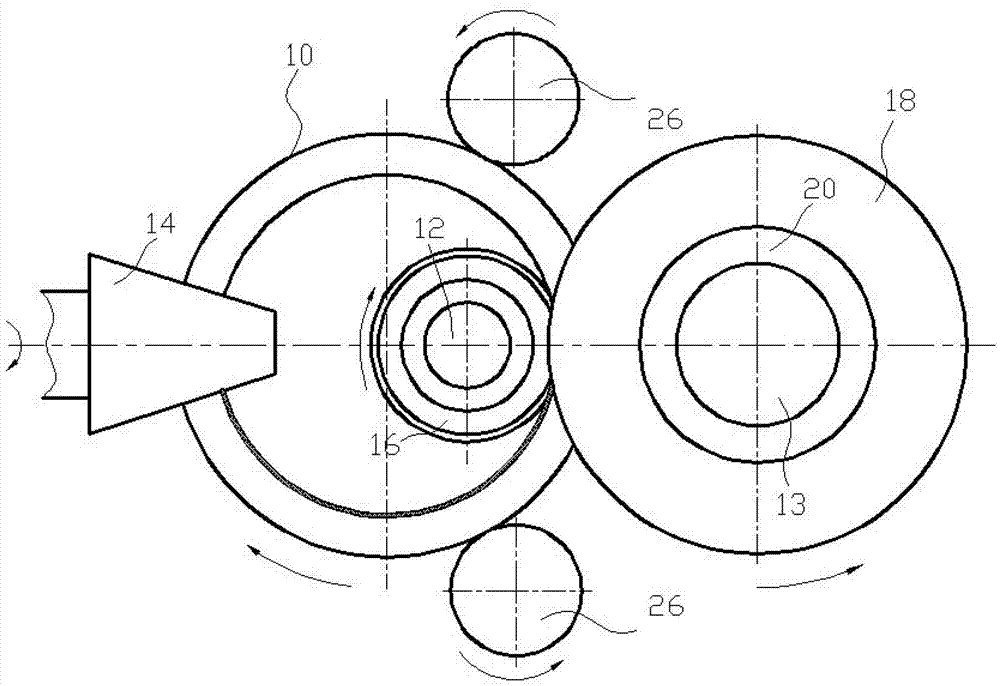

[0046] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com