Isothermal extrusion method capable of controlling speed by sections

A technology of isothermal extrusion and subsection control, applied in the field of warm extrusion, it can solve the problems of difficult control operation and failure to consider engineering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

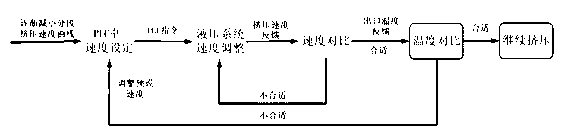

[0018] The isothermal extrusion method of speed segmental control is realized by a double closed-loop control system of speed and temperature. It uses a PLC logic controller as the hardware core. The PLC logic controller is connected to the hydraulic system of the extrusion machine, and the PLC The program is programmed into the logic controller; at the same time, a displacement / speed sensor and a non-contact reflective multi-wavelength infrared thermometer are set on the extruder. Both the displacement / speed sensor and the thermometer are connected to the PLC controller, and the displacement / speed sensor It is used to detect the movement of the extruder, and the thermometer is used to detect the temperature change of the extruded die mouth.

[0019] Such as figure 1 As shown, the specific implementation steps of this isothermal extrusion method with segmental speed control are as follows:

[0020] Step 1, the segmental curve of the moving speed of the extrusion rod during th...

Embodiment 2

[0025] The following is an example of an aluminum alloy product produced by a long-stroke forward aluminum extrusion machine.

[0026] Such as figure 1 As shown, the specific implementation steps of the isothermal extrusion method of this speed segmental control are as follows:

[0027] Step 1, simulate the segmental curve of the extrusion rod speed in the extrusion process; from the numerical simulation of the extrusion stroke and the extrusion rod moving speed, the extrusion rod moving speed increases along the extrusion stroke and decreases stepwise. Pressure velocity segment curve.

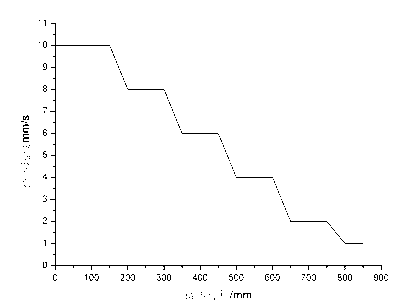

[0028] Such as figure 2 As shown, the segmentation curve of the moving speed of the whole extrusion rod is stepped, and presents a trend that the moving speed of the extrusion rod decreases with the increase of the extrusion stroke.

[0029] Specifically, the moving speed curve of the extrusion rod is divided into 6 sections within the extrusion stroke of 0-850mm, which are 10mm / s within 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com